Pt-Fe nano catalyst and preparation method and application thereof

A nano-catalyst, pt-fe technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of reducing the utilization rate of active metals, increasing material consumption, etc., and achieve high selectivity and high selectivity The effect of stable performance and catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

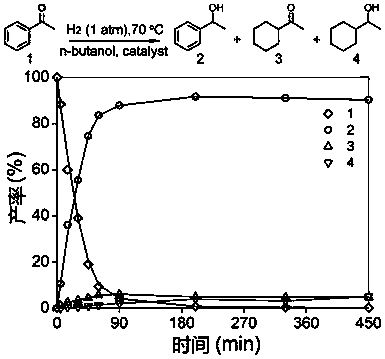

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of Pt-Fe nano catalyst, comprising:

[0027] A) prepare Pt-Fe nanowire; The preparation method of described Pt-Fe nanowire comprises:

[0028] Mix and heat platinum acetylacetonate, cetyltrimethylammonium chloride, dibenzyl ether and oleylamine, then mix and heat with dibenzyl ether solution of triiron dodecacarbonyl, cool, separate, wash and dry to obtain Pt- Fe nanowires;

[0029] B) Pt-Fe nanowires, solvent and activated carbon are mixed, stirred, centrifuged and washed to obtain a Pt-Fe nano catalyst loaded on the activated carbon.

[0030] The present invention first prepares Pt-Fe nanowires.

[0031] According to the present invention, the preparation method of the Pt-Fe nanowires comprises:

[0032] Platinum acetylacetonate, cetyltrimethylammonium chloride, dibenzyl ether and oleylamine are first mixed to obtain a homogeneous mixture.

[0033] Wherein, the weight-to-volume ratio of platinum acetylacetonate, ...

Embodiment 1

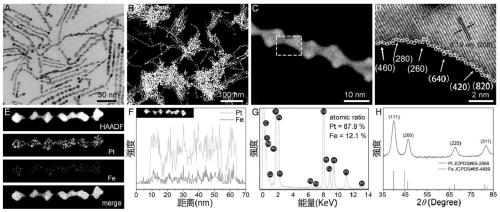

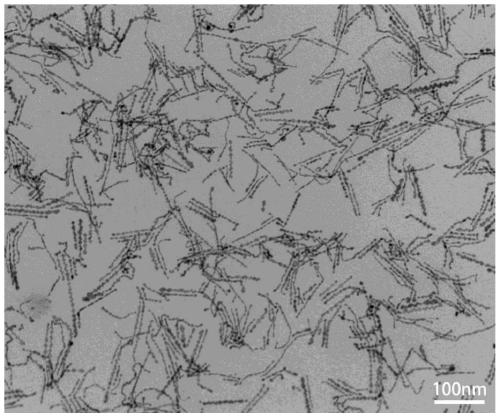

[0060] A Pt-Fe nano-catalyst, the catalyst includes Pt-Fe nano-wires with abundant high-index facets, loaded on activated carbon.

[0061] The preparation method of above-mentioned Pt-Fe nanometer catalyst comprises:

[0062] The obtained sample was purified by heating the Pt-Fe nanowires at 120° C. in air for 3 hours and keeping at 80° C. under vacuum for 3 hours. In a typical synthesis of Pt-Fe nanocrystals / C, the sample (20 mg) was dispersed in 10 mL of n-butanol in a 20 mL vial, followed by the addition of activated carbon (80 mg). The colloidal mixture was vigorously stirred for 4 hours, centrifuged at 11,000 rpm for 15 minutes to obtain a solid product, and then washed once with n-butanol.

[0063] The above-mentioned Pt-Fe nanowires are obtained by the following preparation method:

[0064] Will contain 11.8mg Pt(acac) 2 , a mixture of 288 mg CTAC, 1.5 mL BE and 2.5 mL OAm was charged into a 20 mL vial at room temperature. Transfer the solution to a 180 °C oil bath ...

Embodiment 2

[0069] A Pt-Fe nano-catalyst, the catalyst includes Pt-Fe nano-wires with abundant high-index faces, loaded on activated carbon.

[0070] The preparation method of above-mentioned Pt-Fe nanometer catalyst comprises:

[0071] The obtained sample was purified by heating the Pt-Fe nanowires at 120° C. in air for 3 hours and keeping at 80° C. under vacuum for 3 hours. In a typical synthesis of Pt-Fe nanocrystals / C, the sample (20 mg) was dispersed in 10 mL of n-butanol in a 20 mL vial, followed by the addition of activated carbon (80 mg). The colloidal mixture was vigorously stirred for 4 hours, centrifuged at 11,000 rpm for 15 minutes to obtain a solid product, and then washed once with n-butanol.

[0072] The above-mentioned Pt-Fe nanowires are obtained by the following preparation method:

[0073] Will contain 11.8mg Pt(acac) 2 , a mixture of 288 mg CTAC, 1.5 mL BE and 2.5 mL OAm was charged into a 20 mL vial at room temperature. Transfer the solution to a 180 °C oil bath f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com