A kind of Moringa oleifera leaf extract with cholate adsorption capacity and its preparation method and application

A technology of adsorption capacity and Moringa leaves, which is applied in the deep processing and high-value fields of Moringa leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

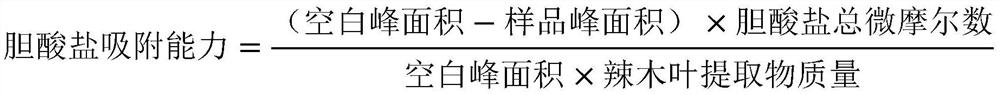

Image

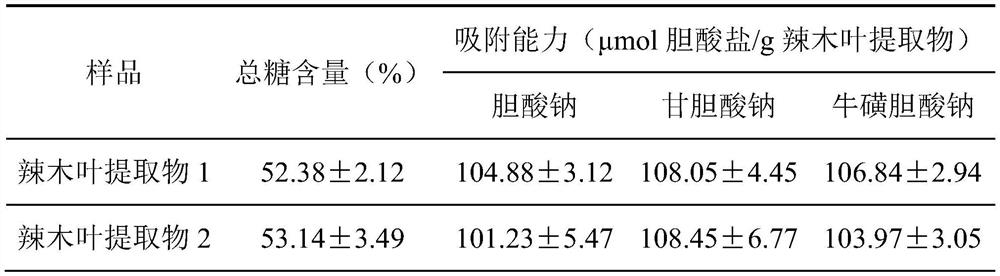

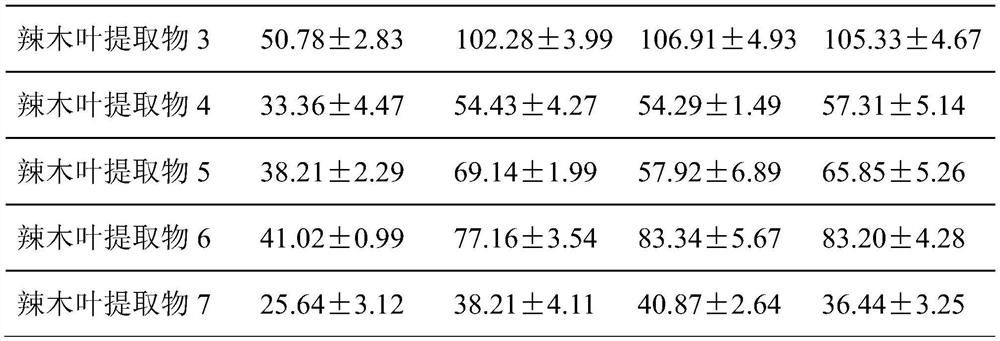

Examples

Embodiment 1

[0056] A kind of Moringa oleifera leaf extract with cholate adsorption ability, specifically comprises the steps:

[0057] (1) Crushing and sieving: crush the dried Moringa leaves and pass through a 40-mesh sieve to obtain Moringa leaves dry powder 1 .

[0058] (2) Ethanol hot reflux to remove impurities: mix Moringa oleifera leaf dry powder 1 obtained in step (1) with absolute ethanol at a material-to-liquid ratio of 1:8g / mL, heat to 85°C for reflux extraction for 2 hours, remove the liquid, and precipitate at 45°C Dry for 4 hours to get Moringa leaf dry powder 2.

[0059] (3) Add water for homogenization: Moringa oleifera leaf dry powder 2 and deionized water are mixed with a material-to-liquid ratio of 1:10g / mL for homogeneous homogenization. During homogenization, the shear rate is 3000rpm, and the shear time is 10min. Suspension 1.

[0060] (4) Ultrasonic treatment: The suspension 1 obtained in step (3) was subjected to constant temperature ultrasonic treatment at 40° C...

Embodiment 2

[0070] A kind of Moringa oleifera leaf extract with cholate adsorption ability, specifically comprises the steps:

[0071] (1) Crushing and sieving: crush the dried Moringa leaves and pass through a 60-mesh sieve to obtain Moringa leaves dry powder 1 .

[0072] (2) Ethanol hot reflux to remove impurities: mix Moringa oleifera leaf dry powder 1 obtained in step (1) with absolute ethanol at a material-to-liquid ratio of 1:12g / mL, heat to 90°C for reflux extraction for 2.5h, remove the liquid, and precipitate for 55 Dry at ℃ for 5 hours to obtain dry powder of Moringa oleifera leaves 2.

[0073] (3) Add water for homogenization: Moringa oleifera leaf dry powder 2 is mixed with deionized water at a material-to-liquid ratio of 1:14g / mL, homogeneously homogenized, the shear rate during homogenization is 4000rpm, and the shear time is 15min to obtain a suspension Liquid 1.

[0074] (4) Ultrasonic treatment: The suspension 1 obtained in step (3) was subjected to constant temperature...

Embodiment 3

[0084] A kind of Moringa oleifera leaf extract with cholate adsorption ability, specifically comprises the steps:

[0085] (1) Crushing and sieving: crush the dried Moringa leaves and pass through an 80-mesh sieve to obtain Moringa leaves dry powder 1 .

[0086] (2) Ethanol hot reflux to remove impurities: mix Moringa oleifera leaf dry powder 1 obtained in step (1) with absolute ethanol at a material-to-liquid ratio of 1:16g / mL, heat to reflux at 95°C for 3 hours, remove the liquid, and precipitate at 65°C Dry for 6 h to get Moringa leaf dry powder 2.

[0087] (3) Add water for homogenization: Moringa oleifera leaf dry powder 2 is mixed with deionized water at a material-to-liquid ratio of 1:18g / mL, homogeneously homogenized, the shear rate during homogenization is 5000rpm, and the shear time is 20min to obtain a suspension Liquid 1.

[0088] (4) Ultrasonic treatment: The suspension 1 obtained in step (3) was ultrasonically treated at a constant temperature of 60° C. for 1.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com