A kind of catalyst-containing carbon-coated mg-based hydrogen storage material and preparation method thereof

A technology for hydrogen storage materials and catalysts, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as low hydrogen storage capacity, improve hydrogen storage performance, simplify the process, and improve hydrogen storage kinetic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

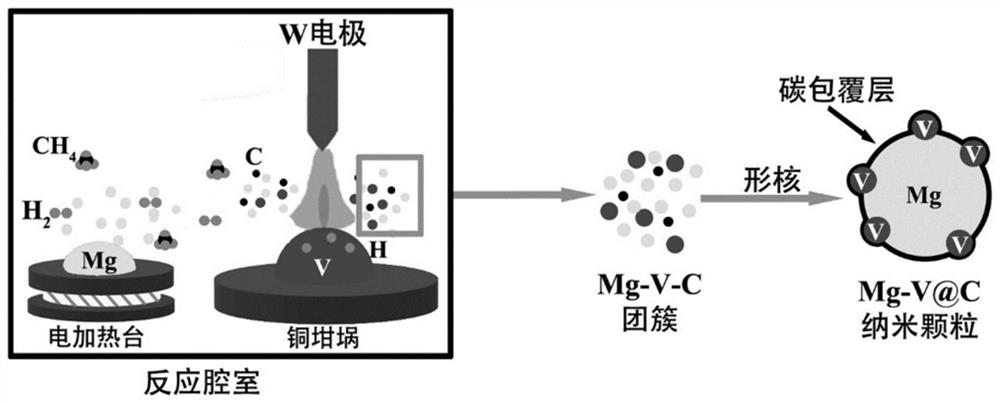

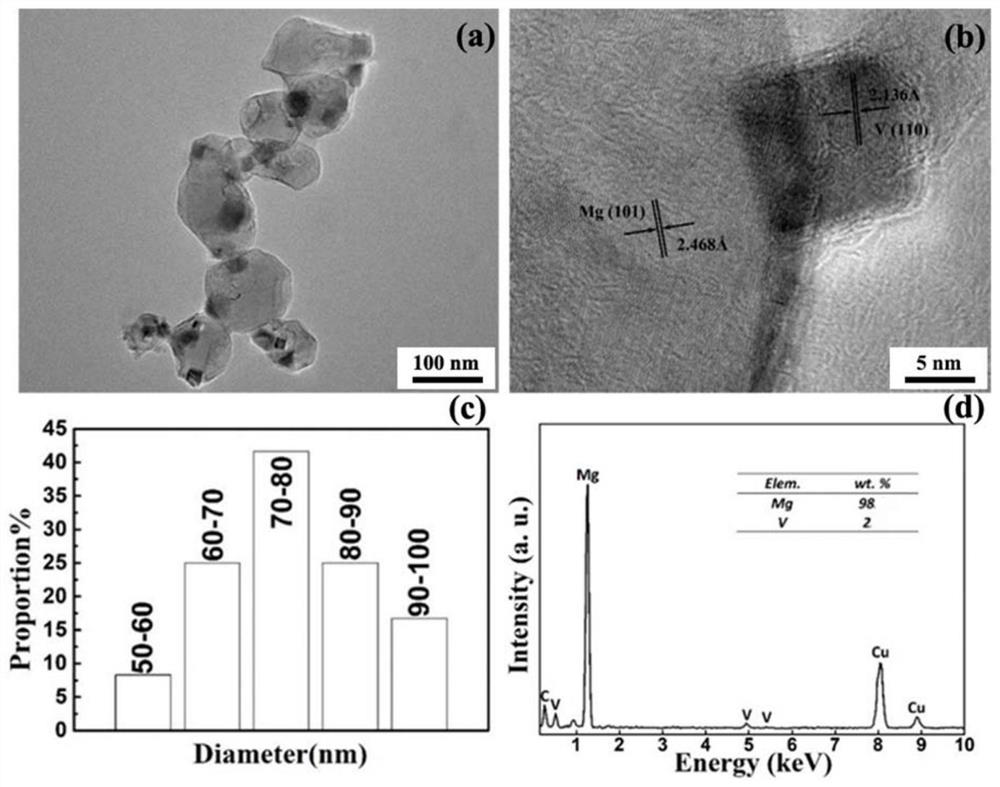

[0036] Example 1: Mg 98 V 2 Preparation of @C composite nanoparticles

[0037] (1) 15 grams of V metal ingots as catalysts are placed on the copper crucible of the plasma equipment reaction chamber, and 3 grams of Mg block is placed on the resistance heating table in the reaction chamber;

[0038] (2) close the reaction chamber, and evacuate the reaction chamber;

[0039] (3) Fill the reaction chamber with high-purity argon and high-purity hydrogen at a ratio of (hydrogen: argon = 1:3) until the total pressure of the chamber is 0.09MPa, and fill with 0.017vol% CH 4 gas;

[0040] (4) Turn on the power supply of the resistance heating table, control the surface temperature of the resistance heating table to be 550 ° C, and heat the Mg block through the resistance heating table; after the Mg starts to evaporate, start the plasma power supply, set the current to 60A, and heat the Mg block through the plasma arc. The metal V ingot as a catalyst is heated and evaporated. The V ...

