Macroporous temperature sensitive amphiphilic hydrogel material and preparation method thereof

A technology of amphiphilic and temperature-sensitive monomers, applied in the field of functional polymer materials, can solve problems such as reducing material transfer efficiency, achieve amphiphilicity and low internal transfer resistance, improve gel surface pore structure, increase The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 prepares hydrogel material PNIPAM

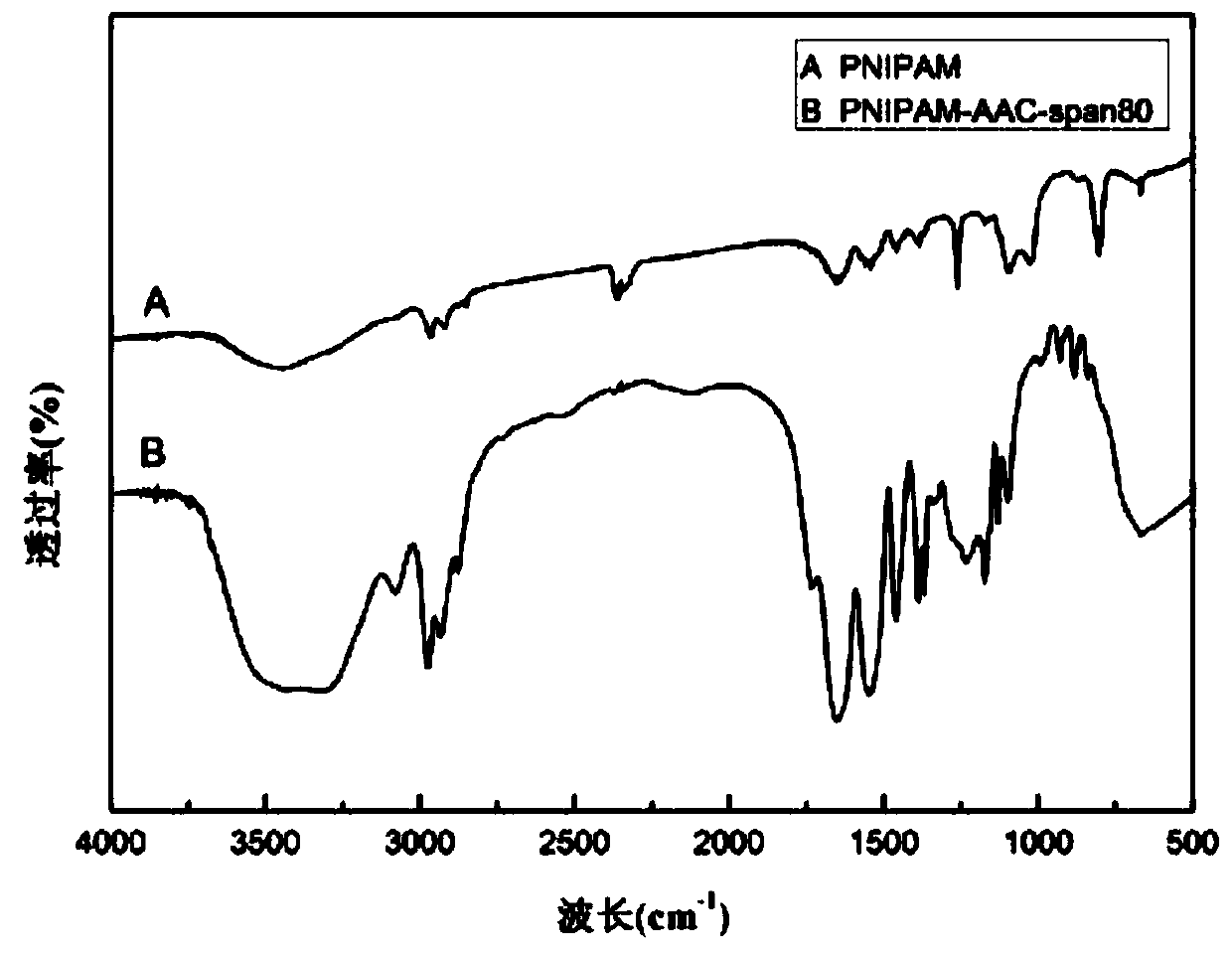

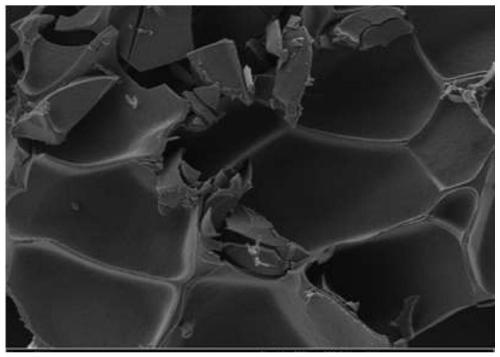

[0038] Weigh 1g monomer N-isopropylacrylamide (NIPAM), 0.02g initiator azobisisobutyronitrile (AIBN), 0.1g coupling agent N,N'-methylenebisacrylamide (MBAA), Then add an ethanol solution with a mass percentage content of 50%, place the added flask in a water bath at 75° C. for reaction, and take out the flask after the reaction to obtain the gel material PNIPAM. The infrared spectrum of the prepared gel material PNIPAM is as follows figure 2 , SEM such as image 3 .

