Modified cationic waterborne polyurethane color fixing agent and preparation method thereof

A water-based polyurethane and cationic technology, which can be used in dyeing, textiles and papermaking, etc., can solve the problems of poor hand feeling, achieve improved wear resistance and washability, simple preparation process, and excellent color fixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

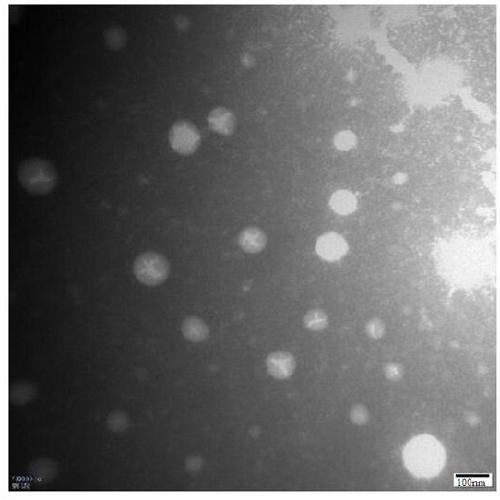

Image

Examples

Embodiment 1

[0024] (1) Quaternization reaction: Add 12.0 g of nitrogen methyldiethanolamine (diluted with isopropanol to a mass fraction of 30%) into a three-necked flask, mix and stir, and slowly add 11.2 g of Oxychloropropane. Then the temperature was raised to 60°C, and the reaction was stirred for 6 h to obtain a hydroxyl-terminated quaternary ammonium salt chain extender. The obtained product was washed three times with acetone, the residual solvent was distilled off under reduced pressure, and dried at 45°C and 0.09 Mpa vacuum for 24 h.

[0025] (2) Prepolymerization reaction: Add 10.5 g polyethylene glycol (Mn=1000), 4.5 g polyether glycol N210 and 0.45 g castor oil into the reactor, and heat at a constant temperature in a water bath at 90°C and a vacuum of 0.095Mpa After dehydration for 1.5 h, the moisture content was measured to be <0.1%, and 6.67 g of IPDI was added after cooling down, and reacted at 75°C for 2.5 h. Then, the temperature was lowered to 45°C and 1.08 g of hydro...

Embodiment 2

[0028] (1) Quaternization reaction: Add 12.0 g of nitrogen methyldiethanolamine (diluted with isopropanol to a mass fraction of 30%) into a three-necked flask, mix and stir, and slowly add 11.2 g of Oxychloropropane. Then the temperature was raised to 60°C, and the reaction was stirred for 6 h to obtain a hydroxyl-terminated quaternary ammonium salt chain extender. The obtained product was washed three times with acetone, the residual solvent was distilled off under reduced pressure, and dried at 45°C and 0.09 Mpa vacuum for 24 h.

[0029] (2) Prepolymerization reaction: Add 10.5 g of polyethylene glycol (Mn=1000), 7 g of polyether glycol N210 and 0.53 g of castor oil into the reactor, and heat at a constant temperature in a 90°C water bath and a vacuum of 0.095Mpa After dehydration for 1.5 h, the moisture content was measured to be <0.1%, and 6.67 g of IPDI was added after cooling down, and reacted at 75°C for 2.5 h. Then, the temperature was lowered to 45°C and 1.32 g of h...

Embodiment 3

[0032] (1) Quaternization reaction: Add 12.0 g of nitrogen methyldiethanolamine (diluted with isopropanol to a mass fraction of 30%) into a three-necked flask, mix and stir, and slowly add 13.1 g of ring Oxychloropropane. Then the temperature was raised to 60°C, and the reaction was stirred for 6 h to obtain a hydroxyl-terminated quaternary ammonium salt chain extender. The obtained product was washed three times with acetone, the residual solvent was distilled off under reduced pressure, and dried at 45°C and 0.09 Mpa vacuum for 24 h.

[0033] (2) Prepolymerization reaction: Add 10.5 g polyethylene glycol (Mn=1000), 10.5 g polyether glycol N210 and 0.84 g castor oil into the reactor, and heat at a constant temperature in a water bath at 90°C and a vacuum of 0.095Mpa After dehydration for 1.5 h, the moisture content was measured to be <0.1%, and 6.67 g of IPDI was added after cooling down, and reacted at 75°C for 2.5 h. Then, the temperature was lowered to 45°C and 1.46 g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com