Continuous flow rising type aerobic granular sludge reactor

An aerobic granular sludge and reactor technology, which is applied in the fields of environmental engineering and water treatment engineering, can solve problems such as long startup time, and achieve the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

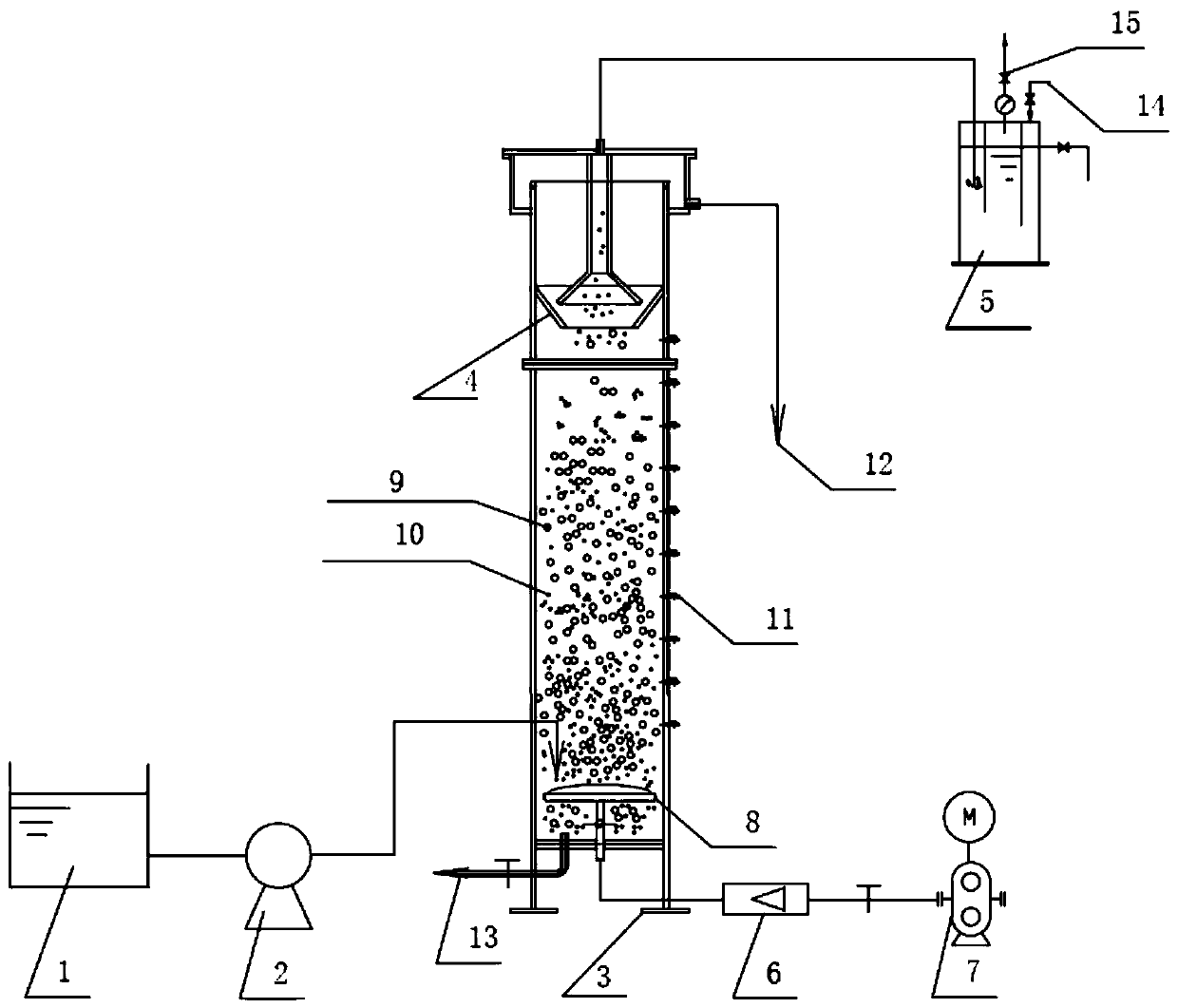

[0038] Such as figure 1 As shown, a continuous flow upflow aerobic granular sludge reactor, including: water tank 1, peristaltic pump 2, AGSB device 3, three-phase separator 4, pressure control water seal tank 5, gas flow meter 6, blower 7. Aeration pan 8, aerobic granular sludge 9, air bubbles 10, sampling port 11, water outlet 12, mud discharge pipe 13, tap water inlet valve 14, exhaust valve 15, the water tank 1 passes through the peristaltic pump 2 Connect the AGSB device 3, the AGSB device 3 is provided with aerobic granular sludge 9, and the bottom is provided with an aeration pan 8; the blower 7 is connected to the aeration pan 8 through a pipeline, and a gas flow meter 6 is arranged on the pipeline , the three-phase separator 4 is arranged on the top of the AGSB device 3, the three-phase separator 4 is provided with a liquid phase zone, a gas phase zone and a solid phase zone, wherein the solid phase zone is connected to the AGSB device 3, and the liquid phase zone is ...

Embodiment 2

[0046] Adopt same reactor as embodiment 1, process COD be the industrial sewage of 2600mg / L, this reactor operation method and main control parameter are as follows:

[0047] (1) The height-to-diameter ratio of the main body of AGSB device 3 is 7, and the COD concentration of the treated sewage influent is lower than 3000mg / L, higher than 2000mg / L, and the outlet water can be circulated into the water tank 1, and mixed with raw water 1:1 after dilution Use this device for processing. The water temperature is room temperature and does not need to be adjusted. The inoculum sludge is aerobic granular sludge with a particle size of 0.5-2.5mm.

[0048] (2) The three-phase separator 4 is connected with a pressure-controlling water-seal tank 5 to control the pressure in the air chamber of the three-phase separator 4, so that the three-phase separator has the highest processing efficiency, the suspended matter in the effluent is reduced, and the reactor does not need to install a sec...

Embodiment 3

[0052] Adopt as embodiment 1 reactor, process COD be a certain industrial sewage of 3500mg / L, this device operating method and main control parameter are as follows:

[0053] (1) The aspect ratio of the main body of AGSB unit 3 is 8, the influent COD concentration is higher than 3000mg / L, first connected to the upflow anaerobic sludge bed reactor (UASB) for pretreatment, and the effluent COD concentration is about 1500mg / L , less than 2000mg / L, it can be directly pumped into the aerobic granular sludge reactor by peristaltic pump 2 for treatment. The water temperature is room temperature and does not need to be adjusted. The inoculum sludge is aerobic granular sludge with a particle size of 1-3mm.

[0054] (2) The three-phase separator 4 is connected with a pressure-controlling water-seal tank 5 to control the pressure in the air chamber of the three-phase separator 4, so that the three-phase separator has the highest processing efficiency, the suspended matter in the effluen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com