Modified bentonite, application thereof, modified bentonite granule, and heavy metal adsorbent

A bentonite and modified technology, which is applied in the field of deep processing of bentonite and heavy metal pollution control, can solve the problems of poor adsorption performance of heavy metals, and achieve the effects of fast adsorption rate, excellent heavy metal adsorption performance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

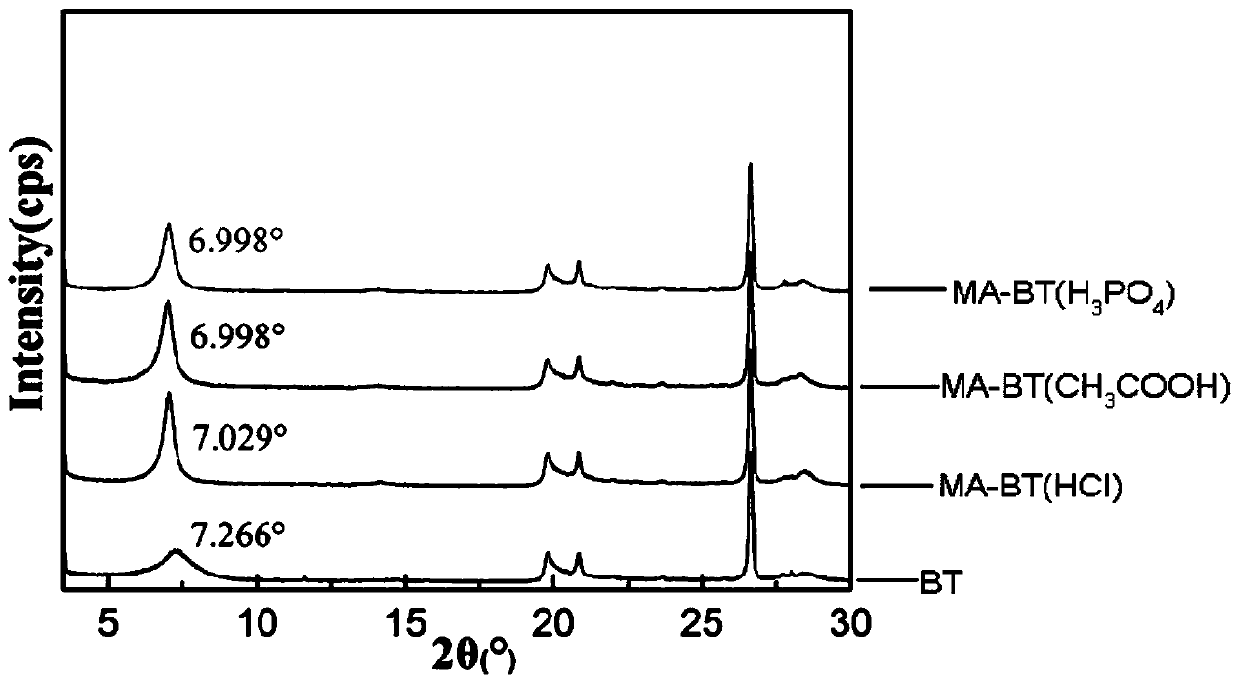

[0033] Example 1: Preparation of modified bentonite by reaction of melamine and bentonite under different acidic medium conditions

[0034] The specific operation steps are as follows:

[0035] a, dilute concentrated hydrochloric acid, glacial acetic acid, concentrated nitric acid or concentrated sulfuric acid with distilled water respectively, be mixed with the solution that volume percent concentration is 2%, boric acid is dissolved with distilled water, be mixed with the solution that the mass fraction concentration is 5%.

[0036] b. Dissolve 1.9281g of melamine in 300mL of the solution obtained in step a;

[0037] c, add 10.00g bentonite to the solution obtained in step b (cation exchange capacity is 1.0179mmol / g);

[0038] d. Fully heating and stirring the mixture obtained in step c at 80°C for 8 hours;

[0039] e, the reaction mixture obtained in step d is suction filtered while hot, and the filter cake is washed 3 times with hot water;

[0040] f, the filter cake ob...

