Method for purifying cobra venom and its products

A cobra venom and purification method technology, which is applied to the preparation method of peptides, chemical instruments and methods, medical preparations containing active ingredients, etc., can solve the problems of low product purity, complicated cobra venom purification process, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0204] Example 1: SPFF+MMC+low pressure inversion process

[0205] Step 1: Preprocessing

[0206] Get 20 grams of crude poison freeze-dried powder (Chinese cobra, Naja naja atra, purchased from Yiwu Chunfeng Snake Industry Co., Ltd.), its purity is 11.4% (measure with method 2, the result is as shown in table 1-1), add pH 800ml of 20mM PB buffer of 7.0, fully dissolved, centrifuged at 10000rpm for 20min at 4°C, and poured out the supernatant for later use.

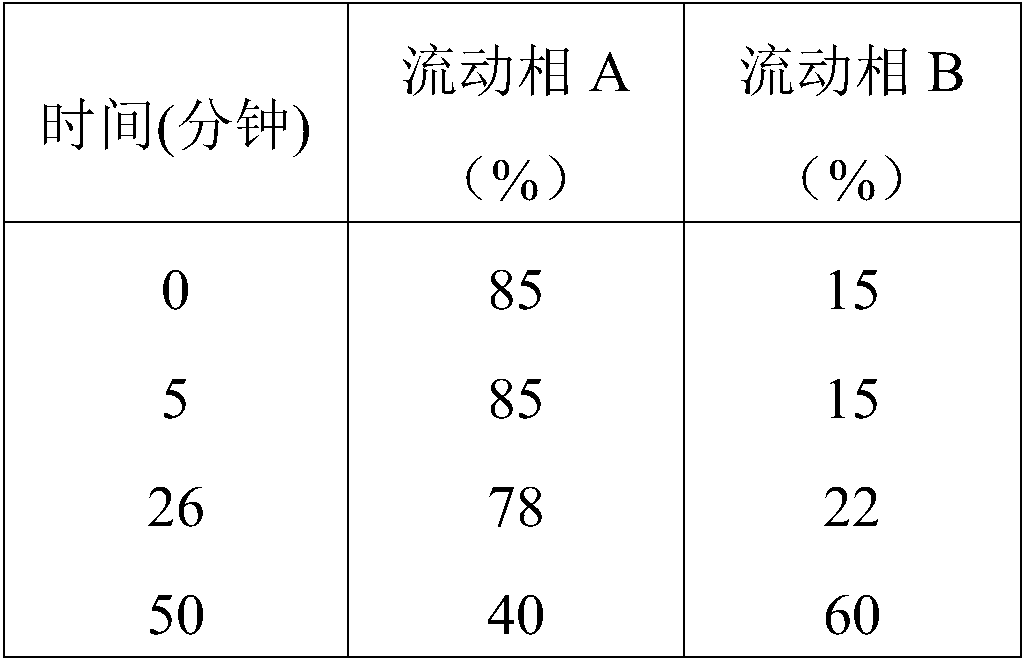

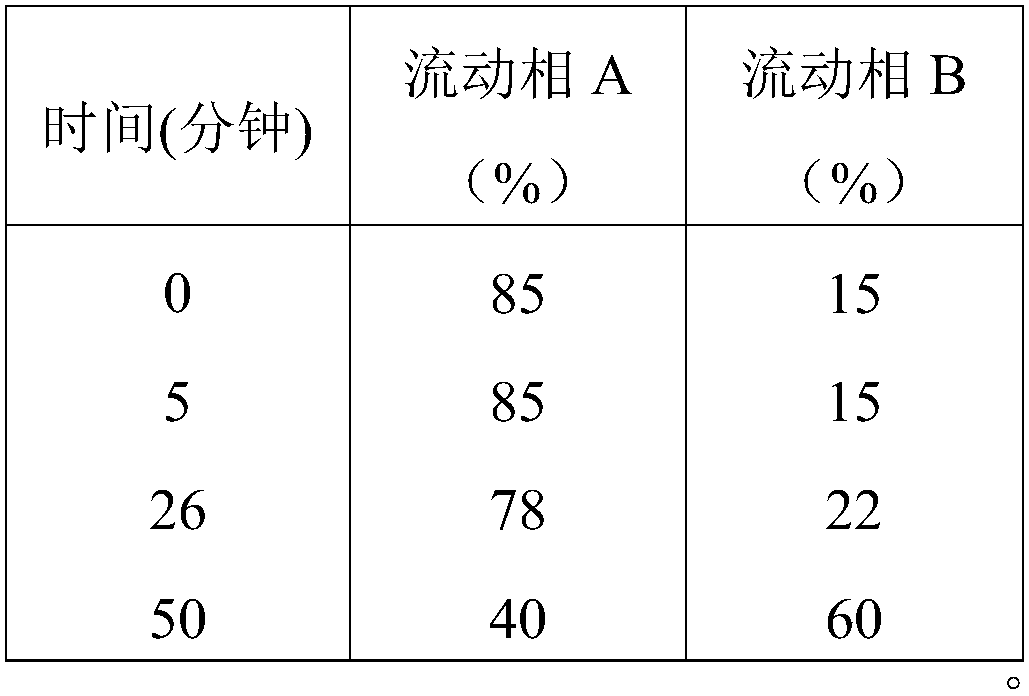

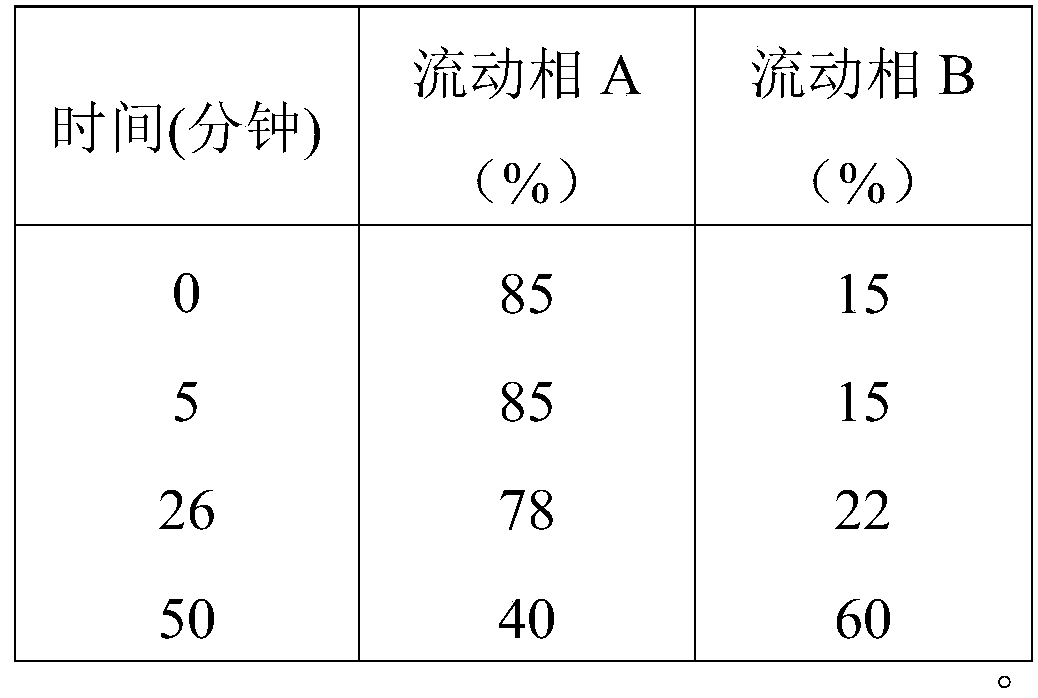

[0207] Table 1-1

[0208] Peak number

Impurity 2

cobra neurotoxin

Impurity 1

retention time / min

21.606

22.199

24.720

relative retention time

0.973

1.000

1.113

Peak width / min

0.2813

0.3053

0.2361

Peak area / mAU×s

131.02

1812.87

176.67

Peak height / mAU

7.27

92.63

10.84

Peak area percentage / %

0.83

11.43

1.11

[0209] Step 2: SPFF separation

[0210] SPFF column (self-packing column: Borgron empty column ...

Embodiment 2

[0224] Example 2: SPFF+MMC+Low Voltage Inversion Process 2

[0225] On the basis of Example 1, the reversed phase filler was changed to NMSIL 50-100C8 silica gel matrix, non-uniform particle size, average particle size 50μm, pore size The yield is 74.32% and the purity is 98.67% (measured by method 2, the results are shown in Table 2-1), and the identification data are basically the same as those in Example 1.

[0226] table 2-1

[0227] Peak number

Embodiment 3

[0228] Example 3: SPFF+MMC+low pressure reverse phase process 3

[0229] On the basis of Example 1, the reversed-phase filler was changed to UNIPS 40-300, phenyl matrix, uniform particle size, particle size 40 μm, pore size The yield is 95.71% and the purity is 98.22% (measured by method 2, the results are shown in Table 3-1), and the identification data are basically the same as those in Example 1.

[0230] Table 3-1

[0231] Peak number

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com