A kind of α-β type high strength, high impact toughness titanium alloy and preparation method thereof

A technology of impact toughness and titanium alloy, applied in the field of titanium alloy, can solve the problems of high cost and small application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

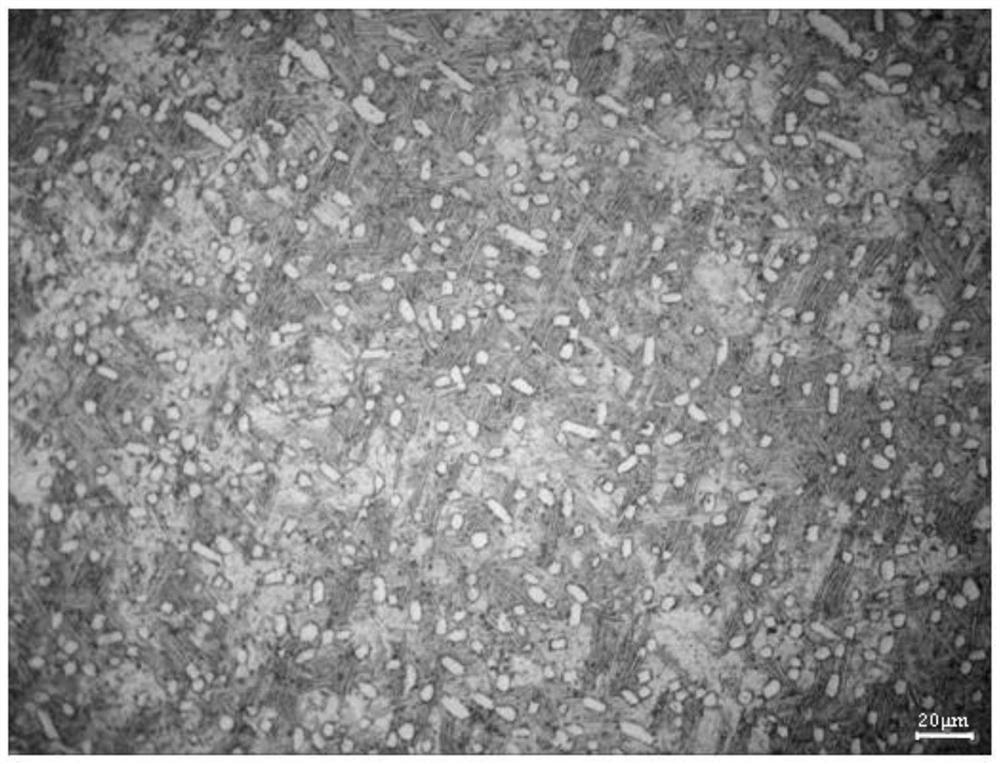

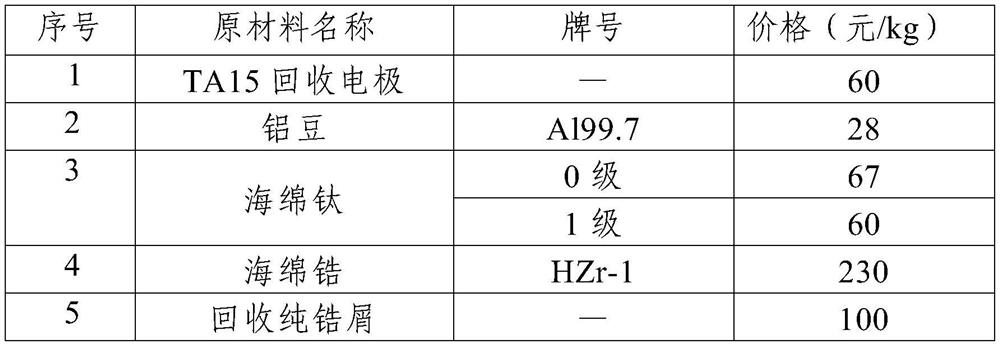

[0036] The α-β type high-strength, high-impact-toughness titanium alloy of this embodiment is composed of the following mass percentages: Al 5%, Zr 1.5%, Mo 0.8%, V 1%, Fe 2%, Cr 3%, and the balance is Ti and unavoidable impurities.

[0037] The preparation method of the α-β type high-strength, high-impact-toughness titanium alloy of this embodiment is as follows: the electrode prepared by TA15 reclaimed material is mixed with recycled pure zirconium shavings, iron-molybdenum master alloy, aluminum beans, iron nails, metal chromium, and titanium sponge The mixed and pressed electrodes are assembled and welded to prepare a smelting electrode, wherein the mass content of TA15 recycled material in the smelting electrode is 50%, and then smelted in a vacuum consumable electric arc furnace three times to obtain a titanium alloy ingot; the titanium alloy ingot is passed through After mechanical processing and subsequent thermal processing, a titanium alloy square rod with a side len...

Embodiment 2

[0041] The α-β type high-strength, high-impact-toughness titanium alloy of this embodiment is composed of the following mass percentages: Al 5.1%, Zr 1.8%, Mo 1.2%, V 1.6%, Fe 1.3%, Cr 2.0%, the balance For Ti and unavoidable impurities.

[0042] The preparation method of the α-β type high-strength, high-impact-toughness titanium alloy of this embodiment is as follows: the electrode prepared by TA15 reclaimed material is mixed with recycled pure zirconium shavings, iron-molybdenum master alloy, aluminum beans, iron nails, metal chromium, and titanium sponge The mixed and pressed electrodes are assembled and welded to prepare a smelting electrode, wherein the mass content of TA15 recycled material in the smelting electrode is 70%, and then smelted in a vacuum consumable electric arc furnace three times to obtain a titanium alloy ingot; the titanium alloy ingot is passed through After mechanical processing and subsequent thermal processing, a titanium alloy rod with a diameter o...

Embodiment 3

[0045] The α-β type high-strength, high-impact-toughness titanium alloy of this embodiment is composed of the following components by mass percentage: Al4.5%, Zr 2.5%, Mo 2.5%, V 0.8%, Fe 0.8%, Cr 3.0%, the balance For Ti and unavoidable impurities.

[0046] The preparation method of the α-β type high-strength, high-impact-toughness titanium alloy of this embodiment is as follows: the electrode prepared by TA15 reclaimed material is mixed with recycled pure zirconium shavings, iron-molybdenum master alloy, aluminum beans, iron nails, metal chromium, and titanium sponge The mixed and pressed electrodes are assembled and welded to prepare a smelting electrode, wherein the mass content of TA15 recycled material in the smelting electrode is 50%, and then smelted in a vacuum consumable electric arc furnace three times to obtain a titanium alloy ingot; the titanium alloy ingot is passed through After mechanical processing and subsequent thermal processing, a titanium alloy rod with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com