Electroforming liquid for gold cyanide-free electroforming process

An electroforming fluid and electroforming technology, applied in electroforming, electrolysis process, etc., can solve the problems of not being widely put into production, unable to meet demand, etc., and achieve the effect of simplifying electroforming fluid components, easy preparation, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

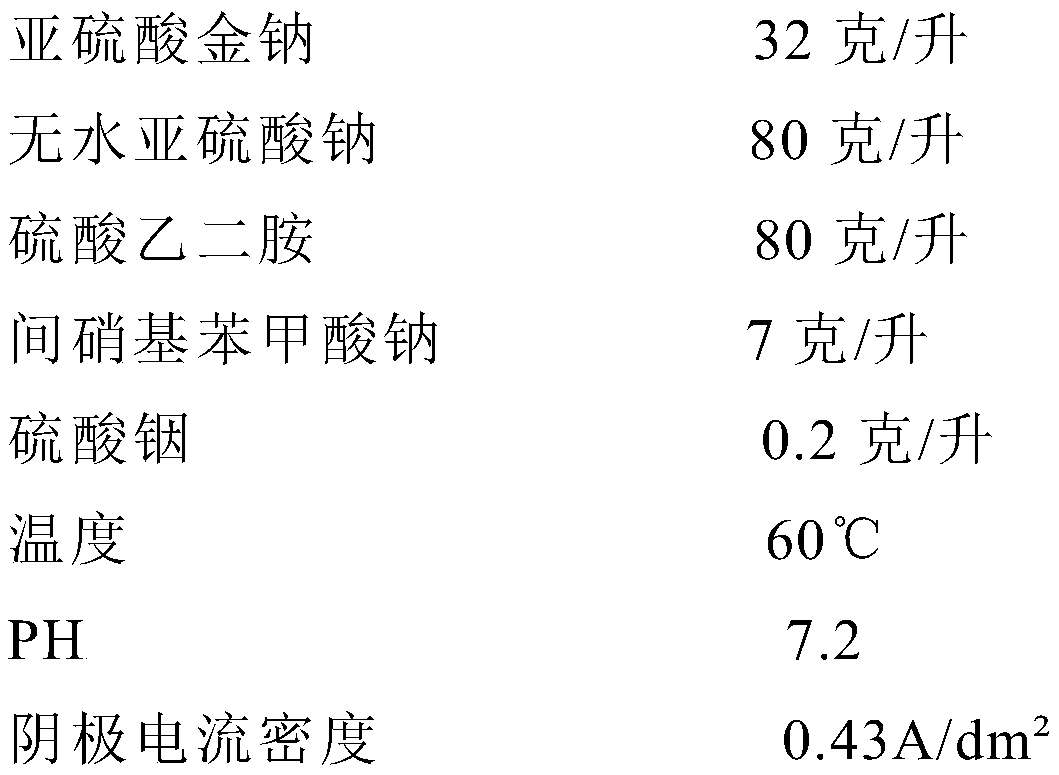

[0038] The electroforming solution formula is as follows:

[0039]

[0040] Electroformed according to the recipe, using 0.43A / dm 2 The cathode current density, electroforming time 10 hours.

[0041] A thick gold product with a thickness of 180um, a mass fraction of 99.95%, and a micro-Vickers hardness of 110HV can be obtained. The surface is bright and smooth, and the color is golden and bright. The casting layer has excellent toughness.

Embodiment 2

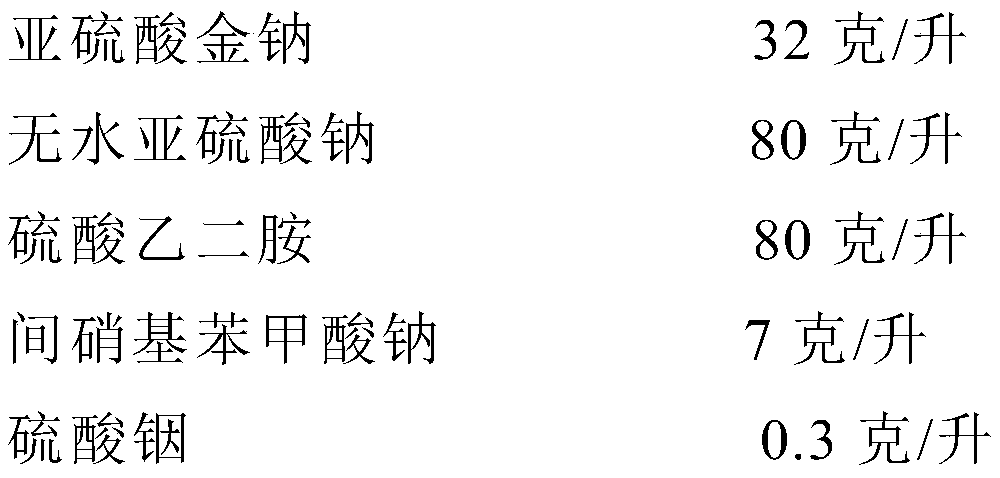

[0043] The electroforming solution formula is as follows:

[0044]

[0045]

[0046] Electroformed according to the recipe, using 0.43A / dm 2 The cathode current density, electroforming time 10 hours.

[0047] A thick gold product with a thickness of 180um, a mass fraction of 99.94%, and a micro-Vickers hardness of 125HV can be obtained. The surface is bright and smooth, and the color is golden and bright. The casting layer has excellent toughness.

Embodiment 3

[0049] The electroforming solution formula is as follows:

[0050]

[0051] Electroformed according to the recipe, using 0.43A / dm 2 The cathode current density, electroforming time 10 hours.

[0052] A thick gold product with a thickness of 180um, a mass fraction of 99.93%, and a micro-Vickers hardness of 145HV can be obtained. The surface is bright and smooth, and the color is golden and bright. The casting layer has good toughness.

[0053] (4) Embodiment 4

[0054] The electroforming solution formula is as follows:

[0055]

[0056]

[0057] Electroformed according to the recipe, using 0.43A / dm 2 The cathode current density, electroforming time 10 hours.

[0058] A thick gold product with a thickness of 180 microns, a mass fraction of 99.92%, and a micro-Vickers hardness of 165HV can be obtained. The surface is bright and smooth, and the color is golden and bright. The casting layer has certain toughness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Micro vickers hardness | aaaaa | aaaaa |

| Micro vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com