Water-based glue hardener and preparation method thereof

A hardener and water-based glue technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of wetting agent detachment, poor storage stability of hardener, and unstable adhesion and other problems, to achieve the effect of stable adhesion, good wettability and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

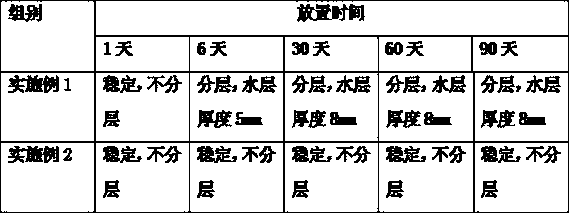

Embodiment 1

[0027] A water-based glue hardener, including 10% sulfur, 13% accelerator, 5% wetting and dispersing agent, 4% thickener, 66% deionized water, 1.39% defoamer, 0.61% bactericide, The wetting and dispersing agent includes polyimide, a solvation chain and an anchoring group, wherein the anchoring group is formed by grafting a solvation chain on polyimide and then reacting with phosphoric acid ester or acid anhydride.

[0028] The thickener is methyl cellulose,

[0029] The defoamer is polydimethylsiloxane,

[0030] Described bactericide is the PreventolP91 of Germany Lanxess Company,

[0031] The wetting and dispersing agents have carboxyl- or hydroxyl-terminated functional groups.

[0032] The preparation method of above-mentioned water-based glue hardening agent, comprises the steps:

[0033] Step 1, the preparation of wetting and dispersing agent,

[0034] (1) Mix 600 grams of ricinoleic acid, 150 grams of triethylenetetramine and 20 grams of dibutyltin oxide to obtain pol...

Embodiment 2

[0043] A water-based glue hardener, including 10% sulfur, 13% accelerator, 5% wetting and dispersing agent, 4% thickener, 66% deionized water, 1.39% defoamer, 0.61% bactericide, The wetting and dispersing agent is sodium lauryl sulfate.

[0044] The thickener is methyl cellulose,

[0045] The defoamer is polydimethylsiloxane,

[0046] Described bactericide is the PreventolP91 of Germany Lanxess Company.

[0047] The preparation method of above-mentioned water-based glue hardening agent, comprises the steps:

[0048] (1) Add half of the deionized water, wetting and dispersing agent, sulfur and accelerator into the reaction kettle, stir at room temperature for 30 minutes,

[0049] (2) Start the circulating sander, and stir while circulating the grinding. After 3 hours, add the remaining deionized water, defoamer, and bactericide, and continue grinding and stirring for 1 hour.

[0050] (3) Add the thickener, continue to grind and stir for 2.5 hours, and obtain the water-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com