Embodiment 2

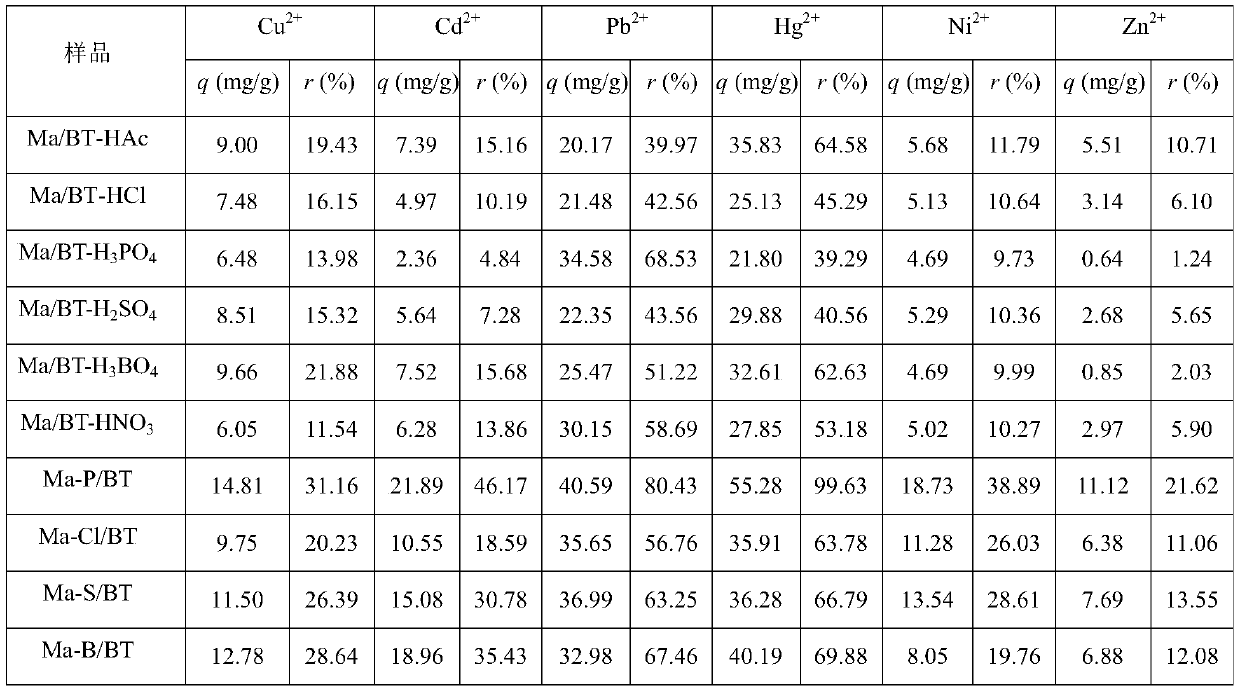

[0043] Embodiment two: prepare modified bentonite with melamine salt compound and bentonite reaction in aqueous solution

[0044] The specific operation steps are as follows:

[0045] a, 10.00g (cation exchange capacity is 1.0179mmol / g) bentonite is mixed with 400mL water to prepare slurry;

[0046] B, fully stirring and dispersing the bentonite slurry obtained in step a;

[0047] c. Add 0.015mol melamine phosphate (purity ≥ 99%, Nanjing Senbega Biotechnology Co., Ltd.), 0.015mol melamine hydrochloride (purity ≥ 99%, Hubei Giant) respectively to the uniformly dispersed bentonite slurry obtained in step b. Sheng Technology Co., Ltd.), 0.015mol melamine borate (purity ≥99%, Taian Jiaye Biotechnology Co., Ltd.) and 0.015mol melamine sulfate (purity ≥97%, Nanjing Kangmanlin Chemical Industry Co., Ltd.);

[0048] d. Fully heating and stirring the mixture obtained in step c at 70°C for 8 hours;

[0049] e, the reaction mixture obtained in step d is suction filtered while hot, and...

