Anhydrous total-synthesis fire-retardant hydraulic fluid and synthesizing method thereof

A synthetic method and a fully synthetic technology, applied in the field of hydraulic fluids, can solve problems such as poor lubricity and easily corroded metals, and achieve the effects of improving stability, strong corrosion resistance, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] On the other hand, the embodiment of the present invention also provides a method for synthesizing anhydrous fully synthetic flame retardant hydraulic fluid, the steps of which are as follows:

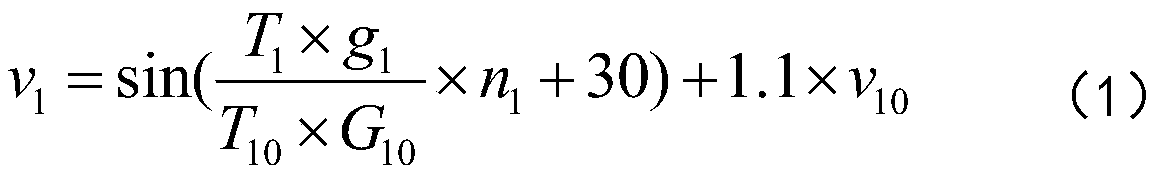

[0045] Step a, the reactor is rinsed clean, the discharge valve is closed, and the paraffin, liquid rosin, acetone and triethanolamine are started to stir in the reactor to make it fully react, and the stirring speed is determined according to the following formula (1),

[0046]

[0047] In the formula, v 1 Indicates the stirring speed of the first stage, T 1 Indicates the temperature of the mixed liquid in the first stage; T 10 Indicates the preset temperature value of the first stage, the temperature value is 28°C; g 1 Indicates the mass of paraffin wax added in the first stage, G 10 Indicates the total mass of the mixed liquid in the first stage; n 1 Represents the specific heat capacity of liquid rosin; v 10 Indicates the preset stirring speed of the first stage, whi...

Embodiment 1

[0062] The anhydrous fully synthetic flame retardant hydraulic fluid described in this embodiment includes the following components in parts by weight: 5 parts of paraffin, 20 parts of liquid rosin, 3 parts of anhydrous lanolin, 8 parts of coconut acid diethanolamide, three 10 parts of ethanolamine, 5 parts of benzotriazole, 5 parts of dibutyl succinate, 40 parts of acetone, 10 parts of emulsifier, 4 parts of coolant, 5 parts of corrosion inhibitor, 6 parts of antifoaming agent, 3 parts of surfactant share.

Embodiment 2

[0064] The anhydrous fully synthetic flame retardant hydraulic fluid described in this embodiment includes the following components in parts by weight: 6 parts of paraffin wax, 23 parts of liquid rosin, 4 parts of anhydrous lanolin, 10 parts of coconut acid diethanolamide, three 13 parts of ethanolamine, 7 parts of benzotriazole, 9 parts of dibutyl succinate, 46 parts of acetone, 13 parts of emulsifier, 6 parts of coolant, 7 parts of corrosion inhibitor, 8 parts of antifoaming agent, 4 parts of surfactant share.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com