Embodiment 2

[0039] Example 2 Preparation of the esterification product of acrylic acid and span80, i.e. the hydrophobic monomer AAc-span80

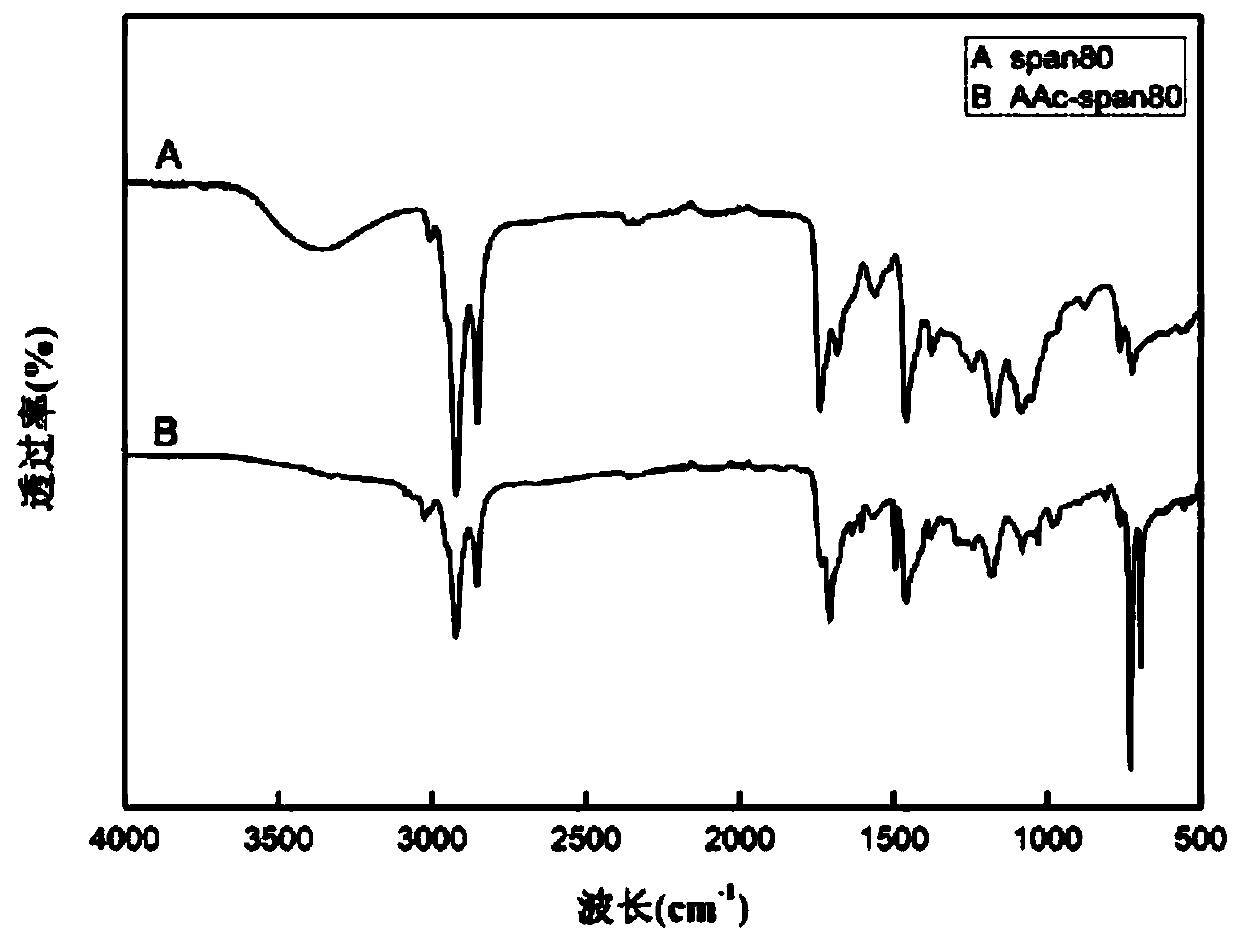

[0040] Weigh 4.826g span80 and 20mL toluene into the flask, stir and heat to 80℃~150℃, then add 0.72g acrylic acid, 0.044g hydroquinone, 0.388g p-toluenesulfonic acid, and react until no water is discharged from the water separator; Add the reaction product to the separatory funnel, first with Na 2 CO 3 Solution washing to remove excess acrylic acid and p-toluenesulfonic acid, after washing, let stand for stratification, then wash with NaCl solution, remove the water phase after standing for stratification, and obtain the supernatant brown oil, which is the esterification product AAc- The mixture of span80 and toluene; the mixture of AAc-span80 and toluene was rotary distilled until the quality of the product no longer changed, and the purified esterification product AAc-span80 was obtained. The infrared spectrum of the prepared esterification prod...

Embodiment 3

[0041] Example 3 Preparation of macroporous thermosensitive amphiphilic hydrogel material PNIPAM-AAc-span80

[0042] Weigh 1g monomer N-isopropylacrylamide (NIPAM), 0.03g monomer acrylic acid (AAc) and span80 esterification product AAc-span80, 0.02g initiator azobisisobutyronitrile (AIBN), 0.2g Coupling agent N,N'-methylenebisacrylamide (MBAA), and then add 50% ethanol solution by mass percentage, place the added flask in a water bath at 75°C for reaction, and put The flask was taken out to obtain the macroporous thermosensitive amphiphilic gel material PNIPAM-AAc-span80.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap