[0002] With the rapid development of my country's economy and the expansion of the labor market, China has become the world's manufacturing kingdom, but the development of manufacturing has brought a lot of pollution. Among various pollution sources,

electroplating wastewater is especially difficult to treat due to its high

toxicity and large

discharge volume. It is worth noting that the electroplating industry is an important

processing industry in my country. It is widely used in machinery,

electronics and hardware industries. It is estimated that the total number of employees in the existing electroplating production plants in the country exceeds 500,000, with more than 5,000 production lines and the production capacity of electroplating area 250-300 million m2, the annual output value of the electroplating industry is about 10 billion yuan, the development of the electroplating industry makes the amount of corresponding

electroplating wastewater is also increasing, and the

electroplating wastewater contains

chromium,

nickel,

cadmium,

copper,

zinc, etc. Heavy

metal ions and

cyanide and other toxic substances, some of which are carcinogens, are extremely harmful to humans. Therefore, such waste water must be recycled to eliminate or reduce environmental pollution. According to the above statistics, it can be seen that the waste water of the electroplating industry in my country The annual

discharge is 1.995 billion / m3, how to deal with such a large amount of electroplating wastewater has become a problem

[0003] At present, the common electroplating wastewater treatment methods include chemical

precipitation method,

ion exchange method,

adsorption method, membrane

separation method and electrodialysis method. At present, the main problems faced by the electroplating industry wastewater treatment are concentrated in the low degree of specialization and low level of

mechanical equipment. The level of pollution control is low, the

effective treatment rate is low, the

operating cost is high, and the

wastewater reuse rate is low. Therefore, it is very important to find an economical and efficient method for treating electroplating wastewater. In the prior art, electrodialysis is generally used for electroplating wastewater treatment. The main method, the existing

