Production method of high response ultraviolet detector

A technology of ultraviolet detector and manufacturing method, which is applied in the field of semiconductor device preparation, can solve problems such as device performance degradation, and achieve the effects of reducing and photoconductive gain, reducing dark current, and reducing material defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] 1. Production equipment and materials:

[0028] 1. Planetary disk type 4-inch 11-piece metal-organic chemical vapor deposition MOCVD preparation system.

[0029] 2. Trimethylgallium (TMGa) and trimethylaluminum (TMAl) are used as metal organic MO growth sources of gallium and aluminum in the MOCVD growth process, ammonia (NH 3 ) as a nitrogen source, MO source into the auxiliary gas path: the growth source and the auxiliary gas path are input into the MOCVD reaction chamber through independent pipes and systems.

[0030] 3. Plasma enhanced chemical vapor deposition (PECVD) is used to deposit silicon dioxide (or silicon nitride, etc.) materials.

[0031] 4. Electron beam evaporation is used for evaporating Ti, Al, Ni, Au and other metal thin films.

[0032] 2. Specific steps:

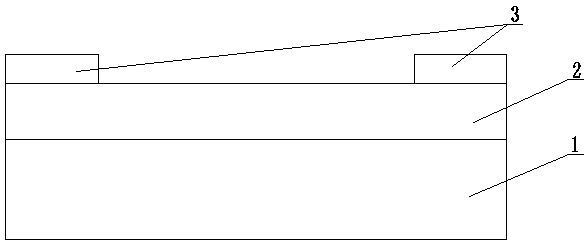

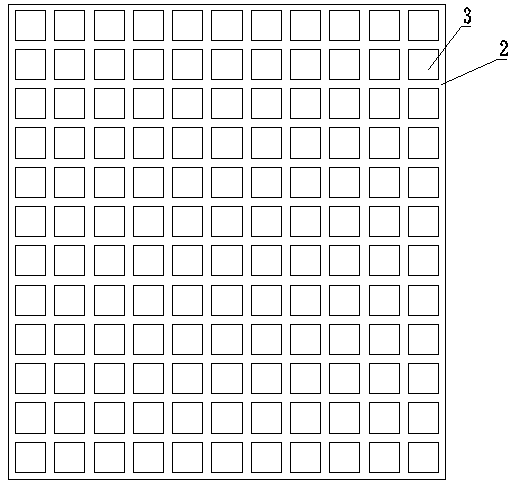

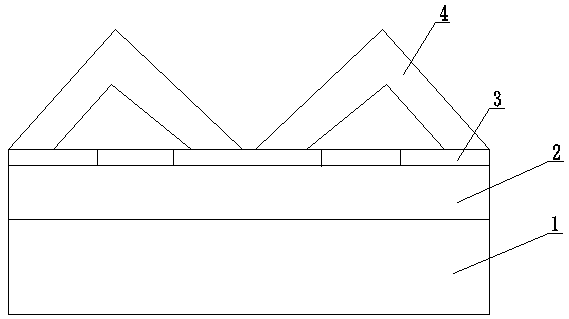

[0033] refer to Figure 1~3 , based on semipolar Al x Ga 1-x The specific process steps of the N material MSM ultraviolet detection device structure are as follows.

[0034] Step 1: First, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com