Graphene lithium ion battery flexible positive thin-film and preparation method thereof

A technology of lithium-ion batteries and cathode thin films, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of insufficient flexibility of the cathode of lithium batteries, unsatisfactory adhesion of metal materials, and affecting battery charge and discharge performance. The effect of improving electrochemical performance, increasing the range of use, and reducing battery weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of graphene lithium ion battery flexible cathode film of the present invention is characterized in that, its steps are:

[0029] Slowly dissolve the binder in deionized water, heat to 50°C, add active materials, conductive agents, and dispersants after the binder is dissolved, and ball mill to obtain a mixed material, and coat the mixed material evenly on the PTFE plate On the surface, a film is formed, and the polytetrafluoroethylene plate coated with the film is placed in an oven, and dried at a suitable temperature, and the graphene lithium ion battery flexible cathode film obtained after drying is obtained.

[0030] Preferably, the drying temperature of the oven is 50-60° C., and the drying time is 5-10 hours.

[0031] Preferably, the weight ratio of the deionized water to the binder is 1:0.01-1:0.1.

Embodiment 1

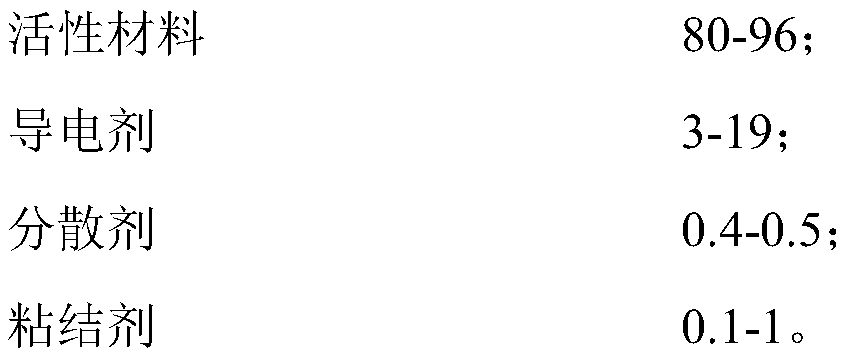

[0033] A kind of graphene lithium ion battery flexible cathode film, its raw material parts by weight are composed as follows:

[0034]

[0035]

[0036] The graphene is graphene prepared by CVD method with an average particle size of 5 μm.

[0037] The average molecular weight of the polyethylene oxide is 100,000.

[0038] Preparation method: Taking the preparation of graphene lithium ion battery flexible positive electrode film as an example, the preparation method of a graphene lithium ion battery flexible positive electrode film provided in this embodiment is described as follows:

[0039] Slowly dissolve 0.1 part of polyethylene oxide in 10 parts of deionized water, heat to 50°C, add 50 parts of lithium iron phosphate, 1 part of graphene, 0.1 part of polyvinylpyrrolidone after the polyethylene oxide is dissolved, and ball mill for 2 hours to obtain a mixed material , the mixed material is evenly coated on the surface of the polytetrafluoroethylene board to form a f...

Embodiment 2

[0041] A kind of graphene lithium ion battery flexible cathode film, its raw material parts by weight are composed as follows:

[0042]

[0043] The graphene is graphene prepared by CVD method with an average particle size of 5 μm.

[0044] The average molecular weight of the polyethylene oxide is 600,000.

[0045] Preparation method: Taking the preparation of graphene lithium ion battery flexible positive electrode film as an example, the preparation method of a graphene lithium ion battery flexible positive electrode film provided in this embodiment is described as follows:

[0046] Slowly dissolve 10 parts of polyethylene oxide in 100 parts of deionized water, heat to 50°C, add 98 parts of lithium iron phosphate, 40 parts of graphene, and 0.5 parts of polyvinylpyrrolidone after the polyethylene oxide is dissolved, and ball mill for 2 hours to obtain a mixed material , the mixed material is evenly coated on the surface of the polytetrafluoroethylene board to form a film,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com