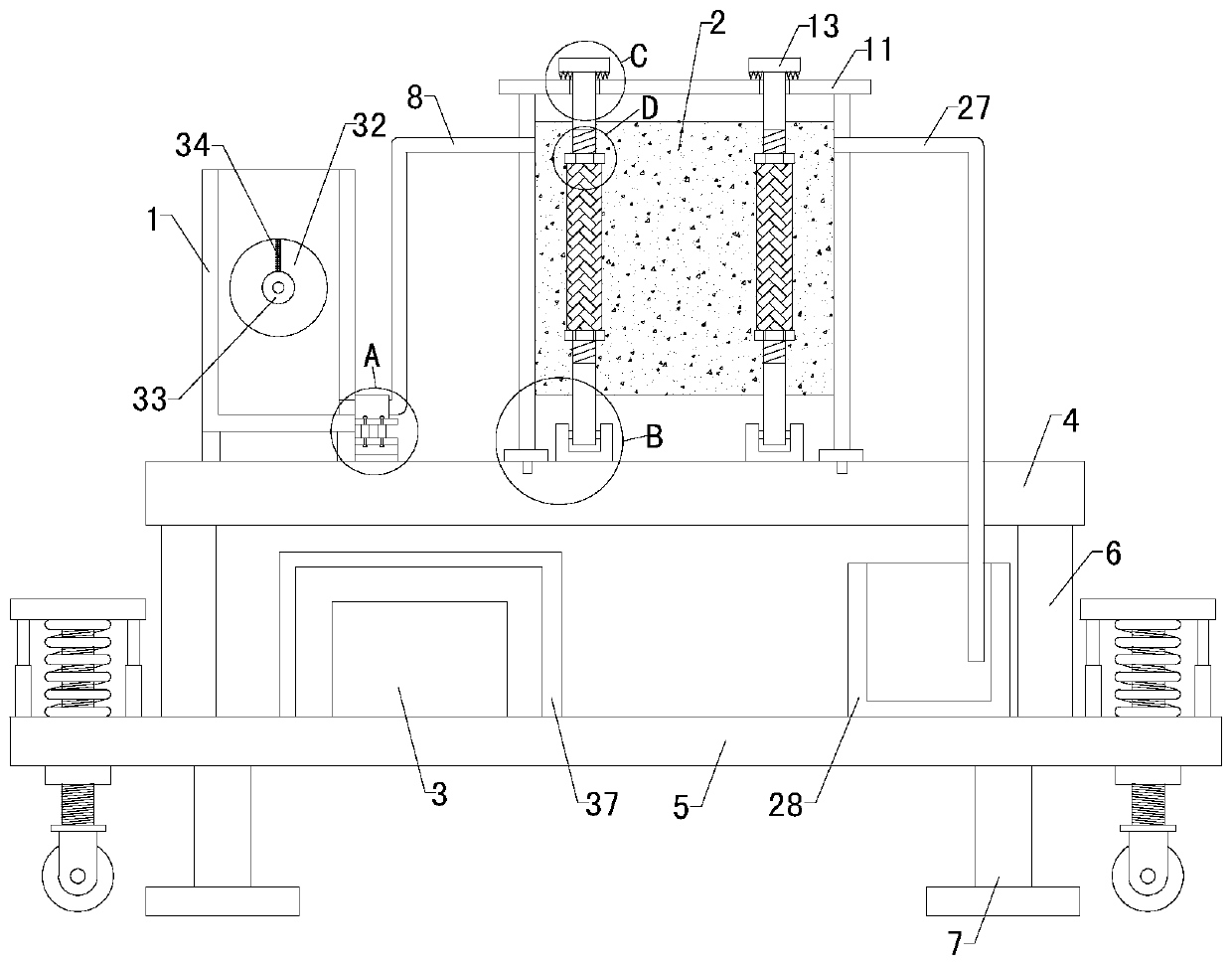

intelligent control electrodialysis treatment electroplating wastewater equipment includes waste

liquid tank, electrodialysis device,

PC controller and installation frame, installation frame includes top plate and bottom plate, and top is positioned at the top of bottom plate, the bottom of top plate and The top of the bottom plate is connected by two sets of support plates, the bottom of the bottom plate is provided with feet, the bottom of the waste

