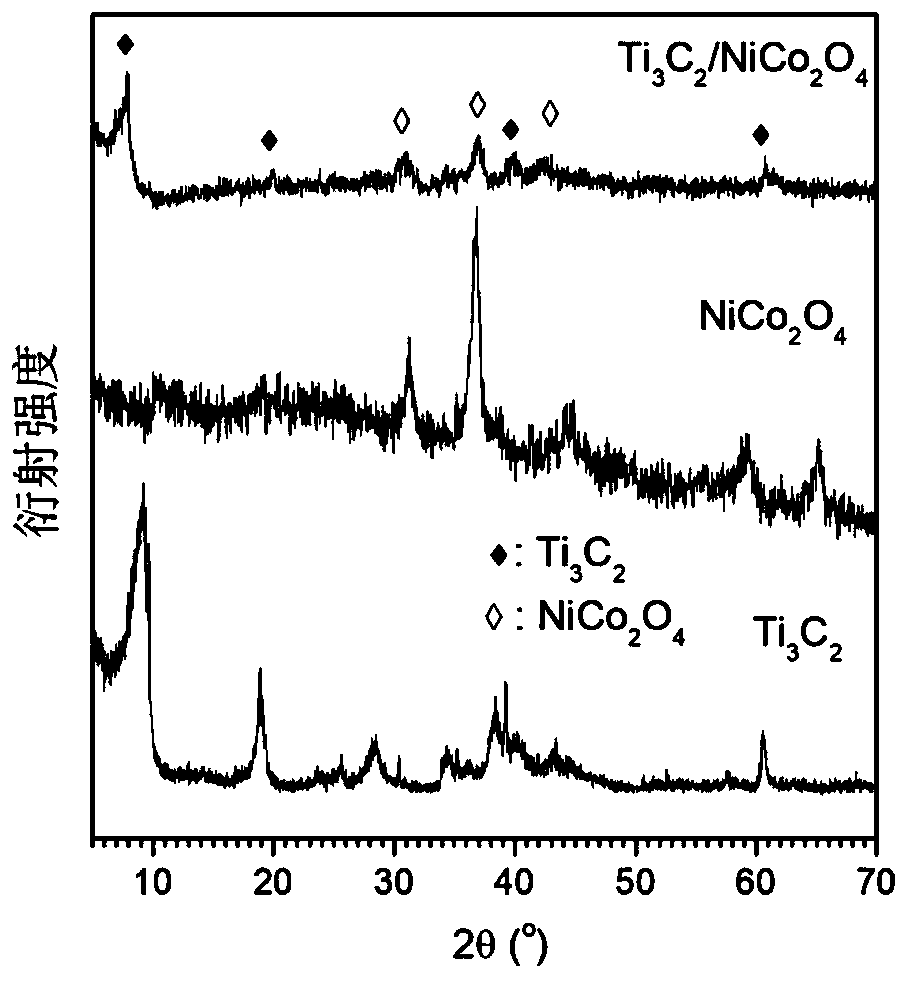

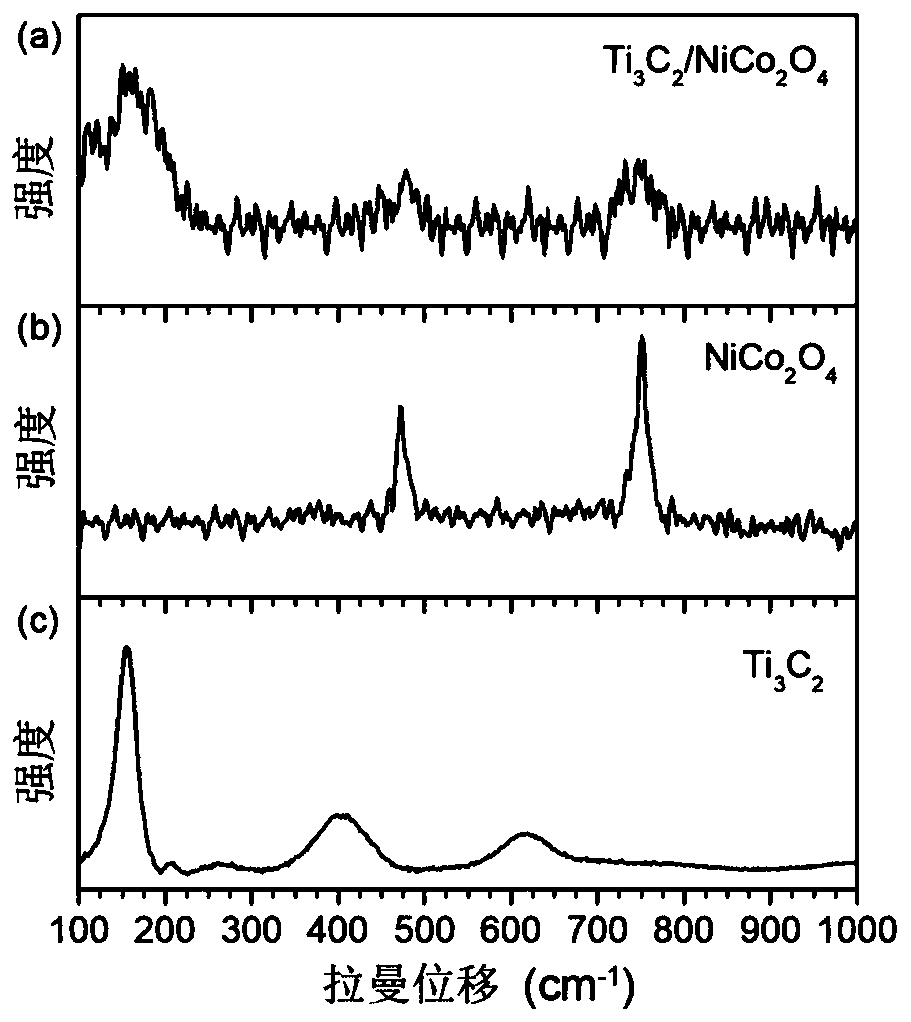

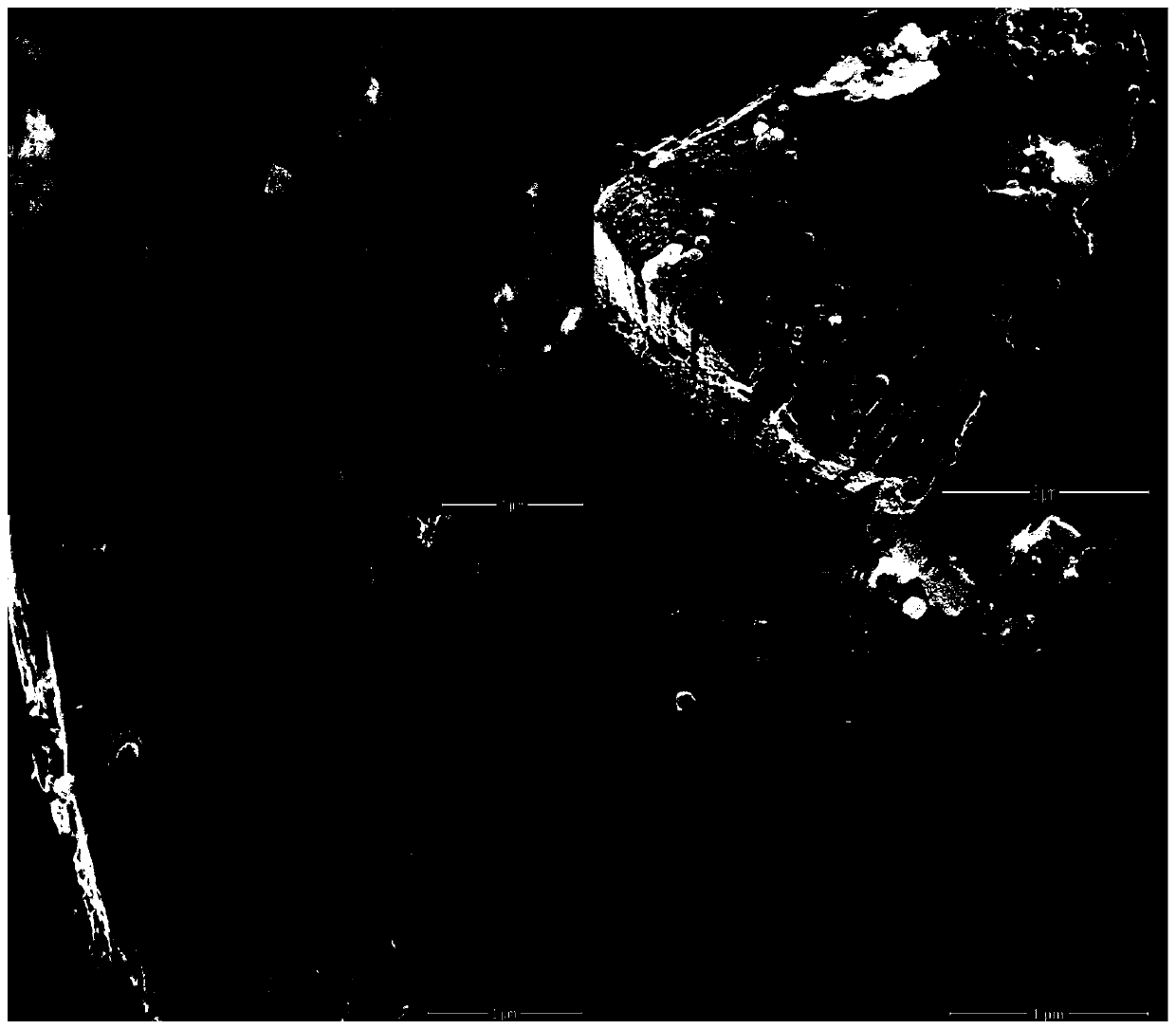

Ti3C2/NiCo2O4 composite electrode material and preparation method thereof

A composite electrode and hydrate technology, applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as electrochemical performance needs to be improved, sheets are easy to accumulate and superimpose, and specific surface area is small , to achieve excellent electrochemical performance, low cost, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) 1g Ti 3 C 2 The powder was added to 200mL dimethyl sulfoxide and sonicated for 2 hours, centrifuged, washed with ethanol for 6 times, and dried in vacuum for later use;

[0029] (2) Weigh 0.481g (2.870mmol) of Ti which will be pretreated in step (1) 3 C 2 Add the powder into 80mL ethylene glycol, stir well for 1h to disperse; weigh 2mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and 4 mmol cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) join in the above-mentioned solution, continue to stir 2h; Take by weighing 2g polyvinylpyrrolidone (namely according to C 6 h 9 NO single molecule is calculated as mole 18mmol), joins in the above-mentioned solution, continues to stir 1h; Takes 18mmol urea and slowly adds in the solution, obtains suspension liquid; (illustration, in the embodiment of the present invention, molar ratio Ti 3 C 2 :Ni ion=1:0.348~2.091, to ensure Ti in the final product 3 C 2 and NiCo 2 o 4 The mass ratio is 1:0.5~3;)

[0030] (3...

Embodiment 2、3

[0038] Change the hydrothermal reaction temperature of step (3) in Example 1 to 160 and 200°C, and other operations are the same as in Example 1, and the product obtained is the same as in Example 1.

Embodiment 4、5

[0040] Change the hydrothermal reaction time of step (3) in Example 1 to 2 and 16h, and other other operations are the same as in Example 1, and the product obtained is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com