Fireproof flame-retardant anticorrosive coating material

A technology of anti-corrosion coatings and anti-corrosion materials, applied in the field of coatings, can solve the problems of poor adhesion, poor strength, and poor water resistance, and achieve the effects of strong adhesion, enhanced flame resistance, and good hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

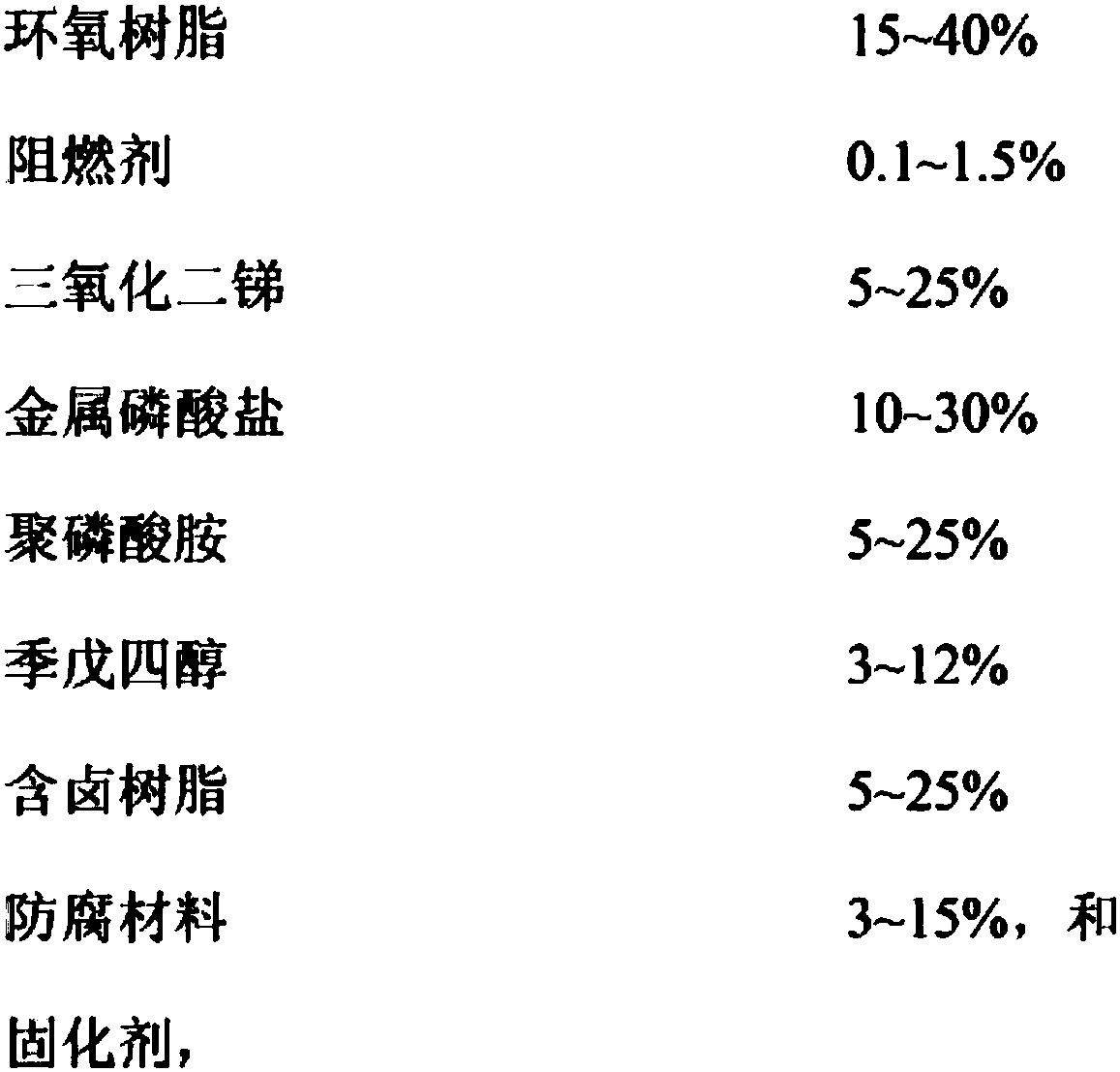

[0057] The present embodiment adopts following formula to prepare coating:

[0058] The main ingredient is composed of the following components according to the mass percentage:

[0059]

[0060] Wherein the mass ratio of the main agent to the cashew nut shell oil modified polyamide K54 is 3:1, and the anticorrosion material is a mixture of silica micropowder and micaceous iron oxide ash.