Embodiment 3

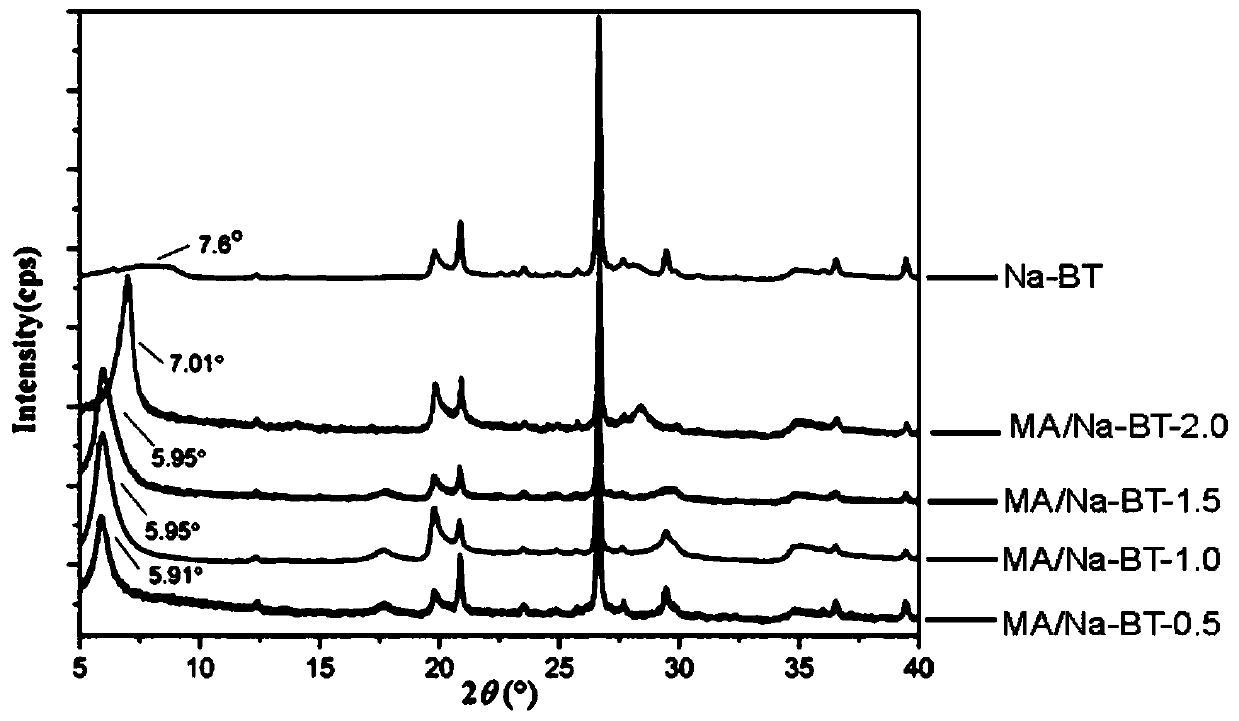

[0052] Example 3: Prepare modified bentonite by reacting different amounts of melamine phosphate and bentonite in aqueous solution

[0053] The specific operation steps are as follows:

[0054] a, 10.00g (cation exchange capacity is 1.0179mmol / g) bentonite is mixed with 400mL water to prepare slurry;

[0055] B, fully stirring and dispersing the bentonite slurry obtained in step a;

[0056] c. Add 0.005mol, 0.010mol, 0.015mol, 0.020mol melamine phosphate (purity ≥ 99%, Nanjing Senbega Biotechnology Co., Ltd.) to the uniformly dispersed bentonite slurry obtained in step b respectively;

[0057] d. Fully heating and stirring the mixture obtained in step c at 80°C for 8 hours;

[0058] e, the reaction mixture obtained in step d is suction filtered while hot, and the filter cake is washed 3 times with hot water;

[0059] f, the filter cake obtained in step e is transferred to a drying oven for drying;

[0060] g. Grinding and sieving the dried sample obtained in step f to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com