Covalent bonding PET based nanometer silver wire and graphene combined transparent flexible conductive film and preparation method thereof

A technology of graphene composite and nano-silver wire, which is applied to the conductive layer on the insulating carrier, nanotechnology for materials and surface science, nanotechnology, etc., can solve the new conductive film fog of nano-silver wire that is not resistant to bending Problems such as high temperature, silver migration during UV, large square resistance, etc., to achieve excellent adhesion, improve adhesion, and prevent migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

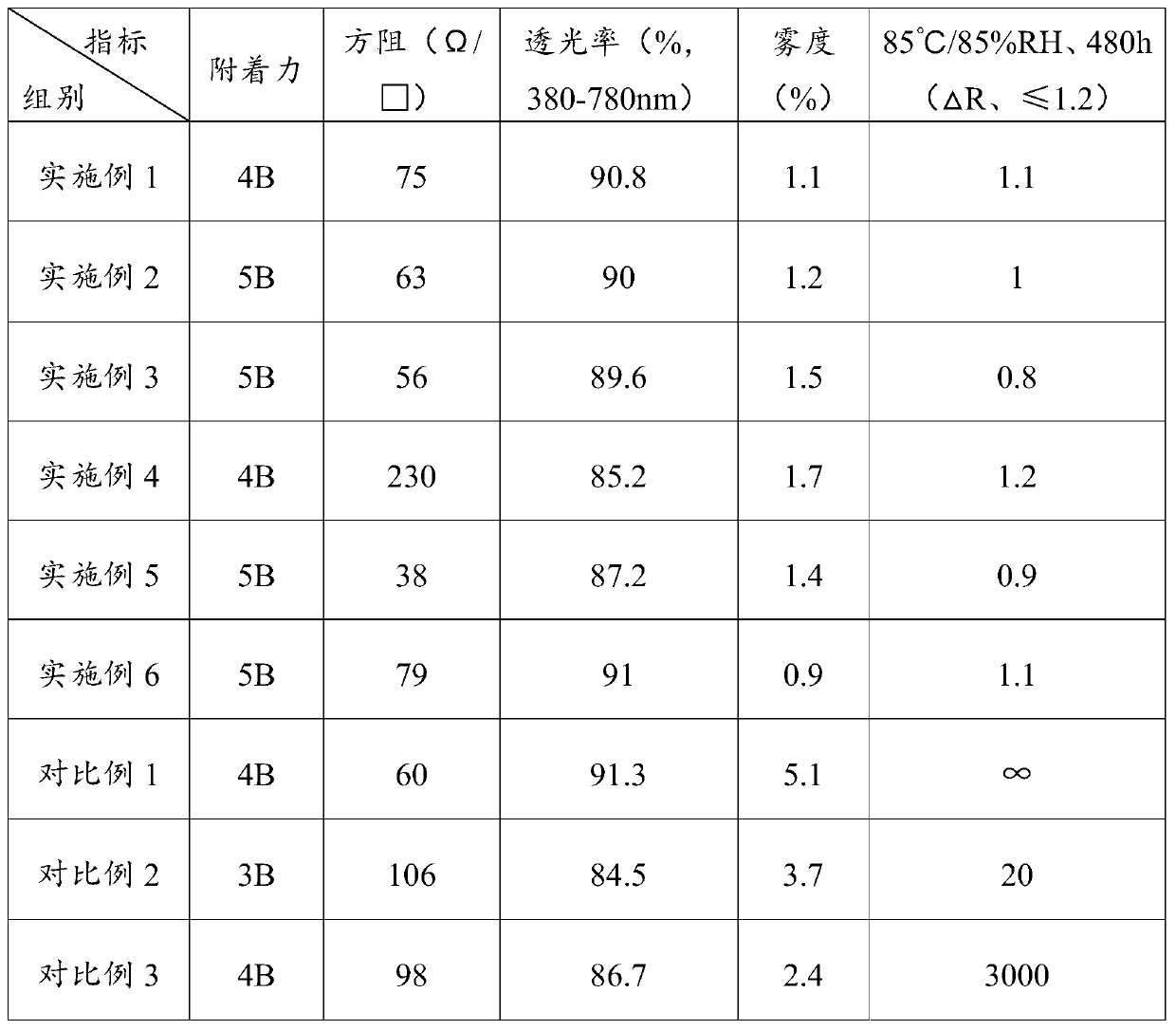

Examples

Embodiment 1

[0040] An embodiment of the covalently bonded PET-based nano-silver wire graphene composite transparent flexible conductive film of the present invention, the preparation method of the covalently bonded PET-based nano-silver wire graphene composite transparent flexible conductive film comprises The following steps:

[0041](1) Preparation of nano-silver wire water-based coating solution: select nano-silver wire with an aspect ratio of 800 and disperse it in the water-based hydroxyethyl acrylate monomer, and after mechanical stirring at room temperature for 30 minutes, configure it into a uniform dispersion with a solid content of 0.5% Nano-silver wire water-based hydroxyethyl acrylate coating liquid, and loaded into the micro-gravure coating head;

[0042] (2), preparation of modified graphene ethanol solution: after the 2-layer graphene is acidified and activated with nitric acid, then the graphene with active groups such as hydroxyl and carboxyl on the surface is dispersed i...

Embodiment 2

[0046] An embodiment of the covalently bonded PET-based nano-silver wire graphene composite transparent flexible conductive film of the present invention, the preparation method of the covalently bonded PET-based nano-silver wire graphene composite transparent flexible conductive film comprises The following steps:

[0047] (1) Preparation of nano-silver wire water-based coating solution: select nano-silver wire with an aspect ratio of 800 and disperse it in water-based hydroxyethyl acrylate monomer, and after mechanical stirring at room temperature for 45 minutes, configure it into a uniformly dispersed coating with a solid content of 1%. Nano-silver wire water-based hydroxyethyl acrylate coating liquid, and loaded into the micro-gravure coating head;

[0048] (2), preparation of modified graphene ethanol solution: after the 2-layer graphene is acidified and activated with nitric acid, then the graphene with active groups such as hydroxyl and carboxyl on the surface is disper...

Embodiment 3

[0052] An embodiment of the covalently bonded PET-based nano-silver wire graphene composite transparent flexible conductive film of the present invention, the preparation method of the covalently bonded PET-based nano-silver wire graphene composite transparent flexible conductive film comprises The following steps:

[0053] (1) Preparation of nano-silver wire water-based coating solution: select nano-silver wires with an aspect ratio of 800 and disperse them in water-based acrylic monomers, and after mechanical stirring at room temperature for 60 minutes, configure them into uniformly dispersed nano-silver wires with a solid content of 2% Water-based acrylic coating solution, and loaded into the micro gravure coating head;

[0054] (2), preparation of modified graphene ethanol solution: first use nitric acid and sulfuric acid mixed strong acid to acidify and activate the 2-layer graphene, and then disperse the graphene with active groups such as hydroxyl and carboxyl on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dry film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com