[0061] The preparation method is as follows: dispersion→sanding→paint mixing→inspection→filtering→packaging.

[0062] The paint was tested and the test results are shown in Table 1.

Embodiment 2

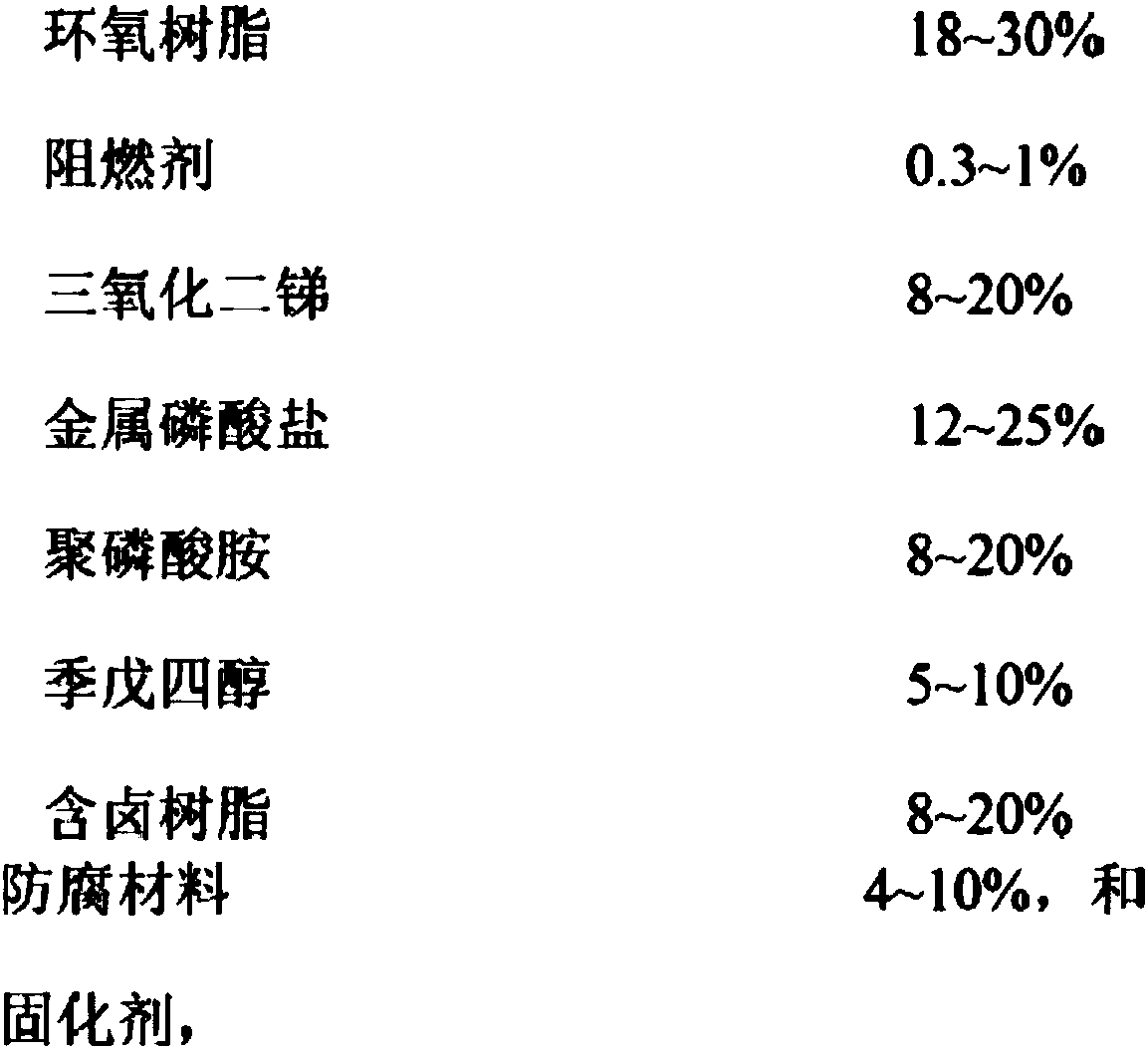

[0064] The present embodiment adopts following formula to prepare coating:

[0065] The main ingredient is composed of the following components according to the mass percentage:

[0066]

[0067] Wherein the mass ratio of the main agent to the cashew nut shell oil modified amine is 8:1, and the anti-corrosion material is silicon micropowder. The preparation method is as follows: dispersion→sanding→paint mixing→inspection→filtering→packaging.

