Odor pollutant control method for evaporation pond of in-situ leaching uranium mine

A control method and in-situ leaching uranium mining technology, which can be used in mining wastewater treatment, chemical instruments and methods, and neutralized water/sewage treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

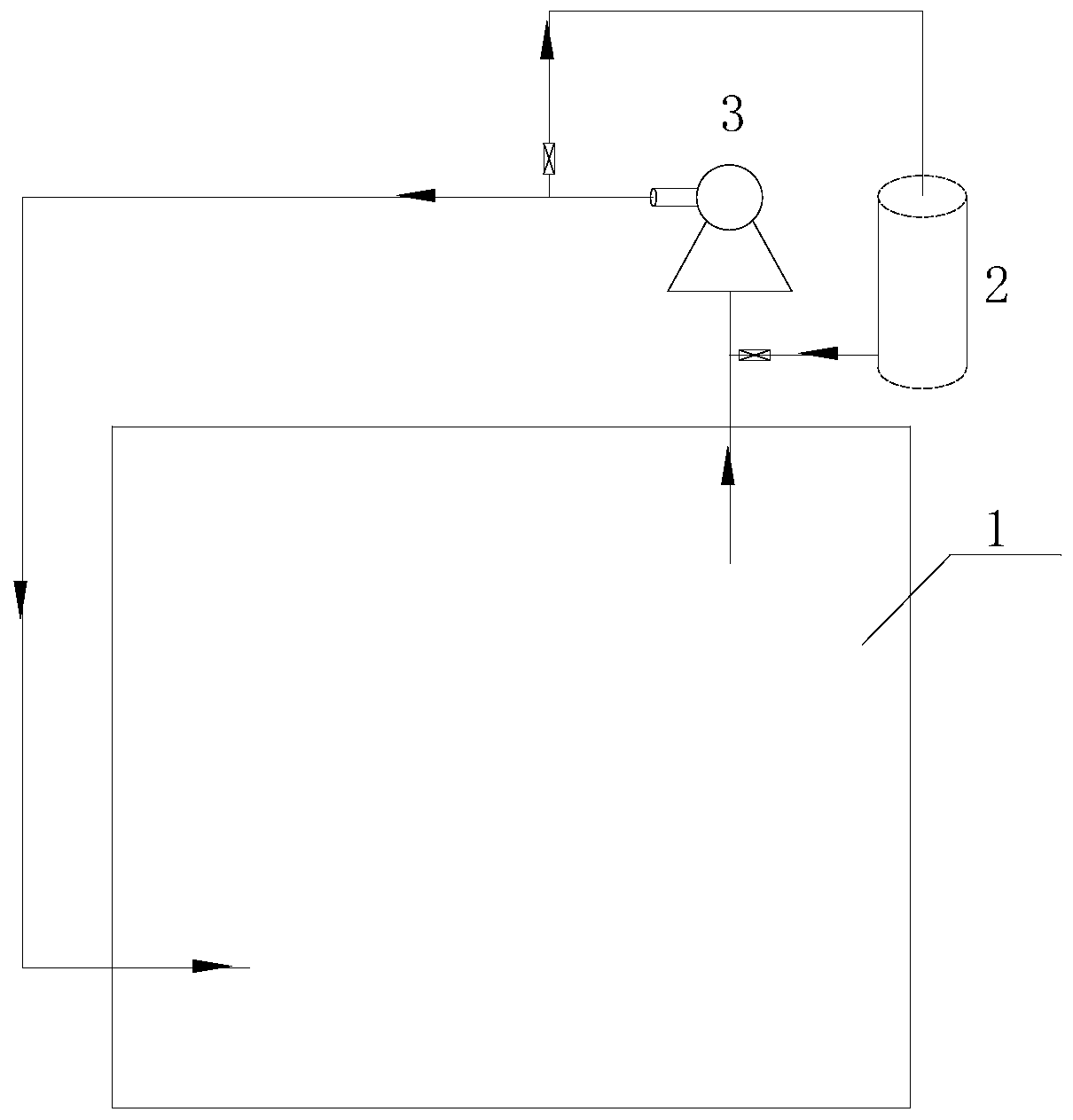

[0041] A method for controlling odorous pollutants in evaporation pond solution of in-situ leaching uranium mining mines, suitable for CO 2 +O 2 In-situ leaching of uranium mines, including the following steps:

[0042] Step 1: Install a circulation pump, reagent preparation tank and circulation pipeline on the edge of the evaporation pool;

[0043] Step 2: Add the mixed solution of dodecyl dimethyl benzyl ammonium chloride and sodium dichloroisocyanurate prepared in the preparation tank into the evaporation pool with a circulating pump;

[0044] The mass concentration of the mixed solution is 32 mg / L, and the mass ratio of dodecyldimethylbenzyl ammonium chloride to sodium dichloroisocyanurate is 3.5:1;

[0045] When the concentration of free chlorine in the evaporation pool reaches 6.5mg / L, stop adding the mixed solution, and the circulation pump continues to run for 24 hours to stir the wastewater in the evaporation pool evenly;

[0046] Step 3: Add the sodium hydroxide s...

