Connection method of terminals and busbars of lithium ion single battery

A single battery and connection method technology, which is applied in the manufacture of battery pack components, battery boxes/jackets, electrolyte batteries, etc., can solve the problem that non-destructive testing of welding quality cannot be performed, rapid full inspection cannot be achieved, and welding quality is not controlled and other problems, to achieve the effect of low cost, good welding and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be noted that the embodiment is only an illustration of the gist of the present invention, rather than limiting the protection scope of the present invention.

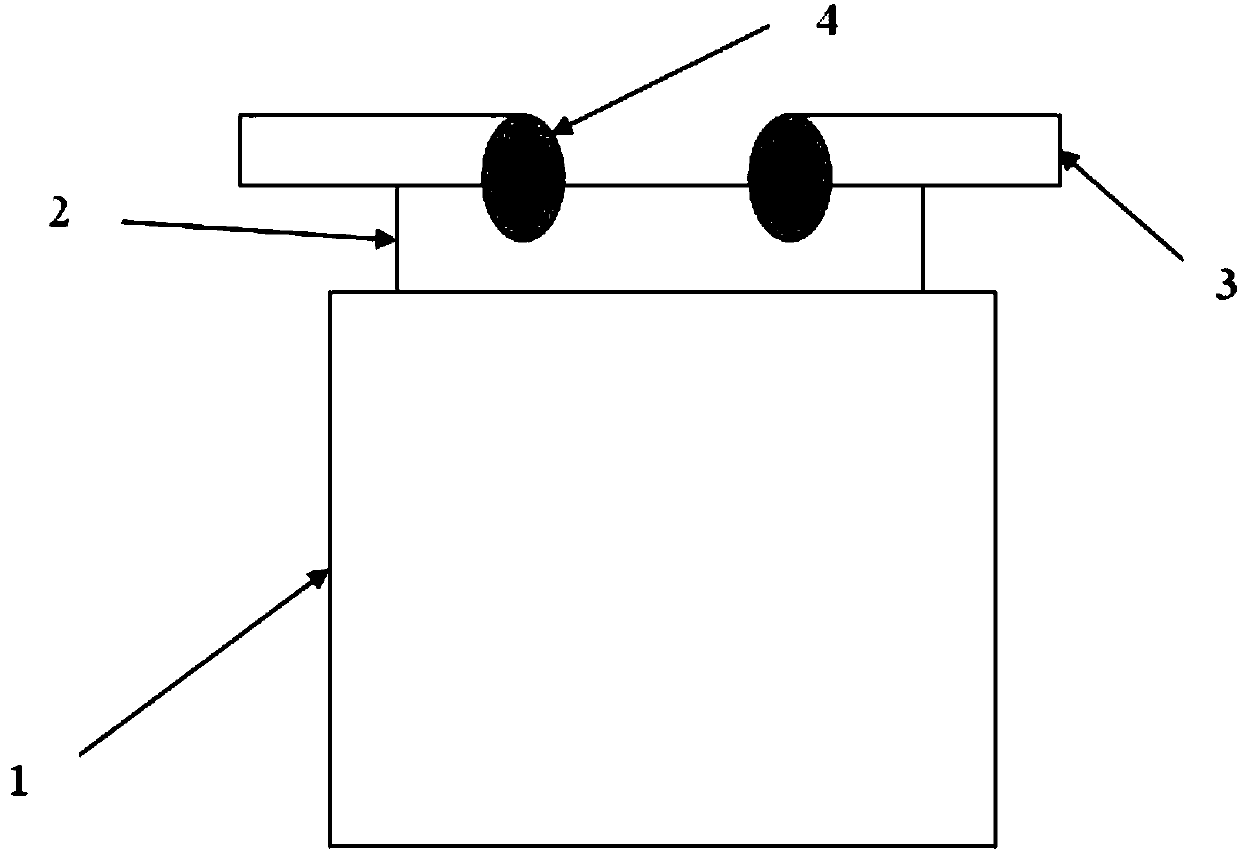

