Electrostatic spinning film as well as preparation method thereof and application thereof in salinity gradient energy power generation

A technology of electrospinning and silk film, which is applied in the field of salt difference energy generation and electrospinning, to achieve the effects of improving performance, reducing impedance, and simplifying preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

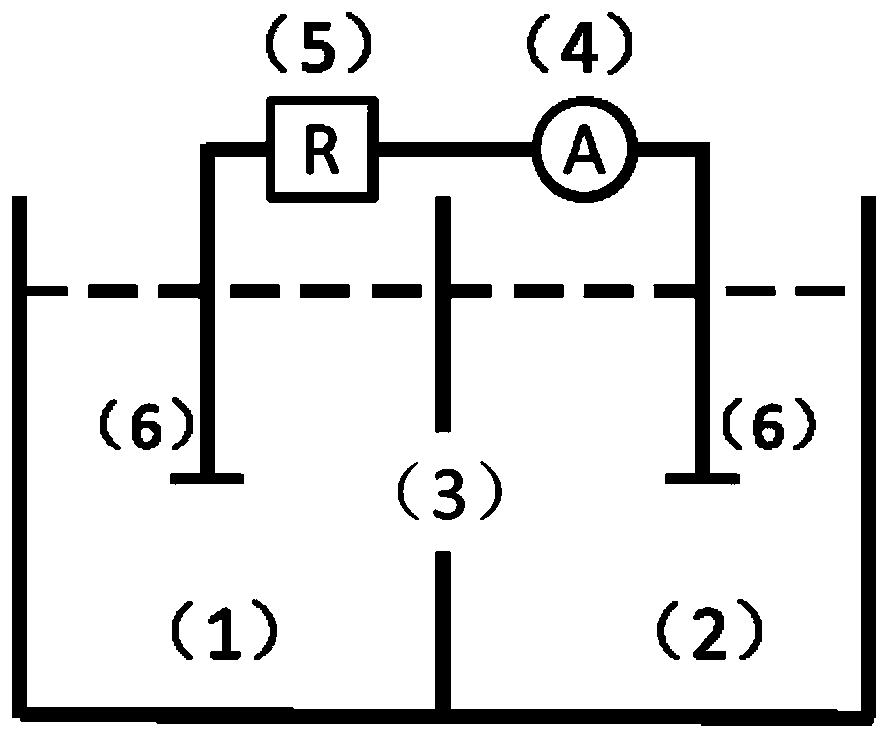

Method used

Image

Examples

Embodiment 1

[0071] (1) Preparation of double-layer electrospun film.

[0072] Dissolve polyvinyl alcohol in water to make 10% polyvinyl alcohol aqueous solution. Chitosan was dissolved in 50% acetic acid aqueous solution to prepare 5% chitosan solution. Get 10% polyvinyl alcohol solution and 5% chitosan solution to form a mixed solution, based on mass, polyvinyl alcohol in the mixed solution: chitosan=1:3, the mixed solution obtained is electrospun wire, aluminum foil was used to receive the electrospun membrane. With 2.5% by mass of glutaraldehyde, the obtained polyvinyl alcohol / chitosan electrospun film was cross-linked at 50° C. for 12 hours by steam method, and dried in an oven to obtain the polyvinyl alcohol / chitosan electrospun film . The sulfonated polyether sulfone is dissolved in DMF, a 15% solution is prepared, electrospinning is performed, and the cross-linked polyvinyl alcohol / chitosan electrospinning film is received to obtain a double-layer electrospinning film.

[0073]...

Embodiment 2

[0078] (1) Preparation of double-layer electrospun film.

[0079] Dissolve polyvinyl alcohol in water to make 10% polyvinyl alcohol aqueous solution. Chitosan was dissolved in 50% acetic acid aqueous solution to prepare 5% chitosan solution. Get 10% polyvinyl alcohol solution and 5% chitosan solution to form a mixed solution, based on mass, polyvinyl alcohol in the mixed solution: chitosan=1:4, the mixed solution obtained is electrospun wire, aluminum foil was used to receive the electrospun membrane. With 2.5% by mass of glutaraldehyde, the obtained polyvinyl alcohol / chitosan electrospun film was cross-linked at 50° C. for 12 hours by steam method, and dried in an oven to obtain the polyvinyl alcohol / chitosan electrospun film . The sulfonated polyether sulfone is dissolved in DMF, and a 15% solution is prepared for electrospinning, and received by a cross-linked polyvinyl alcohol / chitosan electrospinning film to obtain a double-layer electrospinning film.

[0080] (2) Sal...

Embodiment 3

[0084] Dissolve polyvinyl alcohol in water to make 10% polyvinyl alcohol aqueous solution. Chitosan was dissolved in 50% acetic acid aqueous solution to prepare 5% chitosan solution. Get 10% polyvinyl alcohol solution and 5% chitosan solution to form a mixed solution, based on mass, polyvinyl alcohol in the mixed solution: chitosan=1:6, the mixed solution obtained is electrospun wire, aluminum foil was used to receive the electrospun membrane. With 2.5% by mass of glutaraldehyde, the obtained polyvinyl alcohol / chitosan electrospun film was cross-linked at 50° C. for 12 hours by steam method, and dried in an oven to obtain the polyvinyl alcohol / chitosan electrospun film . The sulfonated polyether sulfone is dissolved in DMF, and a 15% solution is prepared for electrospinning, and received by a cross-linked polyvinyl alcohol / chitosan electrospinning film to obtain a double-layer electrospinning film.

[0085] For the test of the power generation performance of the salt differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com