Embodiment 2

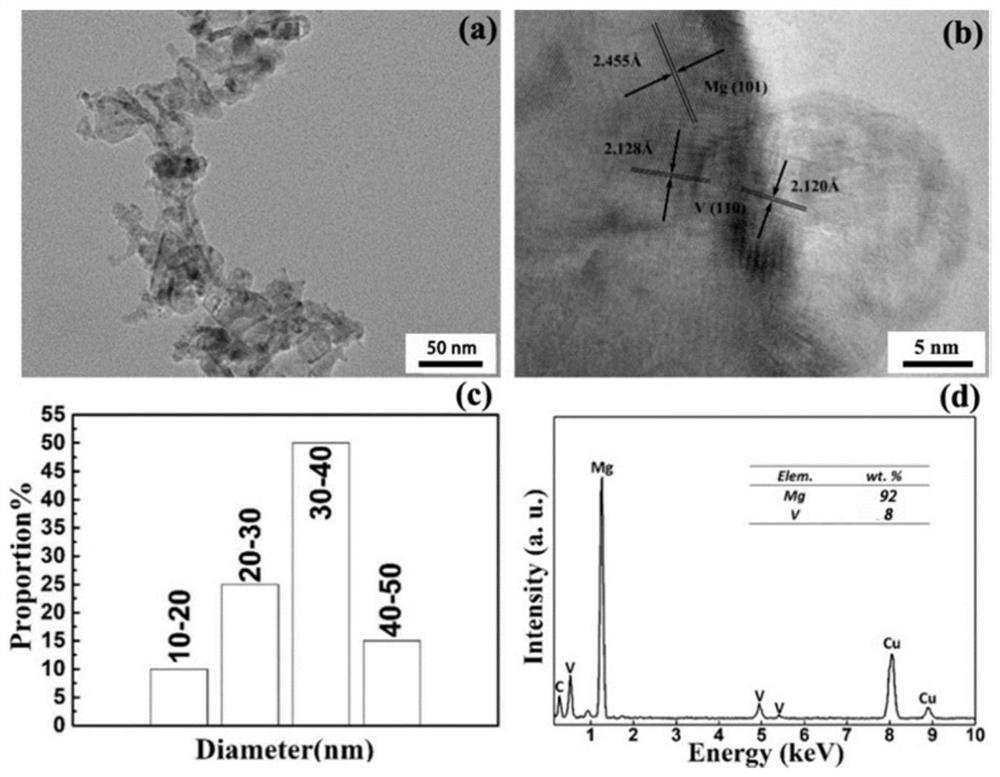

[0044] Example 2: Mg 92 V 8 Preparation of @C composite nanoparticles

[0045] (1) 15 grams of V metal ingots as catalysts are placed on the copper crucible of the plasma equipment reaction chamber, and 1.5 grams of Mg block is placed on the resistance heating table in the reaction chamber;

[0046] (2) close the reaction chamber, and evacuate the reaction chamber;

[0047] (3) Fill the reaction chamber with high-purity argon and high-purity hydrogen at a ratio of (hydrogen: argon = 1:3) until the total pressure of the chamber is 0.09MPa, and fill with 0.017vol% CH 4 gas;

[0048] (4) Turn on the power supply of the resistance heating table, control the surface temperature of the resistance heating table to be 550 ° C, and heat the Mg block through the resistance heating table; after the Mg starts to evaporate, start the plasma power supply, set the current to 60A, and heat the Mg block through the plasma arc. The metal V ingot as a catalyst is heated and evaporated. The ...

Embodiment 3

[0052] Example 3: Mg 75 V 25 Preparation of @C composite nanoparticles

[0053] (1) 15 grams of V metal ingots as catalysts are placed on the copper crucible of the plasma equipment reaction chamber, and 0.3 gram of Mg blocks are placed on the resistance heating table in the reaction chamber;

[0054] (2) close the reaction chamber, and evacuate the reaction chamber;

[0055] (3) Fill the reaction chamber with high-purity argon and high-purity hydrogen at a ratio of (hydrogen: argon = 1:3) until the total pressure of the chamber is 0.09MPa, and fill with 0.017vol% CH 4 gas;

[0056] (4) Turn on the power supply of the resistance heating table, control the surface temperature of the resistance heating table to be 550 ° C, and heat the Mg block through the resistance heating table; after the Mg starts to evaporate, start the plasma power supply, set the current to 60A, and heat the Mg block through the plasma arc. The metal V ingot as a catalyst is heated and evaporated. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com