Carbon nanotube-doped composite electrode material and preparation method thereof

A technology of carbon nanotubes and composite electrodes, which is applied in the field of porous high specific capacitance composite electrode materials and its preparation, can solve problems such as difficulty in meeting energy needs, and achieve the effects of reducing industrial application costs, process stability, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

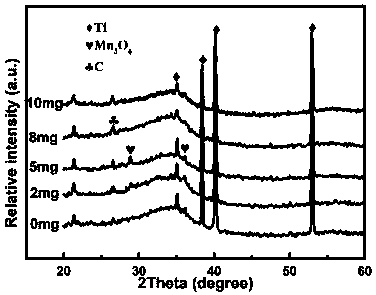

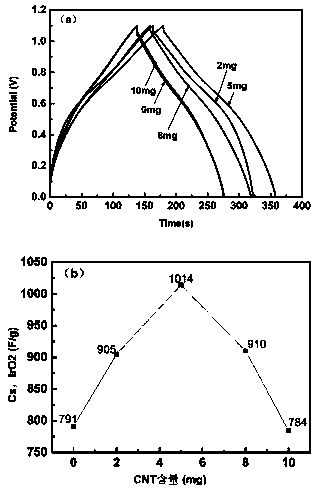

Embodiment 1

[0027] (1) Select industrial pure titanium plate TA 1 with a thickness of 1 mm as the base material, cut it with a wire cutting machine to obtain a titanium plate with a size of 10 mm × 10 mm × 1 mm, and engrave it in 0.2 ~ 0.8 mol / L concentrated sulfuric acid Corrosion for 1 h to 2 h, washed with water and dried, then placed in absolute ethanol for later use.

[0028] (2) Take chloroiridic acid (H 2 IrCl 6 ·6H 2 O containing iridium 35%) and manganese chloride (MnCl 2 ) was dissolved in absolute ethanol according to the molar ratio of Ir:Mn=4:6, the solution was ultrasonically oscillated for 30 min, and mixed evenly.

[0029] (3) Take 0 mg of carbon nanotubes and add 1 ml of H 2 IrCl 6 ·6H 2 O and MnCl 2 In the mixed solution, the above solution was ultrasonicated for 30 min to make a coating solution.

[0030] (4) Take an appropriate amount of coating solution to brush the titanium plate on one side. After the coating is uniform, dry the titanium plate under an infra...

Embodiment 2

[0032] (1) Select industrial pure titanium plate TA 1 with a thickness of 1 mm as the base material, cut it with a wire cutting machine to obtain a titanium plate with a size of 10mm × 10mm × 1 mm, and engrave it in 0.2 ~ 0.8 mol / L concentrated sulfuric acid Corrosion for 1 h to 2 h, washed with water and dried, then placed in absolute ethanol for later use.

[0033] (2) Take chloroiridic acid (H 2 IrCl 6 ·6H 2 O containing iridium 35%) and manganese chloride (MnCl2 ) was dissolved in absolute ethanol according to the molar ratio of Ir:Mn=4:6, the solution was ultrasonically oscillated for 30 min, and mixed evenly.

[0034] (3) Take 2 mg of carbon nanotubes and add 1 ml of H 2 IrCl 6 ·6H 2 O and MnCl 2 In the mixed solution, the above solution was ultrasonicated for 30 min to make a coating solution.

[0035] (4) Take an appropriate amount of coating solution to brush the titanium plate on one side. After the coating is uniform, dry the titanium plate under an infrared ...

Embodiment 3

[0037] (1) Select industrial pure titanium plate TA 1 with a thickness of 1 mm as the base material, cut it with a wire cutting machine to obtain a titanium plate with a size of 10 mm × 10 mm × 1 mm, and engrave it in 0.2 ~ 0.8 mol / L concentrated sulfuric acid Corrosion for 1 h to 2 h, washed with water and dried, then placed in absolute ethanol for later use.

[0038] (2) Take chloroiridic acid (H 2 IrCl 6 ·6H 2 O containing iridium 35%) and manganese chloride (MnCl 2 ) was dissolved in absolute ethanol according to the molar ratio of Ir:Mn=4:6, the solution was ultrasonically oscillated for 30 min, and mixed evenly.

[0039] (3) Take 5 mg of carbon nanotubes and add 1ml of H 2 IrCl 6 ·6H 2 O and MnCl 2 In the mixed solution, the above solution was ultrasonicated for 30 min to make a coating solution.

[0040] (4) Take an appropriate amount of coating solution to brush the titanium plate on one side. After the coating is uniform, dry the titanium plate under an infrar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com