Embodiment 2

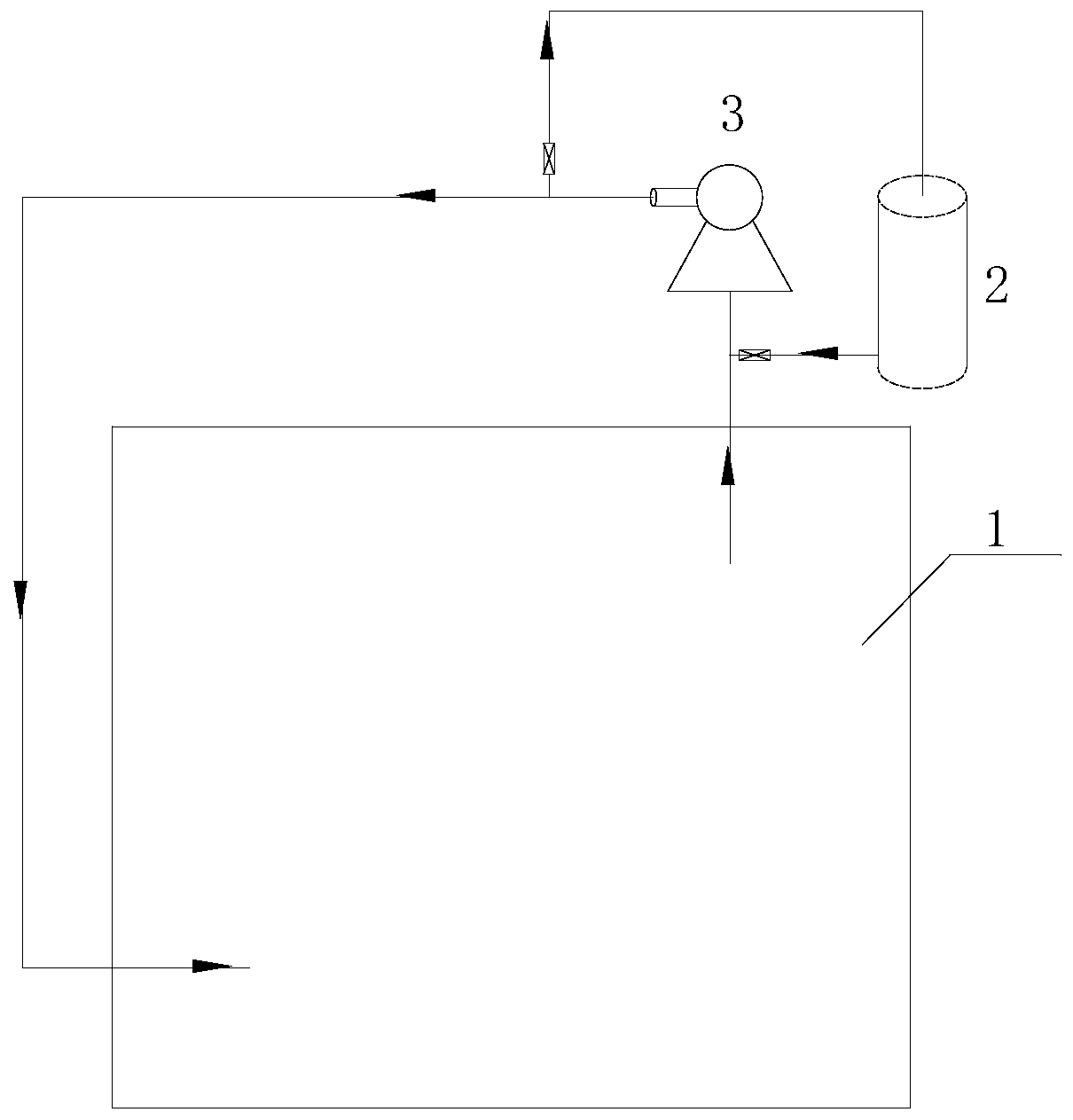

[0049] A method for controlling odorous pollutants in evaporation pond solution of in-situ leaching uranium mining mines, suitable for CO 2 +O 2 In-situ leaching of uranium mines, including the following steps:

[0050] Step 1: Install a circulation pump, reagent preparation tank and circulation pipeline on the edge of the evaporation pool;

[0051] Step 2: Add the mixed solution of dodecyl dimethyl benzyl ammonium chloride and sodium dichloroisocyanurate prepared in the preparation tank into the evaporation pool with a circulating pump;

[0052] The mass concentration of the mixed solution is 43mg / L, and the mass ratio of dodecyldimethylbenzyl ammonium chloride to sodium dichloroisocyanurate is 4.2:1;

[0053] When the concentration of free chlorine in the evaporation pool reaches 7.2mg / L, stop adding the mixed solution, and the circulation pump continues to run for 24 hours to stir the wastewater in the evaporation pool evenly;

[0054] Step 3: Add the sodium hydroxide so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com