Method for continuously preparing 2,5-furandiformic acid by using microchannel reaction device

A technology of channel reaction device and microchannel reaction, which is applied in the direction of organic chemistry, can solve the problems of high reactor design requirements, high energy consumption, poor selectivity, etc., and achieve good selectivity of target products, low reaction temperature and high reaction efficiency The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

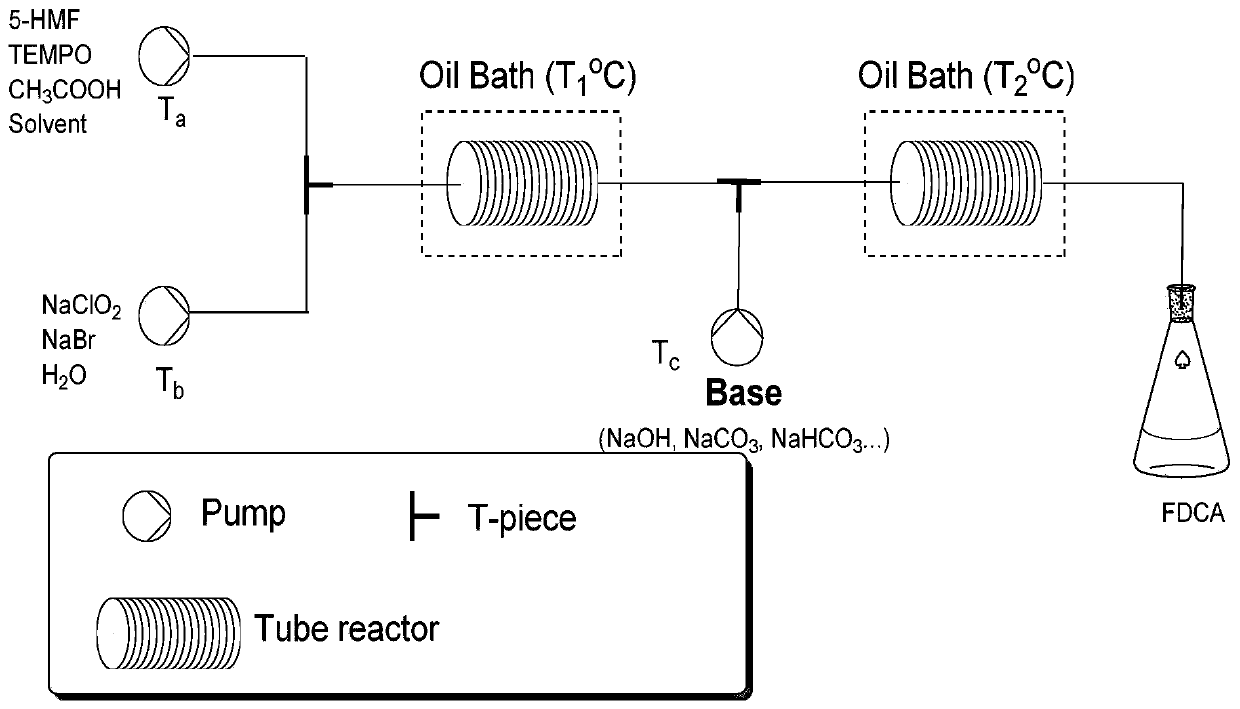

Method used

Image

Examples

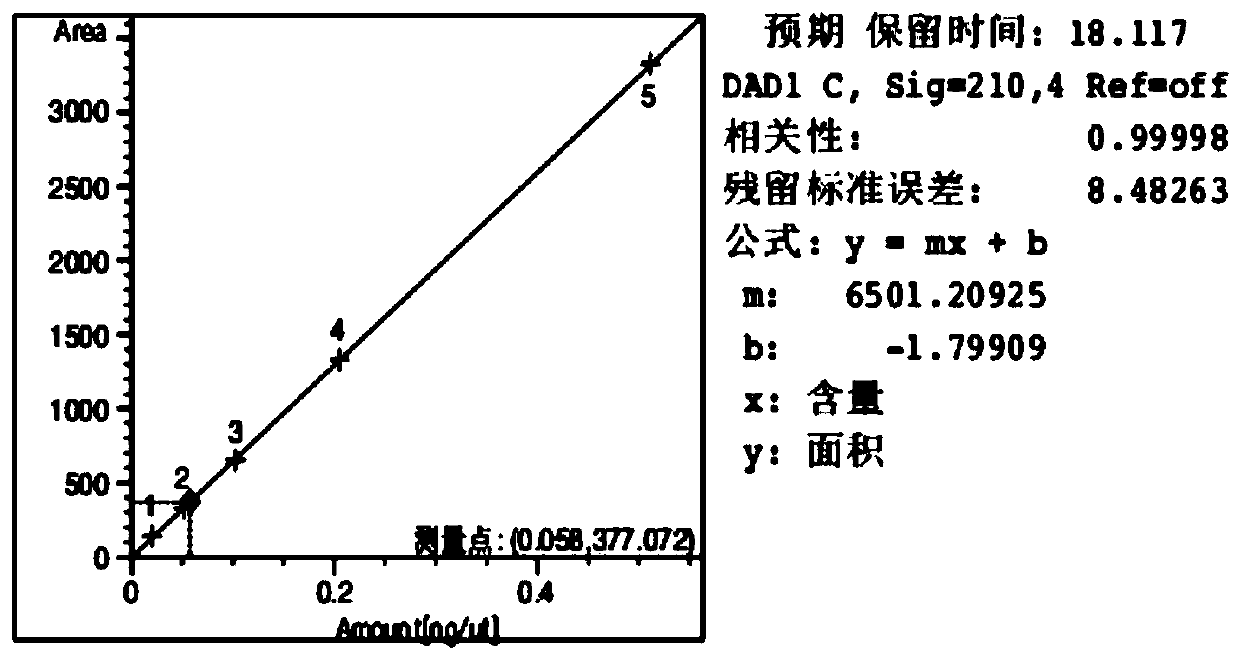

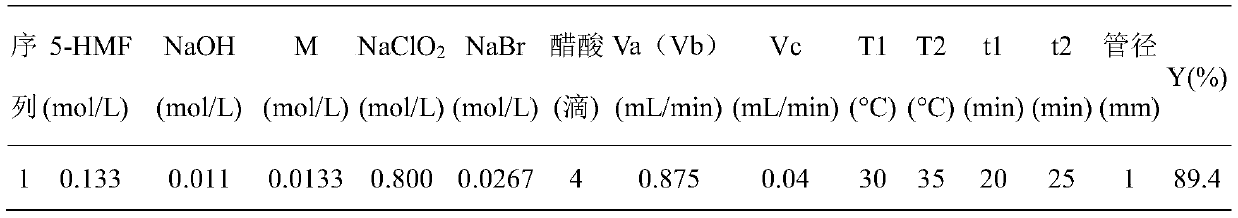

Embodiment 1

[0039]Weigh 0.504g of 5-hydroxymethylfurfural and 0.06g of 2,2,6,6-tetramethylpiperidine-N-oxide and dissolve them in 30mL of water, then add 4 drops of acetic acid dropwise within 1 minute, Stir at room temperature to mix evenly to make homogeneous solvent A and load it in a syringe. Weigh 0.08g of sodium bromide and 2.712g of sodium chlorite and dissolve them in 30mL of water, stir at room temperature to mix evenly to make a homogeneous solution B and load it into a syringe. Weigh 0.021g of sodium hydroxide and dissolve it in 10mL of water, stir at room temperature to make it evenly mixed to make a homogeneous solution C and load it into a syringe. The homogeneous solution A and the homogeneous solution B are pumped into the Y-type mixer at a flow rate of 0.875mL / min respectively, and after mixing, they are passed into the first microreactor with a coil inner diameter of 1mm. The volume of the reactor is 5mL. The temperature is controlled at 30°C, and the reaction residence...

Embodiment 2

