Power battery oil-based negative electrode slurry and preparation method thereof

A negative electrode slurry and power battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of electrode sheet quality degradation, difficult to remove air bubbles, etc., and achieve shortened stirring time, reduced batching time, and uniform thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

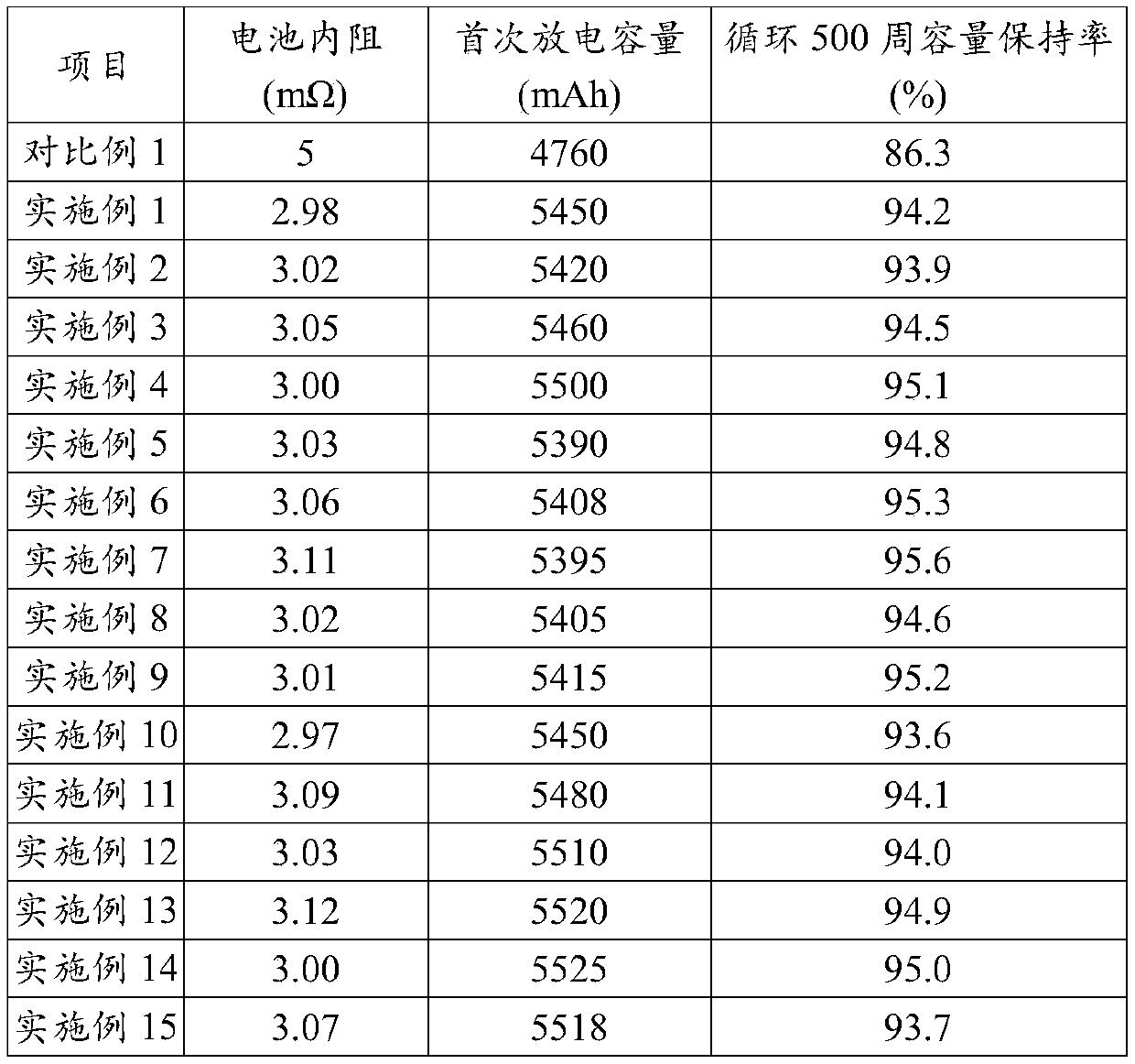

Examples

Embodiment 1

[0035] A power battery oil-based negative electrode slurry, comprising the following components by mass: 93 parts of negative electrode active materials, 1.5 parts of binder, 1 part of conductive agent, 0.05 parts of defoaming agent and 70 parts of solvent; Vinyl fluoride; the solvent is N-methylpyrrolidone; the solid content of the slurry is 50%; the viscosity of the slurry is 3000mPa.s; the negative electrode active material is natural graphite; ~10μm, D90 is 10~20μm; conductive agent is acetylene black; defoamer is ethylene carbonate.

[0036] The preparation method of the above-mentioned power battery oil-based negative electrode slurry is as follows:

[0037] S1, add all the negative electrode active material, binder, conductive agent and defoamer into the container according to the mass ratio and stir for premixing, the stirring speed is 20r / min, the rotation is 0, and the stirring time is 15min;

[0038] S2, add 80% solvent, first stir 5min at a stirring speed of 40r / m...

Embodiment 2

[0041]A power battery oil-based negative electrode slurry, comprising the following composition in parts by mass: 93.5 parts of negative electrode active material, 2 parts of binder, 1.2 parts of conductive agent, 0.08 parts of defoaming agent and 75 parts of solvent; Vinyl fluoride; the solvent is N-methylpyrrolidone; the solid content of the slurry is 54%; the viscosity of the slurry is 3500mPa.s; the negative electrode active material is artificial graphite; ~10μm, D90 is 10~20μm; conductive agent is conductive carbon black; defoamer is propylene carbonate.

[0042] The preparation method of the above-mentioned power battery oil-based negative electrode slurry is as follows:

[0043] S1, according to the mass ratio, add all the negative electrode active material, binder, conductive agent and defoamer into the container and stir for premixing. The stirring speed is 25r / min, the rotation is 0, and the stirring time is 10min;

[0044] S2, add 60% solvent, first stir for 3min ...

Embodiment 3

[0047] A power battery oil-based negative electrode slurry, comprising the following composition in parts by mass: 94 parts of negative electrode active materials, 2 parts of binder, 1.5 parts of conductive agent, 0.05 parts of defoaming agent and 80 parts of solvent; Vinyl fluoride; the solvent is N-methylpyrrolidone; the solid content of the slurry is 55%; the viscosity of the slurry is 4000mPa.s; the negative active material is mesophase carbon microspheres; the conductive agent is single-wall carbon nanotubes; defoaming The solvent is isopropanol.

[0048] The preparation method of the above-mentioned power battery oil-based negative electrode slurry is as follows:

[0049] S1, add all the negative electrode active material, binder, conductive agent and defoamer into the container according to the mass ratio and stir for premixing, the stirring speed is 30r / min, the rotation is 0, and the stirring time is 20min;

[0050] S2, add 80% solvent, first stir for 4min at a stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com