A method for preparing high-purity cerium aluminate by high-temperature buried carbon method

A high-purity, cerium aluminate technology, applied in the field of material synthesis, can solve the problems of unsuitable industrial preparation process, low utilization efficiency of reducing gas, long reduction time, etc. Effect of Purity Guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

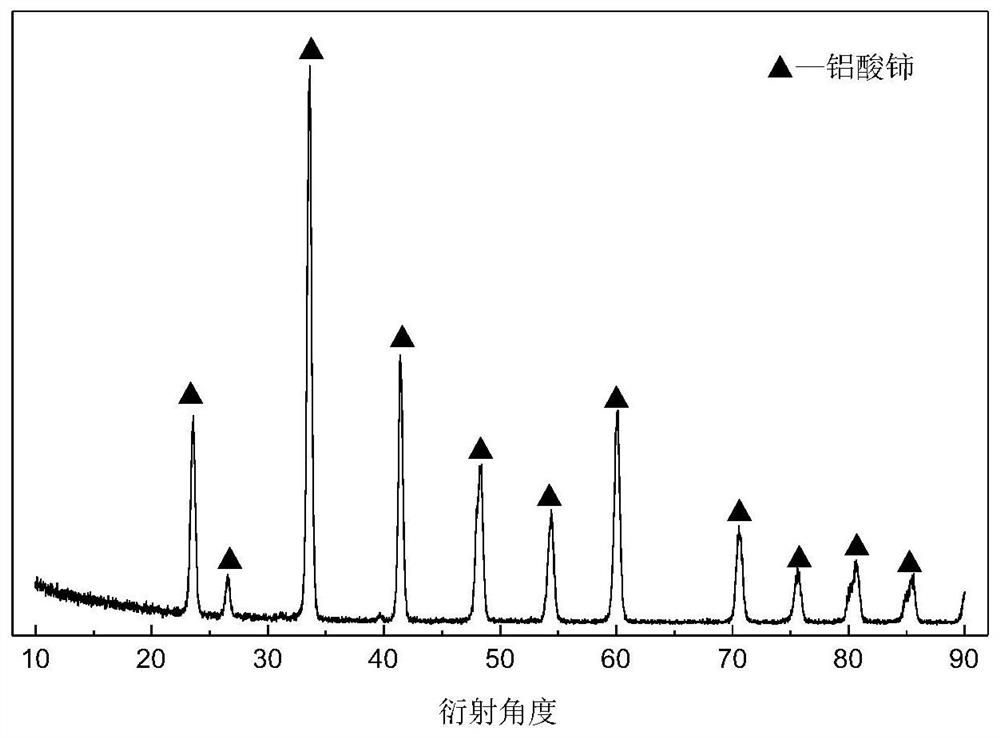

Image

Examples

Embodiment 1

[0026] The experimental raw materials selected in this example are analytically pure cerium oxide, industrial alumina powder and graphite powder, and the proportioning ratio is 172.11:50.94:6 by weight. Afterwards, the mixed material is crushed and mixed in a ball mill to a uniform material within 200 mesh. Afterwards, press equipment such as a hydraulic press to press the mixture into a green compact with a diameter of 2 cm and a thickness of 1.5 cm under a pressing force of 120 KN. Then place the raw material of the green body in the center of the corundum crucible filled with graphite, and after ensuring that the graphite is relatively compact, place a corundum cover plate on the top of the crucible to prevent excessive graphite from oxidizing during the heating process. Put it into the heating furnace at hand for high-temperature roasting and reduction. The reduction temperature is controlled at 1500° C., and the reduction reaction time is 4 hours. After the material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com