[0068] The paint was tested and the test results are shown in Table 1.

Embodiment 3

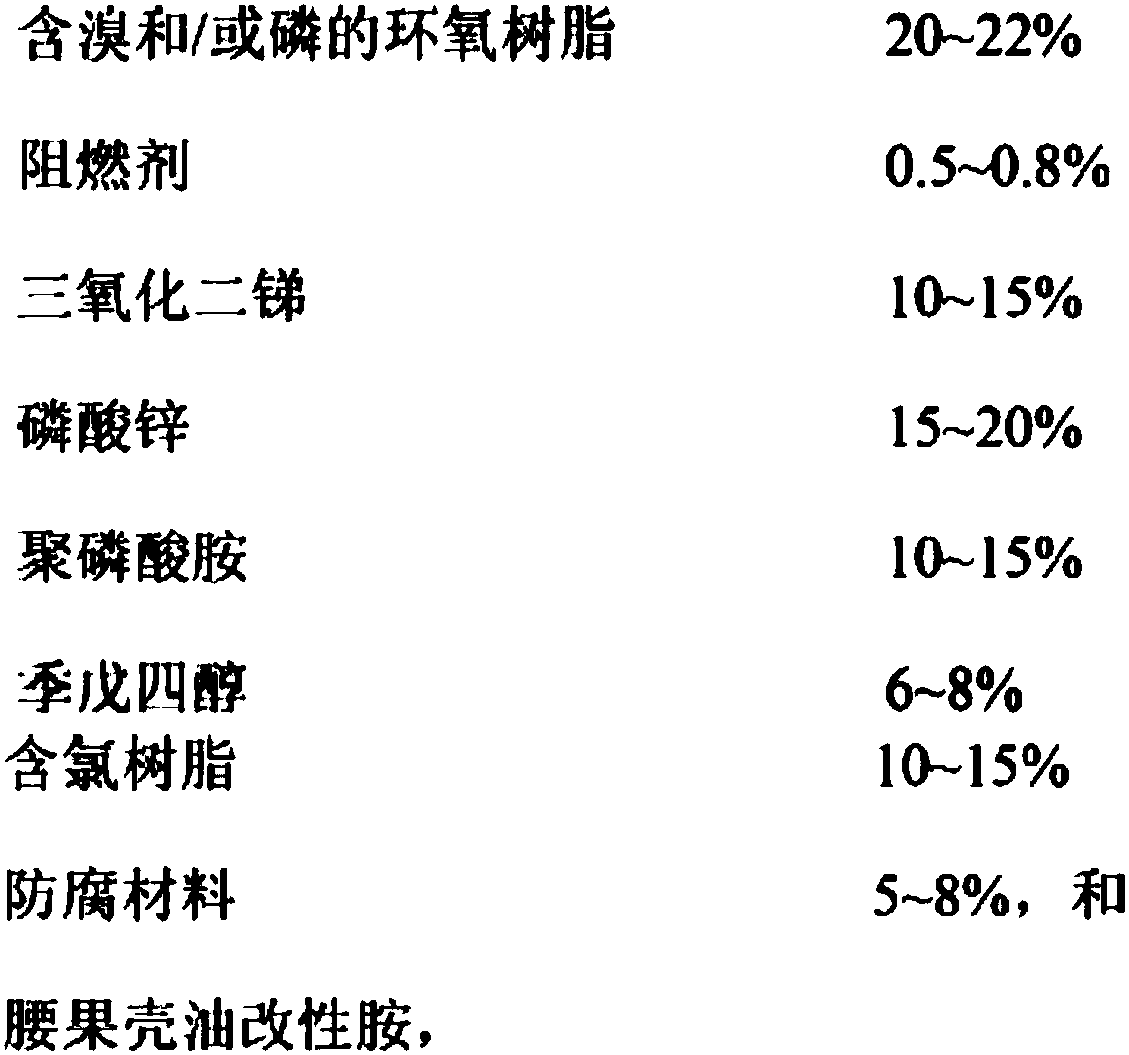

[0070] The present embodiment adopts following formula to prepare coating:

[0071] The main ingredient is composed of the following components according to the mass percentage:

[0072]

[0073] Wherein the mass ratio of the main agent to the cashew nut shell oil modified amine is 5:1, and the anticorrosion material is silicon micropowder and / or micaceous iron oxide ash.

[0074] The preparation method is as follows: dispersion→sanding→paint mixing→inspection→filtering→packaging.

[0075] The paint was tested and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com