Defogging water-collecting device used for wet cooling tower

A technology of wet cooling and water collection device, which is applied in the direction of combined device, dispersed particle separation, chemical instruments and methods, etc., which can solve the problems of affecting the ventilation in the tower, the environmental factors of the cooling tower are greatly affected, and the installation is complicated, so as to relieve the liquid level Disturbing conditions, avoiding smog and icing, and reducing the effect of spreading and multiplying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

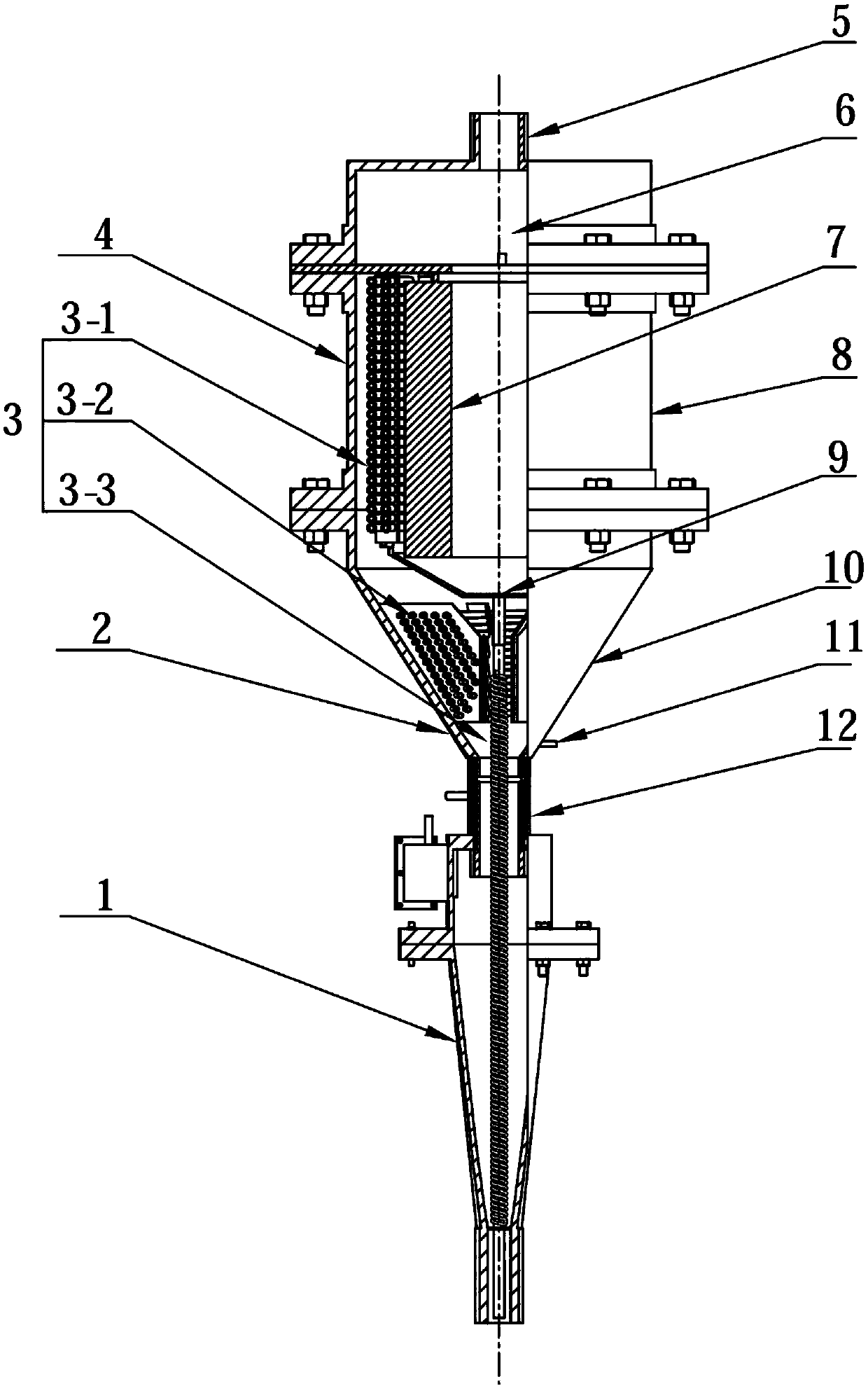

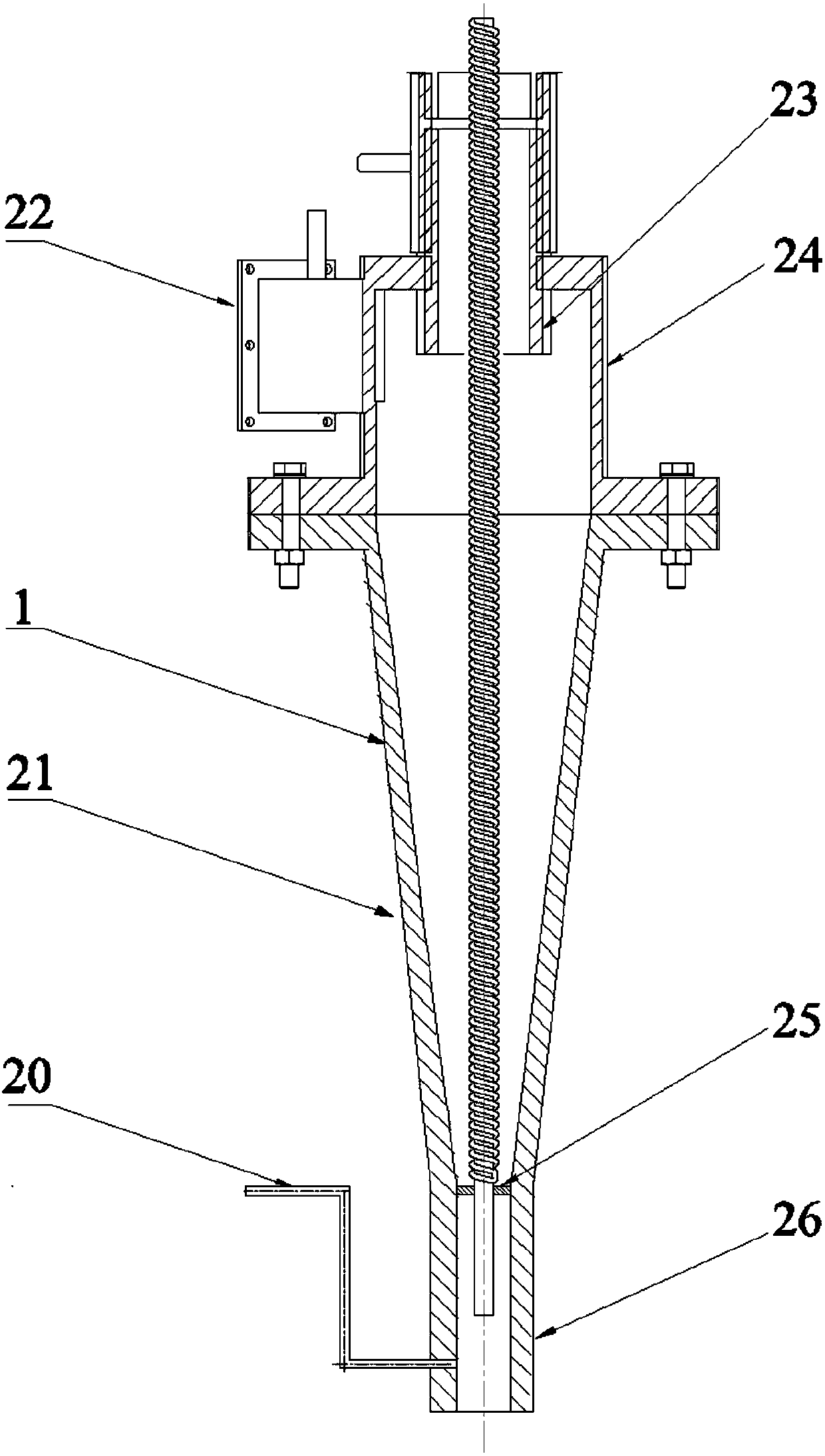

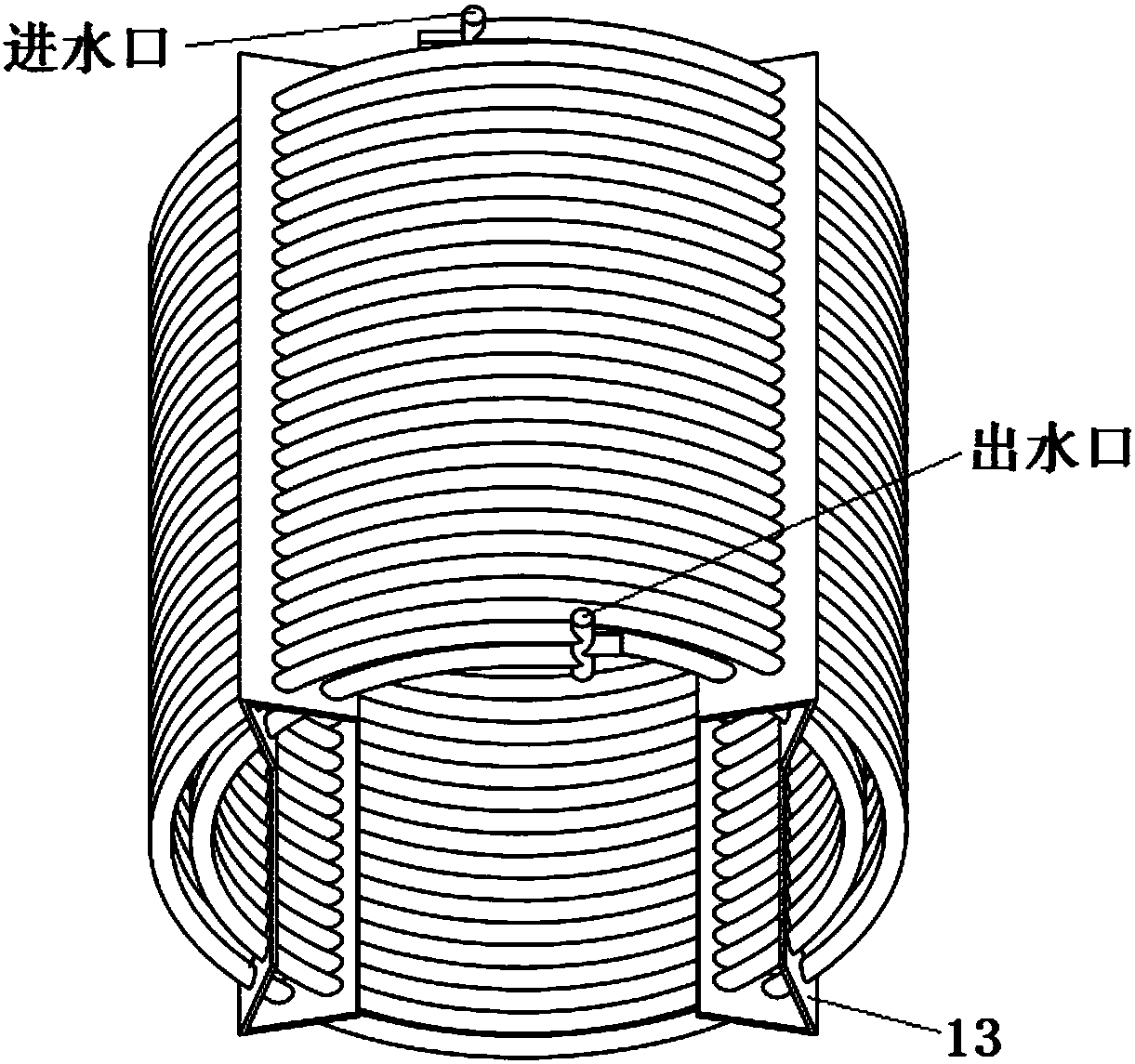

[0056] A central coil 3-3 is installed inside the device, and the fiber coalescer is subjected to PDMS-SiO 2 Superhydrophobic modification, to figure 1 The device shown is fed