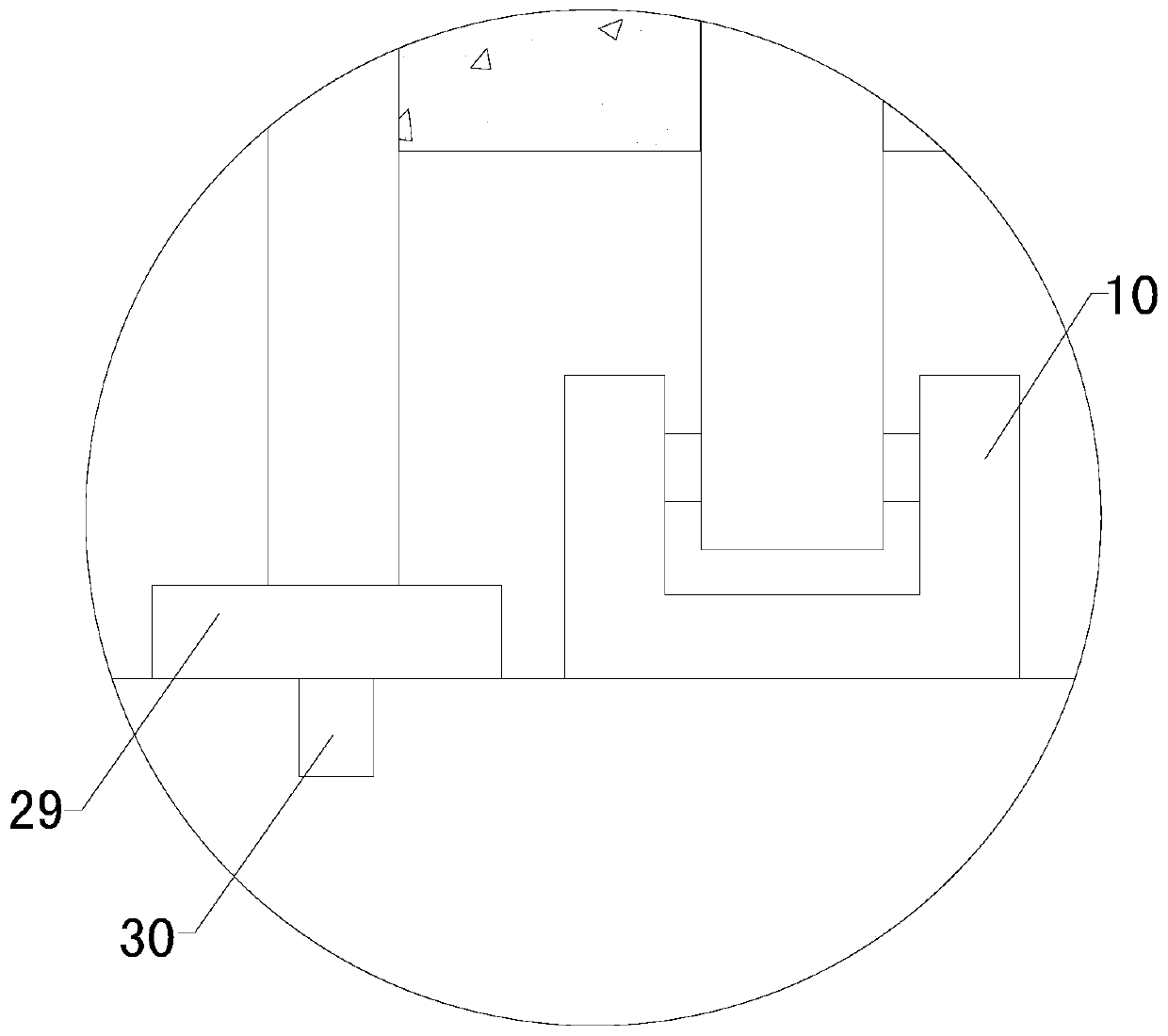

liquid tank is connected with the top left side of the top plate, and the electrodialysis device is installed on the top right side of the top plate, and the right end of the waste liquid tank is under the The side is connected with the left input end of the electrodialysis device through a connecting

pipe, and a water pump is arranged on the connecting

pipe, and the

PC controller is fixedly installed on the left side of the top of the bottom plate. The