[0041] Weigh 0.504g of 5-hydroxymethylfurfural and 0.06g of 2,2,6,6-tetramethylpiperidine-N-oxide and dissolve them in 30mL of water, then add 4 drops of acetic acid dropwise within 1 minute, Stir at room temperature to mix evenly to make a homogeneous solution A and load it in a syringe. Weigh 0.08g of sodium bromide and 2.712g of sodium chlorite and dissolve them in 30mL of water, stir at room temperature to mix evenly to make a homogeneous solution B and load it into a syringe. Weigh 0.021g of sodium hydroxide and dissolve it in 10mL of water, stir at room temperature to make it evenly mixed to make a homogeneous solution C and load it into a syringe. The homogeneous solution A and the homogeneous solution B are pumped into the Y-shaped mixer at a flow rate of 0.438mL / min respectively, and after mixing, they are passed into the first microreactor with a coil inner diameter of 1mm. The volume of the reactor is 10mL. The temperature is controlled at 40°C, and the reaction re...

Embodiment 3

[0043] Weigh 0.504g of 5-hydroxymethylfurfural and 0.06g of 2,2,6,6-tetramethylpiperidine-N-oxide and dissolve them in 30mL of water, then add 4 drops of acetic acid dropwise within 1 minute, Stir at room temperature to mix evenly to make a homogeneous solution A and load it in a syringe. Weigh 0.08g of sodium bromide and 2.712g of sodium chlorite and dissolve them in 30mL of water, stir at room temperature to mix evenly to make a homogeneous solution B and load it into a syringe. Weigh 0.021g of sodium hydroxide and dissolve it in 10mL of water, stir at room temperature to make it evenly mixed to make a homogeneous solution C and load it into a syringe. The homogeneous solution A and the homogeneous solution B are pumped into the Y-shaped mixer at a flow rate of 0.438mL / min respectively, and after mixing, they are passed into the first microreactor with a coil inner diameter of 1mm. The volume of the reactor is 15mL. The temperature is controlled at 50°C, and the reaction re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com