with supersaturated hot and humid gas entraining liquid droplets, and the hot and humid gas enters the device at a speed of 11m / s, and the content of liquid water droplets in the hot and humid gas is from 3.5g / m 3 Change to 12.5g / m 3 , after the device collects water stably for half an hour, collect the water recovered by the device within 10 minutes from the drain pipe 20 of the underflow pipe 26 and the outlet 11 of the transition unit 2 and weigh its quality. In order to reduce the experimental error, multiple times were used in the experiment By weighing and calculating the average value, the water recovery efficiency of the device is about 5%-6% higher than that of the central coil 3-3 under the same conditions.

Embodiment 2

[0058] A central coil 3-3 is installed inside the device, and the fiber coalescer is subjected to PDMS-SiO 2 Superhydrophobic modification, to figure 1 In the device shown, the supersaturated hot and humid gas with entraining liquid droplets is introduced. When the liquid concentration of the hot and humid gas is from 3.5g / m 3 Change to 12.5g / m 3 When the hot and humid gas enters the device at 11m / s, the water recovery efficiency of the device is lower than that of PDMS-SiO 2 Improve about 6%-6.5%.

Embodiment 3

[0060] A central coil 3-3 is installed inside the device, and the fiber coalescer is subjected to PDMS-SiO 2 Superhydrophobic modification, to figure 1 The device shown is fed with supersaturated hot and humid gas with entrained liquid droplets, when the liquid concentration in the hot and humid gas is 10.5g / m 3 , Cooling water flow rate and temperature are 65L / h and 10°C respectively, hot and humid gas enters the device at 11m / s, and the water recovery rate of the device can reach 87.41%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com