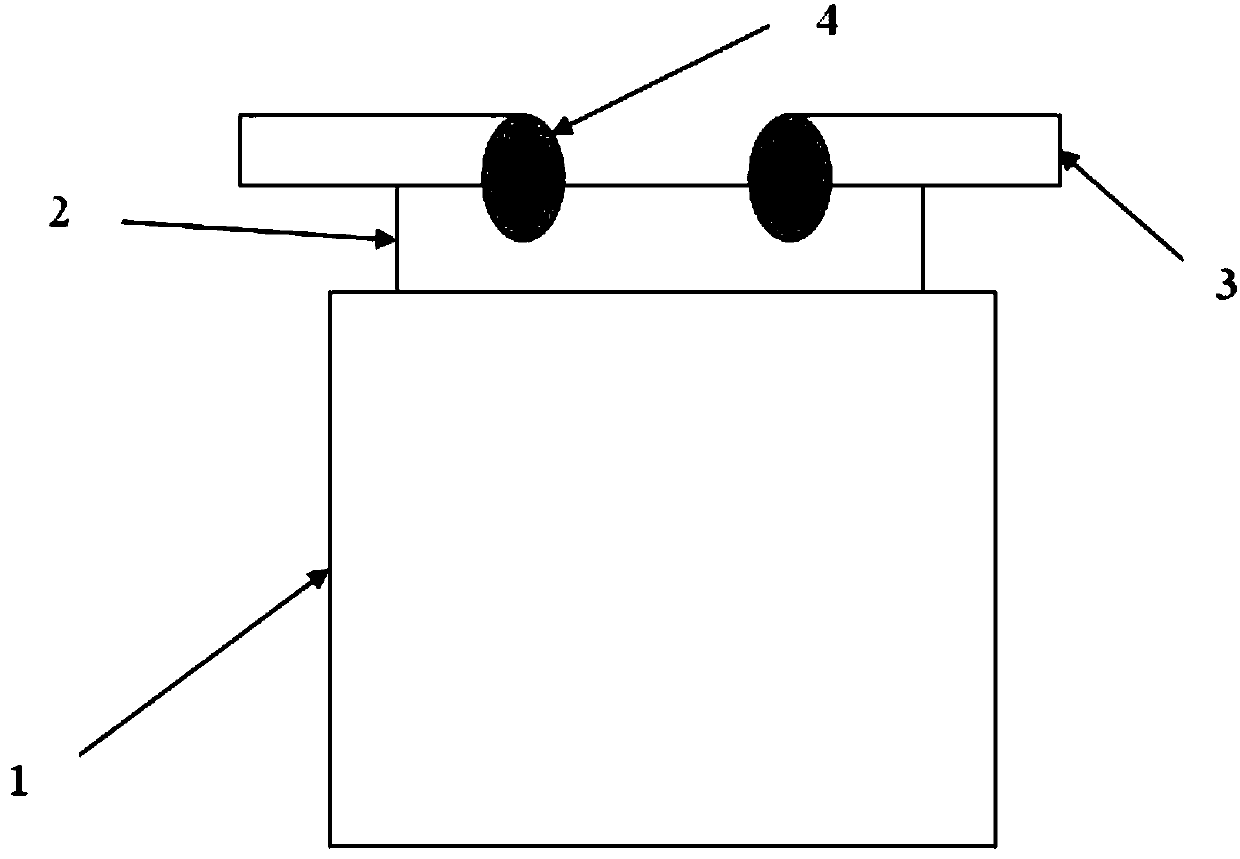

[0020] like figure 1 As shown, the present invention provides a method for connecting lithium-ion battery terminals and busbars, which includes the following steps:

[0021] 1) Position and press the output terminal 2 of the lithium-ion single battery 1 and the busbar 3 with tooling;

[0022] 2) Expose the output terminal 2 of the lithium-ion single battery and the welding connection surface 4 of the busbar;

[0023] 3) Connect the output terminal 2 of the lithium-ion single battery and the bus bar 3 by laser welding.

[0024] This implementation mode can be further realized through the following steps:

[0025] In the aforementioned method for connecting the terminals of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com