Microwave high-power material and preparation process thereof

A preparation process and high-power technology, which is applied in the field of microwave high-power materials and its preparation process, can solve problems such as huge investment, achieve low pass rate, reduce processing difficulty, and increase obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

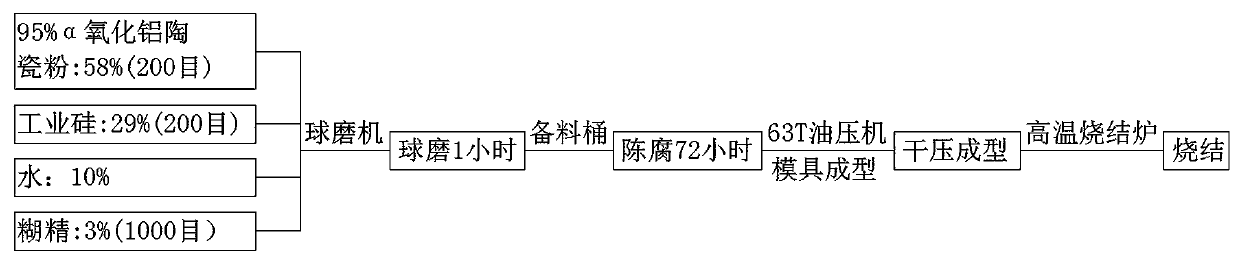

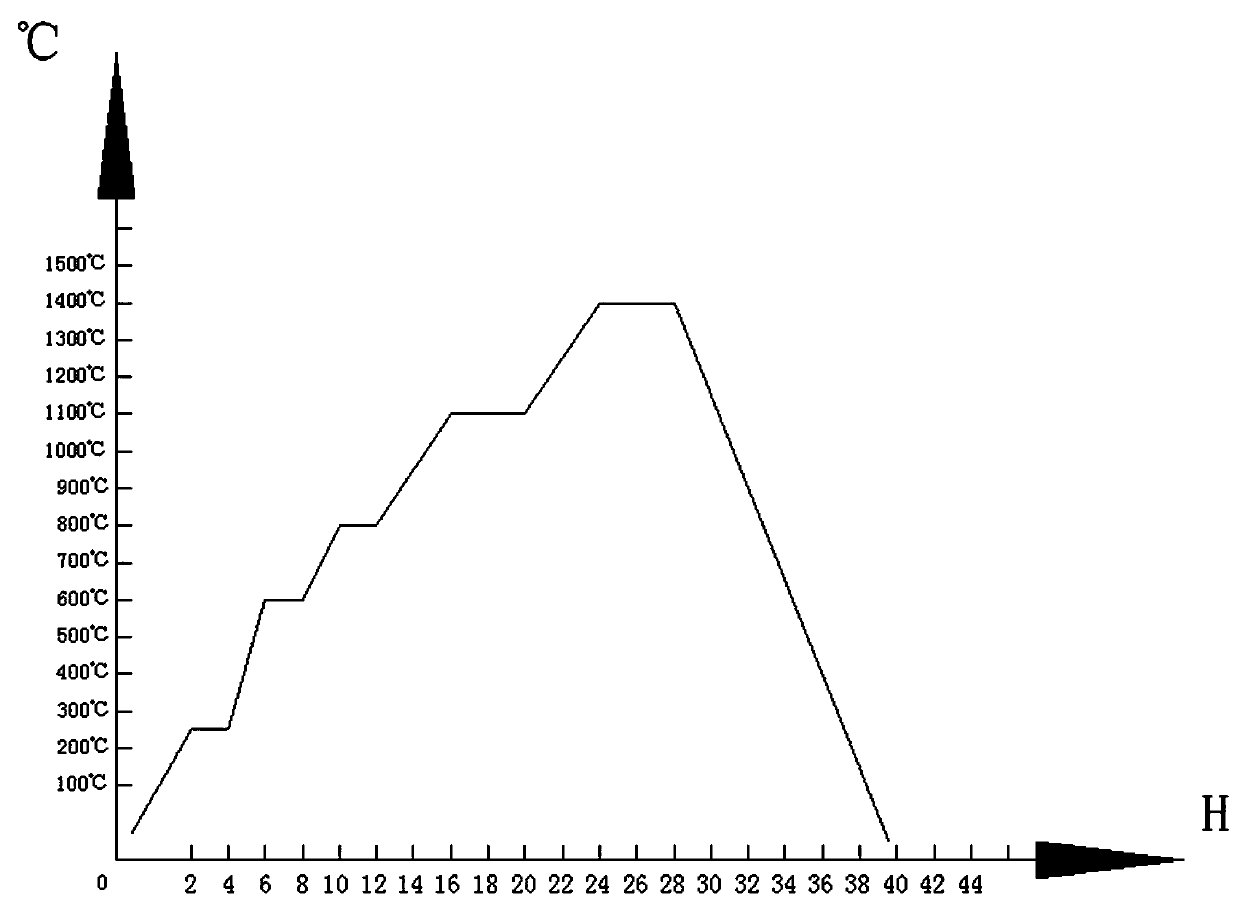

Method used

Image

Examples

Embodiment 1

[0050] The invention proposes a microwave high-power material, which has extremely high stability and wider application range under high-power conditions, and is composed of alumina ceramic powder, industrial silicon, water and dextrin.

[0051] When traditional materials such as metal cannot play a role, high-temperature stealth or high-temperature absorbing materials composed of ceramic materials and their composite materials have the advantages of good high-temperature mechanical properties and low density (about 1 / 4-1 / 3 of iron) ), stable wave-absorbing performance (resistance-type wave-absorbing and resistance increases with temperature more stable, no electromagnetic loss attenuation and yield effect), can also effectively weaken the infrared radiation signal; the present invention uses ceramic (95% α alumina) base Industrial silicon is the main component to produce high-power absorbing materials.

Embodiment 2

[0053] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, in order to better realize a microwave high-power material described in the present invention, the following setting method is specially adopted: the raw material ratio of the microwave high-power material Calculated as a percentage by weight:

[0054]

Embodiment 3

[0056] This embodiment is further optimized on the basis of Embodiment 1 or 2. Further, in order to better realize a microwave high-power material described in the present invention, the following setting method is specially adopted: the raw material of the microwave high-power material Proportioning is calculated by weight percentage as:

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com