Composite ceramic fluophor for high-power laser illumination, preparation method of composite ceramic fluophor and light source device

A technology of composite ceramics and laser lighting, applied in the laser field, can solve immature problems, achieve stable color temperature, improve thermal conductivity and color rendering index, and excellent luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

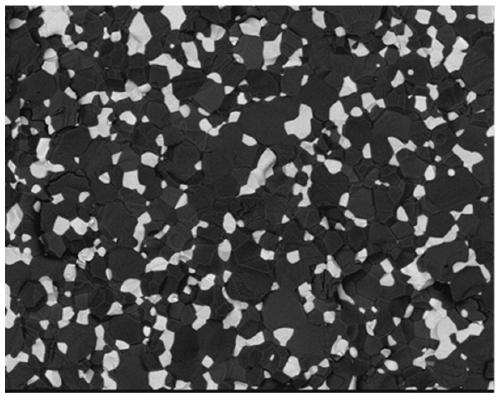

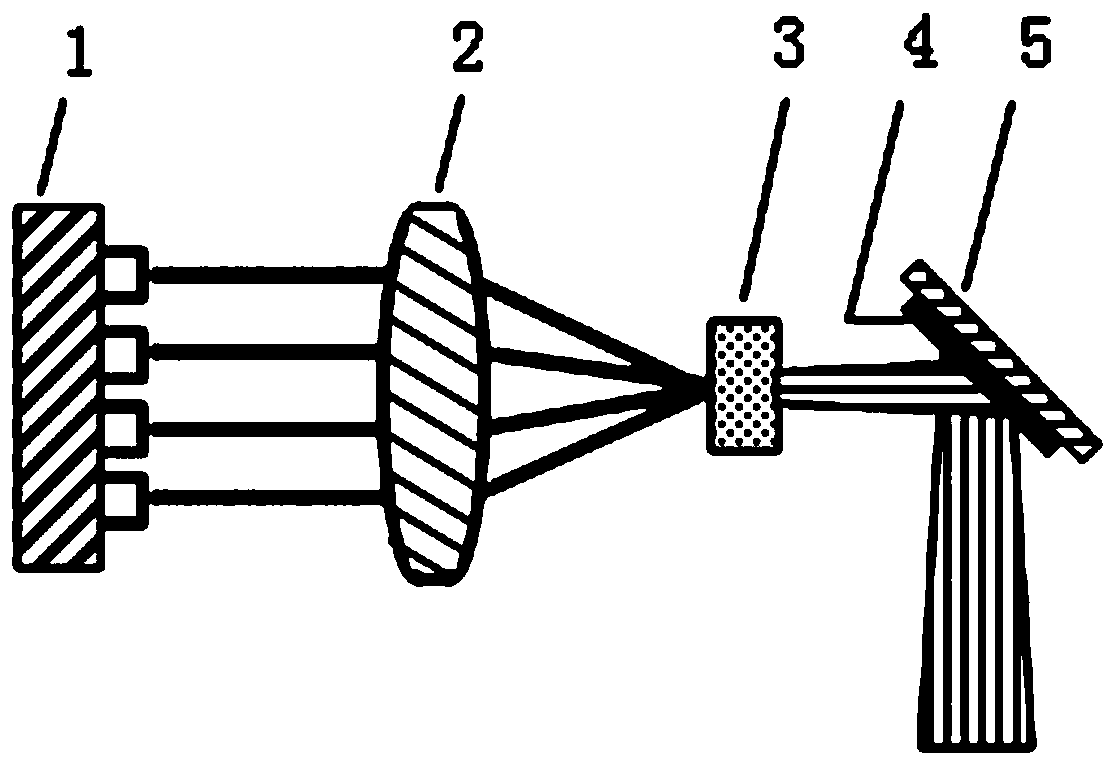

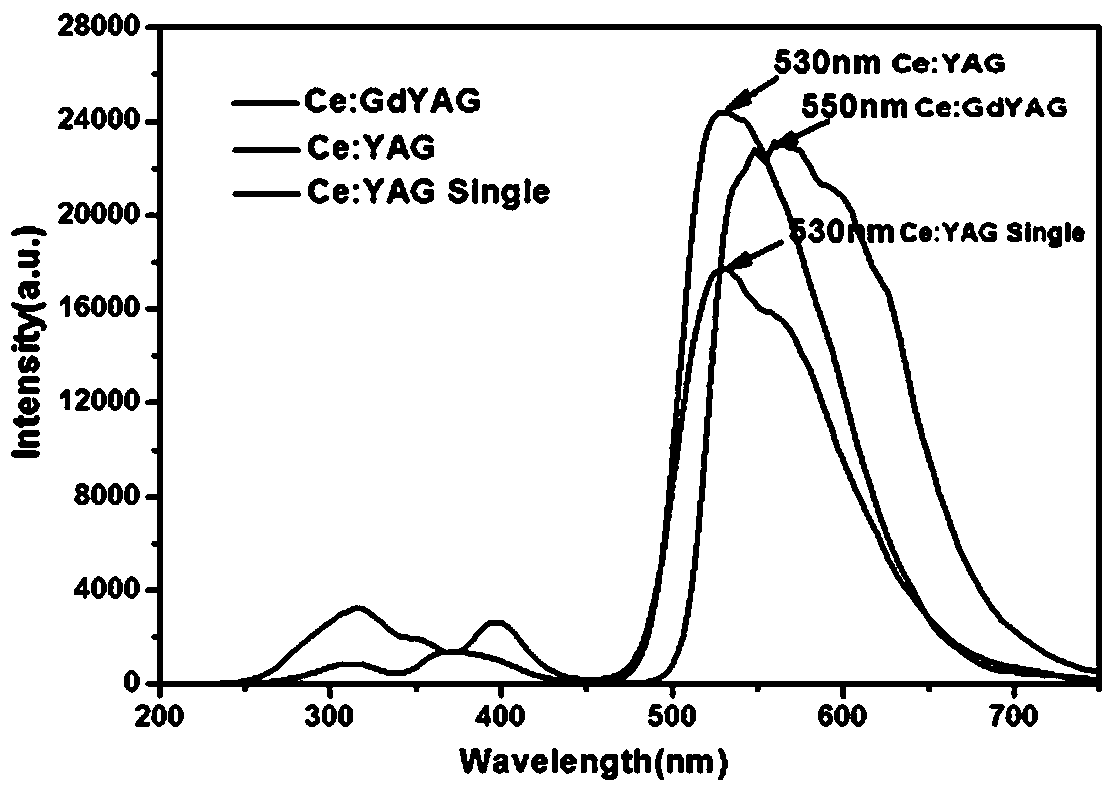

[0033] to Y 2 o 3 、Gd 2 o 3 , CeO 2 and Al(NO 3 ) 3 •9H 2 O is used as a raw material to prepare a nitrate solution, respectively according to (Ce 0.008 Y 0.992 ) 3 Al 5 o 12 , (Ce 0.008 Gd 0.50 Y 0.492 ) 3 Al 5 o 12 The chemical ratio of the transparent ceramics is mixed with the corresponding nitrate solution, and the fluorescent powder with a particle size in the range of 50-200nm is synthesized by hydrothermal method and kept at 150°C for 10 hours. Ce:YAG powder, Ce,Gd:YAG powder were mixed with commercial nano-Al 2 o 3 The powder (particle size 50nm) is mixed according to the mass ratio of 50%:50%, 50%:50%, and then a certain amount of sintering aids, linking agents, plasticizers, and dispersants are added as additives. Ball milling in a ball mill prepares a uniformly mixed slurry. After the slurry is vacuum defoamed, it is sequentially poured into a tape casting machine for tape casting to obtain a double-layer composite cast sheet; the double-layer c...

Embodiment 2

[0036] Adjust Ce:YAG powder, Ce,Gd:YAG powder and commercial nano-Al 2 o 3 The powder (particle size is about 50nm) is mixed according to the mass ratio of 60%:40%, 40%:60%, and other conditions are the same as in Example 1. It can also be excited and recombined under the blue laser LD. The light emitting device can obtain the highest Irradiation power density up to 15W / mm 2 , high-quality white light with a color temperature of 4772K and a photoelectric efficiency of 147lm / W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com