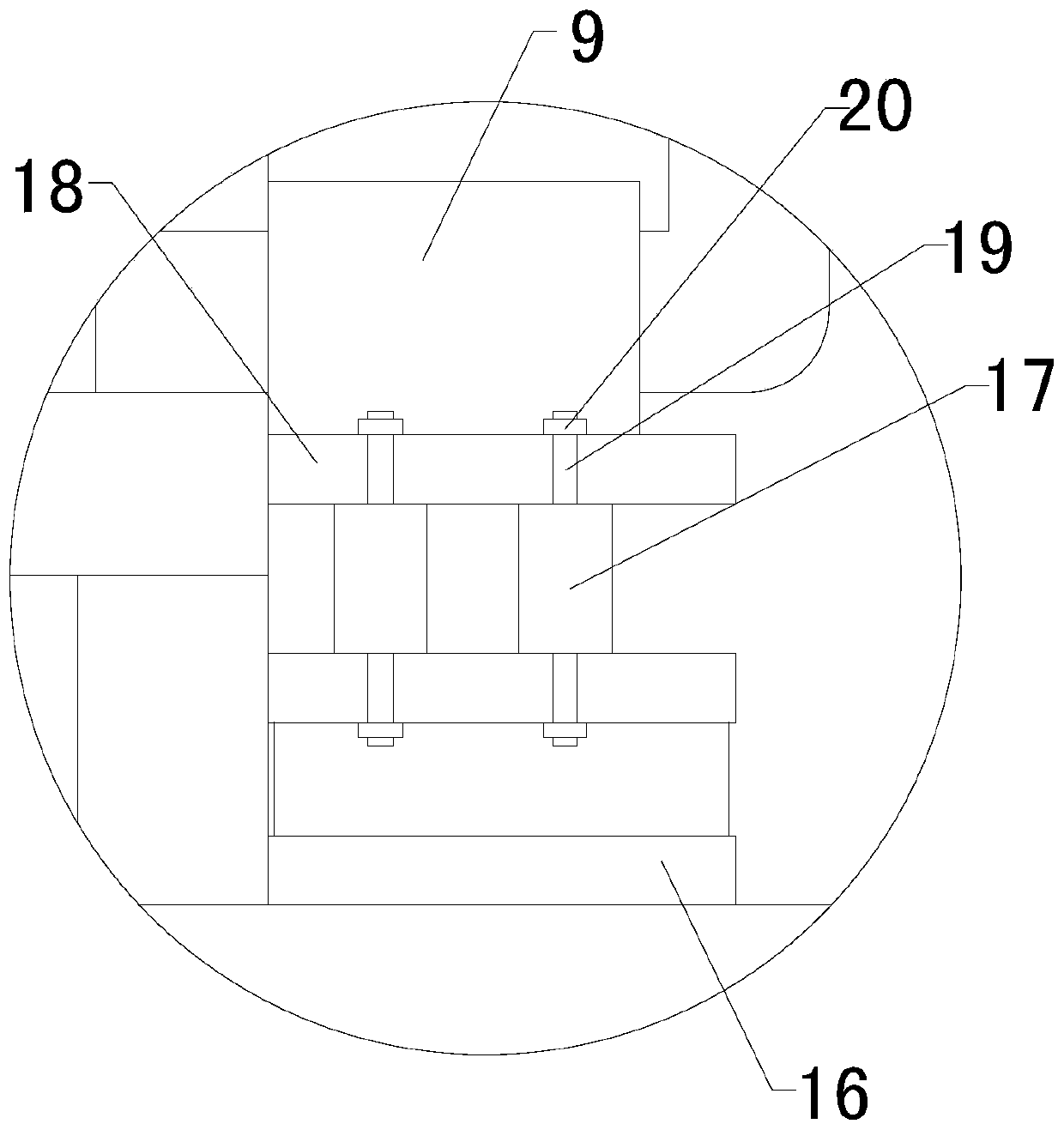

dialysis device is equipped with a

filter element group composed of a plurality of

filter element units. The front and rear ends of the

filter element unit are equipped with outer reinforcement plates, and the outer layer reinforcement plates are equipped with

graphite electrodes and sealing rings in turn. There are a plurality of anion exchange membranes and cation exchange membranes arranged alternately, and there are guide splint

layers on both sides of each anion exchange membrane and cation exchange membrane; when the existing

intelligent control electrodialysis treatment electroplating wastewater equipment is in use, the electroplating The waste water is sent to the inside of the waste liquid tank, and then the PC controller is powered on to control the operation of the water pump, and the waste liquid in the waste liquid tank is sent to the inside of the electrodialysis device, and the PC controller is used to control the operation of the electrodialysis device. For wastewater treatment, the selective permeability of the

ion exchange membrane in the electrodialysis device to the ions in the waste liquid is used to make the anions and cations in the waste liquid undergo

ion migration, and respectively pass through the anion and cation exchange membranes to purify the electroplating wastewater or concentrate The purpose of electrodialysis is enough; the existing

intelligent control electrodialysis treatment of electroplating wastewater equipment is found in

actual use, the inside of the electrodialysis device needs to be cleaned regularly, so that the electrodialysis can be better used. The electrodialysis device in the prior art and It is inconvenient to disassemble between the installation frames, which affects the efficiency of the internal cleaning operation of the electrodialysis device; at the same time, the water pump is prone to vibration during operation, and the overall shock absorption is poor, and there is a large

noise pollution in the operation of the equipment, which leads to its reliable use. and it is inconvenient to change the

location area of its operation and use, and its adaptability is poor, resulting in high limitations in its use

Login to View More

Login to View More  Login to View More

Login to View More