Moringa leaf extract with cholate adsorption capacity and preparation method and application thereof

A technology of adsorption ability and moringa leaf, applied in the field of moringa leaf extract with cholate adsorption ability and its preparation, and in the field of moringa leaf extract, achieving good cholate adsorption ability and simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

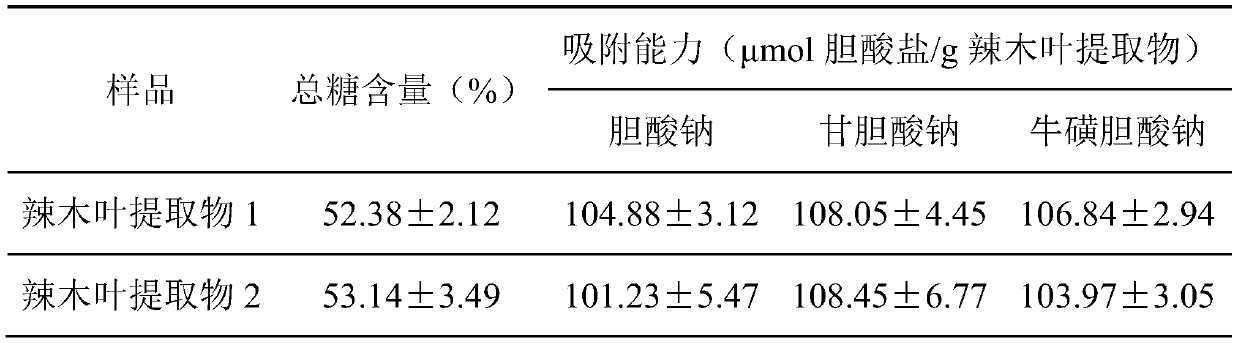

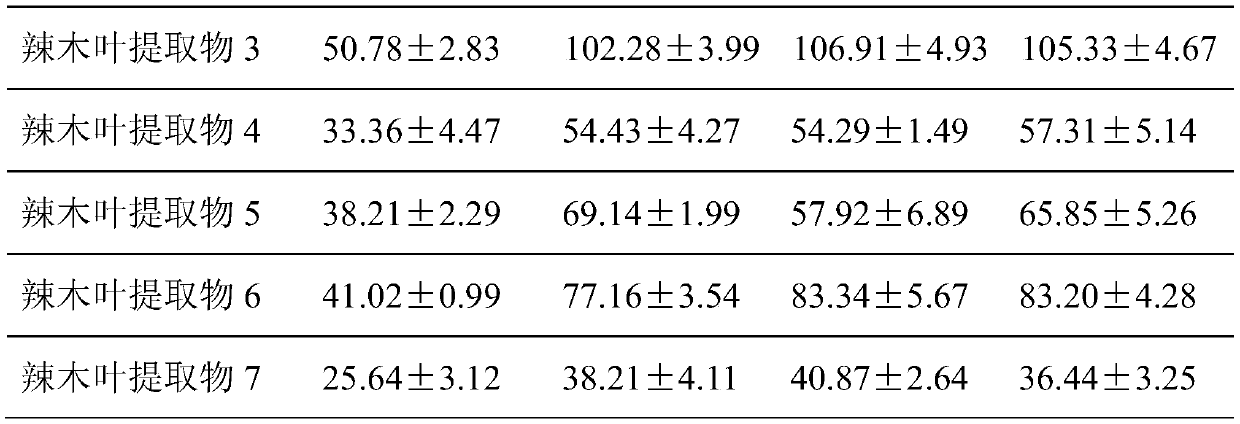

Embodiment 1

[0056] A kind of Moringa oleifera leaf extract with cholate adsorption ability, specifically comprises the steps:

[0057] (1) Crushing and sieving: crush the dried Moringa leaves and pass through a 40-mesh sieve to obtain Moringa leaves dry powder 1 .

[0058] (2) Ethanol hot reflux to remove impurities: mix Moringa oleifera leaf dry powder 1 obtained in step (1) with absolute ethanol at a material-to-liquid ratio of 1:8g / mL, heat to 85°C for reflux extraction for 2 hours, remove the liquid, and precipitate at 45°C Dry for 4 hours to get Moringa leaf dry powder 2.

[0059] (3) Add water for homogenization: Moringa oleifera leaf dry powder 2 and deionized water are mixed with a material-to-liquid ratio of 1:10g / mL for homogeneous homogenization. During homogenization, the shear rate is 3000rpm, and the shear time is 10min. Suspension 1.

[0060] (4) Ultrasonic treatment: The suspension 1 obtained in step (3) was subjected to constant temperature ultrasonic treatment at 40° C...

Embodiment 2

[0070] A kind of Moringa oleifera leaf extract with cholate adsorption ability, specifically comprises the steps:

[0071] (1) Crushing and sieving: crush the dried Moringa leaves and pass through a 60-mesh sieve to obtain Moringa leaves dry powder 1 .

[0072] (2) Ethanol hot reflux to remove impurities: mix Moringa oleifera leaf dry powder 1 obtained in step (1) with absolute ethanol at a material-to-liquid ratio of 1:12g / mL, heat to 90°C for reflux extraction for 2.5h, remove the liquid, and precipitate for 55 ℃ drying for 5 hours to obtain Moringa leaf dry powder 2.

[0073] (3) Add water for homogenization: Moringa oleifera leaf dry powder 2 is mixed with deionized water at a material-to-liquid ratio of 1:14g / mL, homogeneously homogenized, the shear rate during homogenization is 4000rpm, and the shear time is 15min to obtain a suspension Liquid 1.

[0074] (4) Ultrasonic treatment: The suspension 1 obtained in step (3) was subjected to constant temperature ultrasonic tr...

Embodiment 3

[0084] A kind of Moringa oleifera leaf extract with cholate adsorption ability, specifically comprises the steps:

[0085] (1) Crushing and sieving: crush the dried Moringa leaves and pass through an 80-mesh sieve to obtain Moringa leaves dry powder 1 .

[0086] (2) Ethanol hot reflux to remove impurities: mix Moringa oleifera leaf dry powder 1 obtained in step (1) with absolute ethanol at a material-to-liquid ratio of 1:16g / mL, heat to reflux at 95°C for 3 hours, remove the liquid, and precipitate at 65°C Dry for 6 h to get Moringa leaf dry powder 2.

[0087] (3) Add water for homogenization: Moringa oleifera leaf dry powder 2 is mixed with deionized water at a material-to-liquid ratio of 1:18g / mL, homogeneously homogenized, the shear rate during homogenization is 5000rpm, and the shear time is 20min to obtain a suspension Liquid 1.

[0088] (4) Ultrasonic treatment: The suspension 1 obtained in step (3) was ultrasonically treated at a constant temperature of 60° C. for 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com