High strength anticorrosive emulsion paint

A high-strength, latex paint technology, applied in latex paint, anti-corrosion coatings, coatings, etc., can solve the problems of low strength and easy to be corroded, and achieve the effect of strong covering ability, strong adhesion, elegant and warm flat decoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

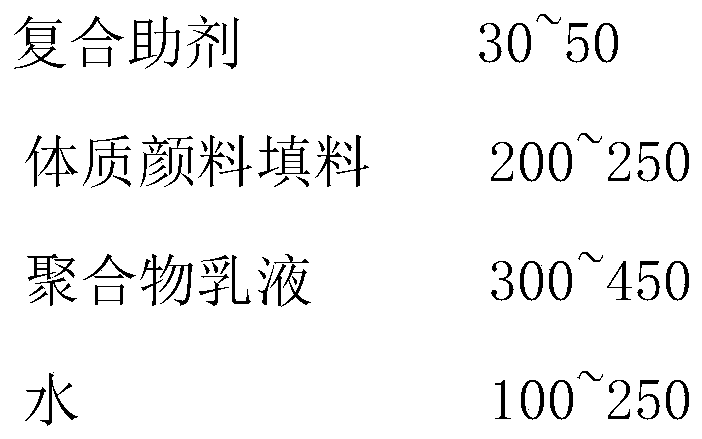

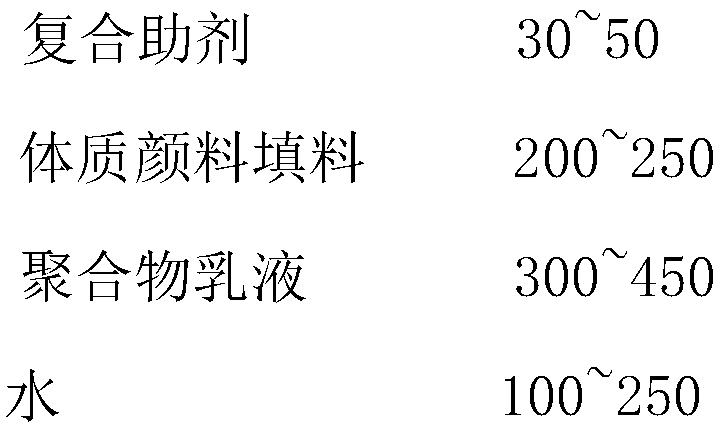

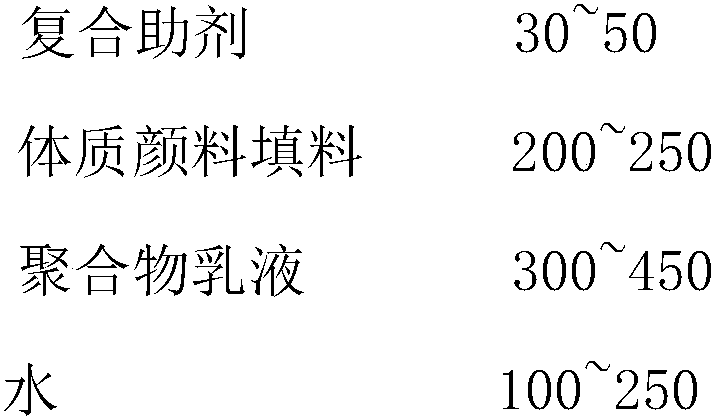

Method used

Image

Examples

Embodiment 1

[0025] Prepare this high-strength anticorrosion latex paint by the following steps:

[0026] Step 1: 0.3 parts by weight of defoamer, 0.2 parts by weight of antifungal agent, 0.3 parts by weight of preservative, 0.3 parts by weight of whitening agent, 0.4 parts by weight of dispersant, 0.2 parts by weight of thickener, 0.2 parts by weight of initiator, Add 0.4 parts by weight of wetting agent, 2 parts by weight of hydrophobic additives and 0.2 parts by weight of hydroxycellulose into 100 parts by weight of water and mix and stir evenly to obtain composite additives;

[0027] Step 2: Mix and stir 4 parts by weight of porous powder quartz, 2 parts by weight of anatase nano-TiO2 and 14 parts by weight of rutile-type nano-TiO2 to obtain an extender pigment filler;

[0028] Step 3: Mix and stir the composite additive in step 1 and the extender pigment filler in step 2 to obtain mixture 1;

[0029] Step 4: Mix and stir 15 parts by weight of silicone-modified acrylic emulsion, 2 par...

Embodiment 2

[0032] Step 1: 0.4 parts by weight of defoaming agent, 0.3 parts by weight of antifungal agent, 0.4 parts by weight of preservative, 0.4 parts by weight of whitening agent, 0.6 parts by weight of dispersant, 0.3 parts by weight of thickener, 0.4 parts by weight of initiator, 0.6 parts by weight of wetting agent, 3 parts by weight of hydrophobic auxiliary agent and 0.3 part by weight of hydroxycellulose are added to 150 parts by weight of water and mixed and stirred evenly to obtain a composite auxiliary agent;

[0033] Step 2: 6 parts by weight of porous powder quartz, 2 parts by weight of anatase nano-TiO2 and 15 parts by weight of rutile-type nano-TiO2 are mixed and stirred evenly to obtain an extender pigment filler;

[0034] Step 3: Mix and stir the composite additive in step 1 and the extender pigment filler in step 2 to obtain mixture 1;

[0035] Step 4: Mix and stir 17 parts by weight of silicone-modified acrylic emulsion, 3 parts by weight of perfluorosiloxane resin an...

Embodiment 3

[0038] Step 1: 0.5 parts by weight of defoamer, 0.4 parts by weight of antifungal agent, 0.5 parts by weight of preservative, 0.5 parts by weight of whitening agent, 0.7 parts by weight of dispersant, 0.3 parts by weight of thickener, 0.6 parts by weight of initiator, 0.7 parts by weight of wetting agent, 4 parts by weight of hydrophobic auxiliary agent and 0.3 part by weight of hydroxycellulose are added to 200 parts by weight of water and mixed and stirred evenly to obtain a composite auxiliary agent;

[0039] Step 2: 7 parts by weight of porous powder quartz, 3 parts by weight of anatase nano-TiO2 and 16 parts by weight of rutile-type nano-TiO2 are mixed and stirred evenly to obtain an extender pigment filler;

[0040] Step 3: Mix and stir the composite additive in step 1 and the extender pigment filler in step 2 to obtain mixture 1;

[0041] Step 4: Mix and stir 18 parts by weight of silicone-modified acrylic emulsion, 4 parts by weight of perfluorosiloxane resin and 11 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com