Pigment derivative, pigment for polyurethane ink, and preparation method for both

A technology of pigment derivatives and compounds, applied in the field of organic pigment yellow 13 and its preparation, can solve problems such as high viscosity, and achieve the effects of reducing ink cost, high tinting strength and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0081] [Example 1] Synthesis of Hue Adjuster

[0082] Add 150ml of water and 20g of hydrochloric acid in the reaction tank, add 5g of dianisidine under stirring, and disperse for 30 minutes. Add ice to the reaction tank to lower the temperature, the temperature is -5-0°C, add 15g of sodium nitrite for diazotization reaction, starch potassium iodide test paper detects slightly blue, and stir for 30 minutes. Excessive sodium nitrite was destroyed with sulfamic acid, tested by starch potassium iodide test paper, showing colorless, and a hue adjusting agent solution was obtained.

[0083]

[0084] Anisidine

[0085] Reaction equation NaNO 2 +HCl→HNO 2 +NaCl

[0086] QUR 2 +2HCl+NaNO 2 →ArN 2 + Cl - +NaCl+2H 2 o

[0087] Wherein Ar represents dianisidine.

example 2

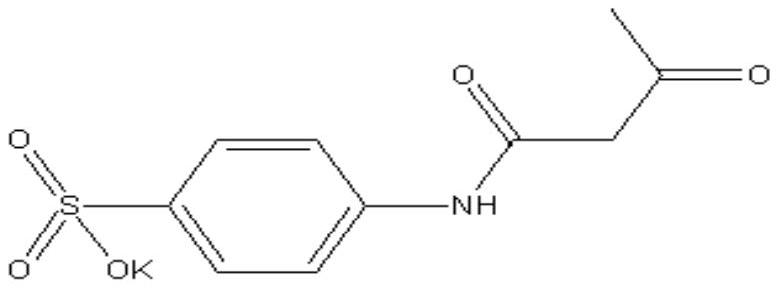

[0088] 【Example 2】Pigment Derivatives I

[0089] Pigment derivative I was synthesized by the following method:

[0090] 1. Diazotized components

[0091] Add 500ml of water and 30g of hydrochloric acid into a small diazotization reaction tank, add 35g of 3,3-dichlorobenzidine under stirring, and disperse and stir for 60 minutes. Add ice to the small diazotization reaction tank, the temperature is -5-0°C, add 20g of sodium nitrite for diazotization reaction until the starch potassium iodide test paper is slightly blue, stir for 60 minutes, and obtain the diazonium salt solution of the pigment derivative .

[0092] 2. Coupling components

[0093] Add 2000ml of water to the small coupling reaction tank, add 50g of sodium carbonate, add 55g of acetic acid under stirring, adjust the pH=6.5-7, add 20g of acetoacetanilide and 37g of p-sulfonic acid acetoacetanilide, and stir for 60 minutes to obtain the pigment Coupling components for derivatives.

[0094] Reaction equation Ar'-...

example 3

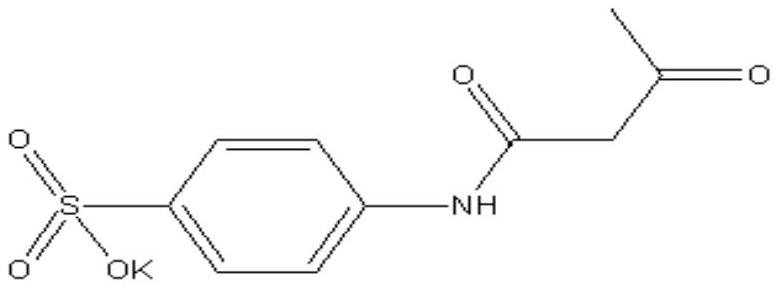

[0102] 【Example 3】Pigment derivative II

[0103] Pigment Derivative II was synthesized by the following method:

[0104] 1. Diazotized components

[0105] Add 500ml of water and 30g of hydrochloric acid into a small diazotization reaction tank, add 35g of 3,3-dichlorobenzidine under stirring, and disperse and stir for 60 minutes. Add ice to the small diazotization reaction tank to cool down, the temperature is -5-0°C, add 20g of sodium nitrite to carry out diazotization reaction until the starch potassium iodide test paper is slightly blue, and stir for 60 minutes to obtain a pigment derivative diazonium salt solution.

[0106] 2. Coupling components

[0107] Add 2000ml of water to the small coupling reaction tank, add 20g of sodium hydroxide solution, add 19g of o-methyl acetoacetanilide, then add 40g of p-sulfonic acid acetoacetanilide, dissolve until the solution is transparent, add 50g of acetic acid under stirring , adjust the pH=6-7, and stir for 60 minutes to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luster | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com