Soil stabilizer, and preparation and applications thereof

A soil curing agent and soil technology, applied in the direction of chemical instruments and methods, applications, soil conditioning materials, etc., can solve the problems of easy strength reduction when exposed to water, complicated retrieving methods, slow degradation speed, etc., to achieve no toxic side effects, source Broad, penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The soil solidifying agent of the present embodiment is made through the following steps:

[0023] Inject 1000kg of clean drinking water into the enamel reaction kettle with heating system, reflux condensation and stirring device, heat up to 60°C, add 30kg of sodium alginate (the average molecular weight is 200,000-240,000), and stir for 30 minutes , heating to raise the temperature in the reactor to 75°C, and keep it warm for 1 hour under this condition (take a sample before discharging, observe whether the product is a completely transparent viscous aqueous solution, if not, extend the holding time accordingly), and then cool to 40°C, discharge the material, put it into a plastic bucket, it is a soil curing agent for soil consolidation, anti-seepage and anti-erosion.

Embodiment 2

[0025] The soil solidifying agent of the present embodiment is made through the following steps:

[0026] Inject 1000kg of clean drinking water into the enamel reaction kettle with heating system, reflux condensation and stirring device, heat up to 55°C, and divide 20kg of sodium alginate (with an average molecular weight of 200,000 to 240,000) into two batches Add in clean drinking water, stir for 17 minutes after each addition, heat to raise the temperature in the reactor to 70°C, keep warm for 0.5 hours under this condition until the product is a completely transparent viscous hydrogel, cool to 50°C, The material is discharged and put into a plastic bucket, which is a soil curing agent for soil stabilization, anti-seepage and anti-erosion.

Embodiment 3

[0028] The soil solidifying agent of the present embodiment is made through the following steps:

[0029] First inject 1000kg of clean drinking water into the enamel reaction kettle with heating system, reflux condensation and stirring device, heat up to 65°C, and divide 10kg of sodium alginate (the average molecular weight is 200,000 to 240,000) into two batches Add clean drinking water, stir for 23 minutes after each addition, heat the temperature in the reactor to 80°C, keep warm for 1 hour under this condition until the product is a completely transparent viscous hydrogel, cool to 45°C, The material is discharged and put into a plastic bucket, which is a soil curing agent for soil stabilization, anti-seepage and anti-erosion.

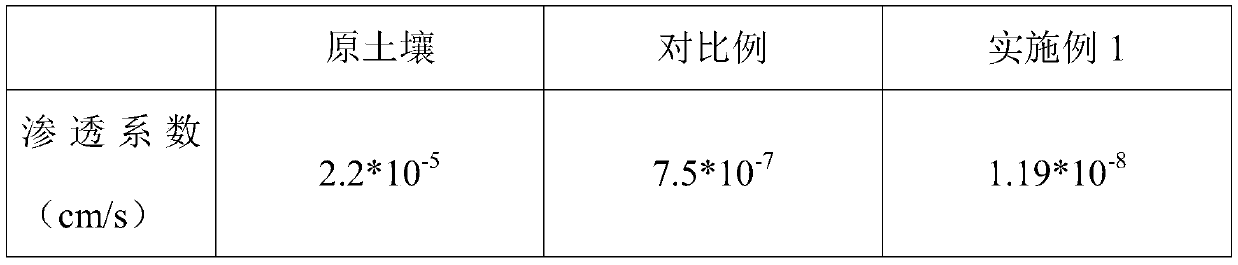

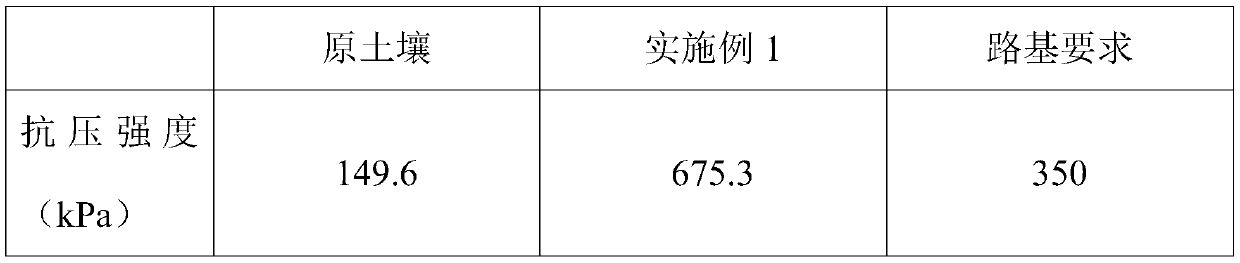

[0030] The soil curing agents prepared in the above-mentioned Examples 1 to 3 all use sodium alginate as an active ingredient, and the soil curing agents can be used for curing soil, improving soil impermeability and erosion resistance, that is, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com