IGBT single-tube inversion manual arc welding machine and circuit structure thereof

A manual arc welding and circuit structure technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of limited application scope of welding machines, reduced reliability of welding machines, and poor ability to resist network voltage fluctuations. Realize the effect of power supply overvoltage protection control, improve the ability to resist network voltage fluctuations, and reduce the number of production and processing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

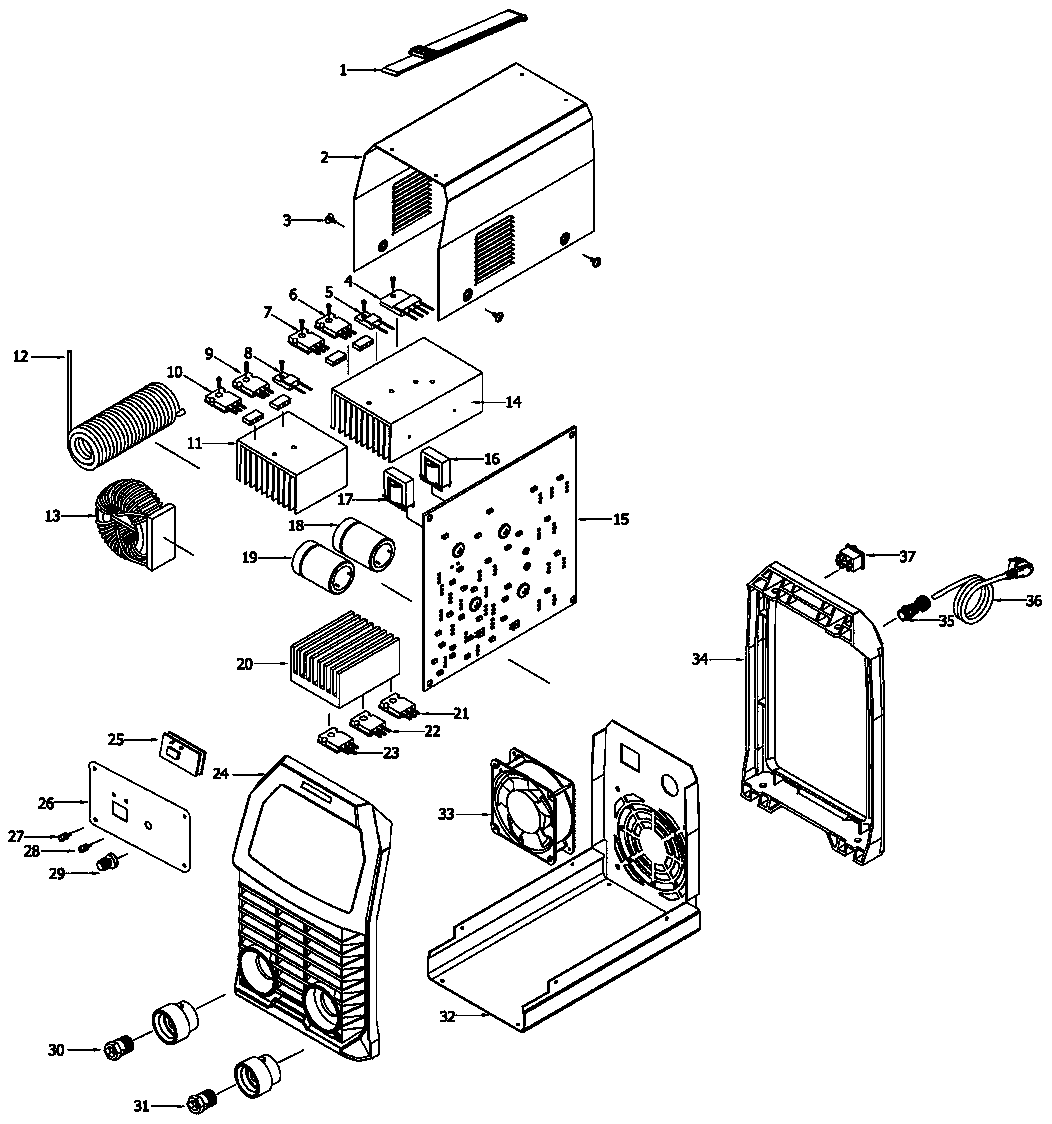

[0024] Such as figure 1 Shown is a schematic diagram of the structural design of the IGBT inverter welding machine made by the present invention, and its main components include: the front panel part. Mainly include the positive output quick connector and connector seat assembly 30, the negative output quick connector and connector seat assembly 31, the front plastic mask 24, the digital display meter and the working power white indicator light 27 on the front control panel 25, and the thermal protection yellow indicator light 28. Current adjustment potentiometer and knob 29, etc.

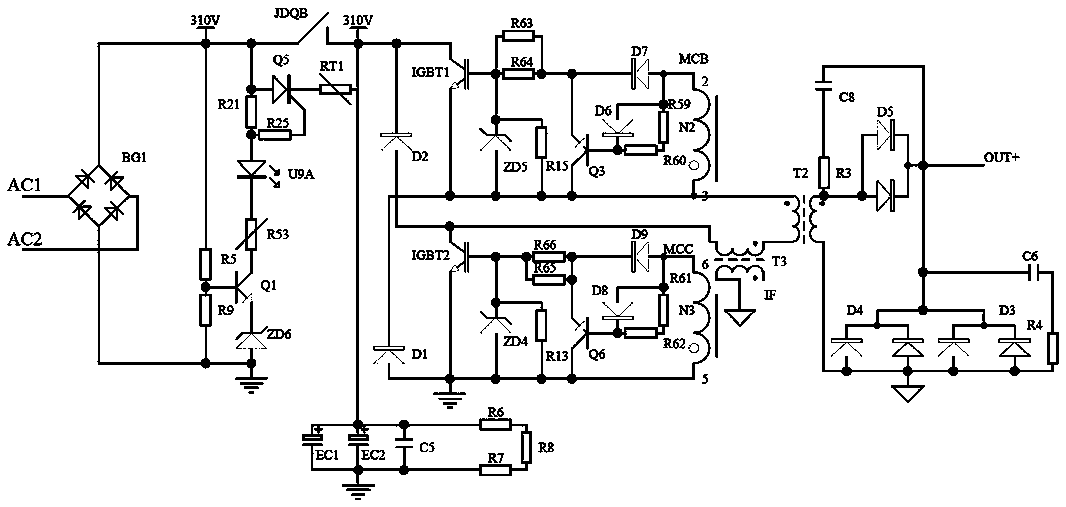

[0025] There is a current display meter on the front circuit board assembly, as well as power supply and overheat protection indicator light-emitting diodes, and many other electronic components. Its circuit board is called the control board. The control board has output current adjustment potentiometer, UC3846PWM control chip, operational amplifier LM324 chip, and many other electronic component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com