High-performance supercapacitor electrode materials and preparation method thereof

A technology of supercapacitors and electrode materials, applied in the field of chemistry, can solve the problems of poor conductivity and inevitable reduction, and achieve the effects of low cost, low price and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

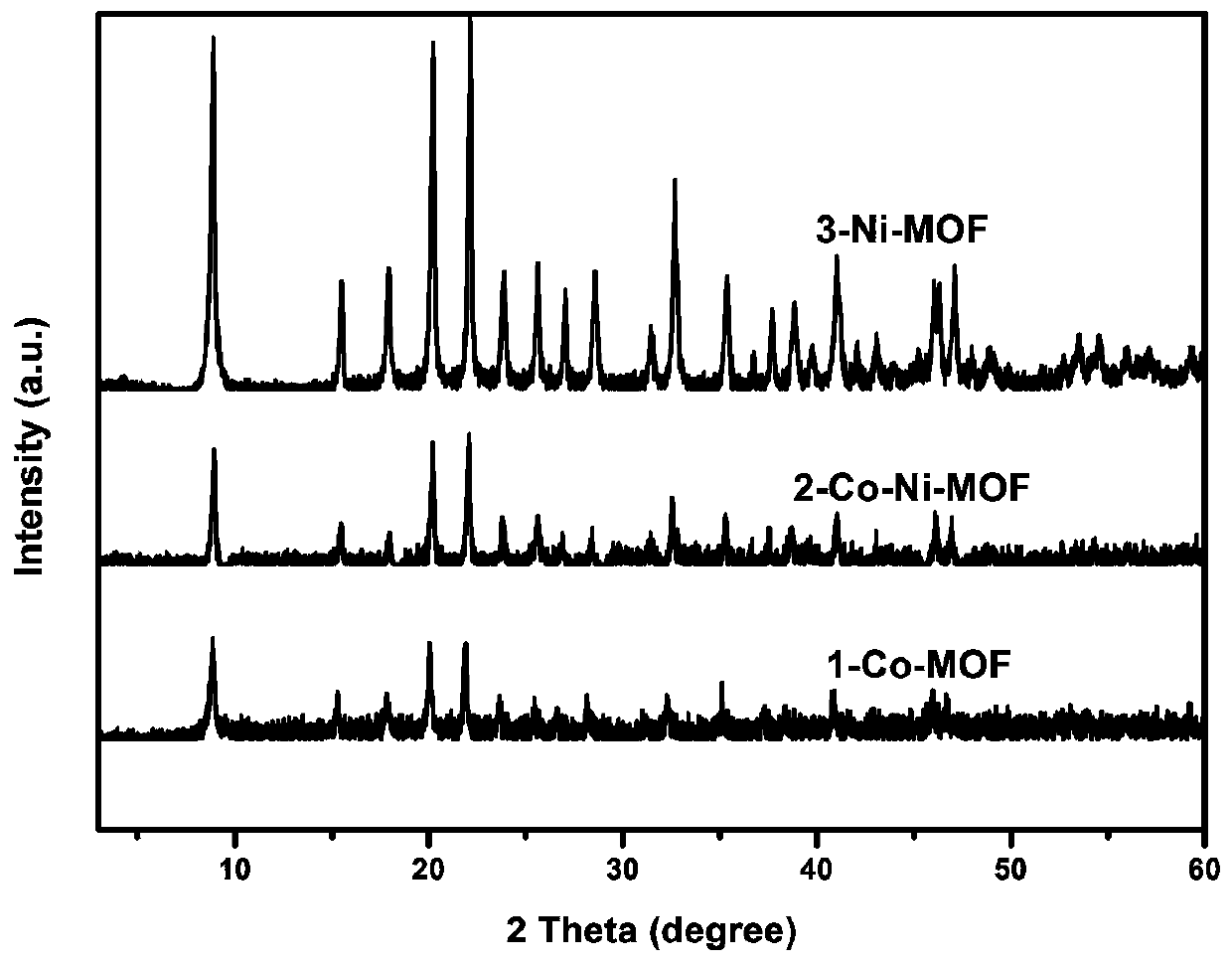

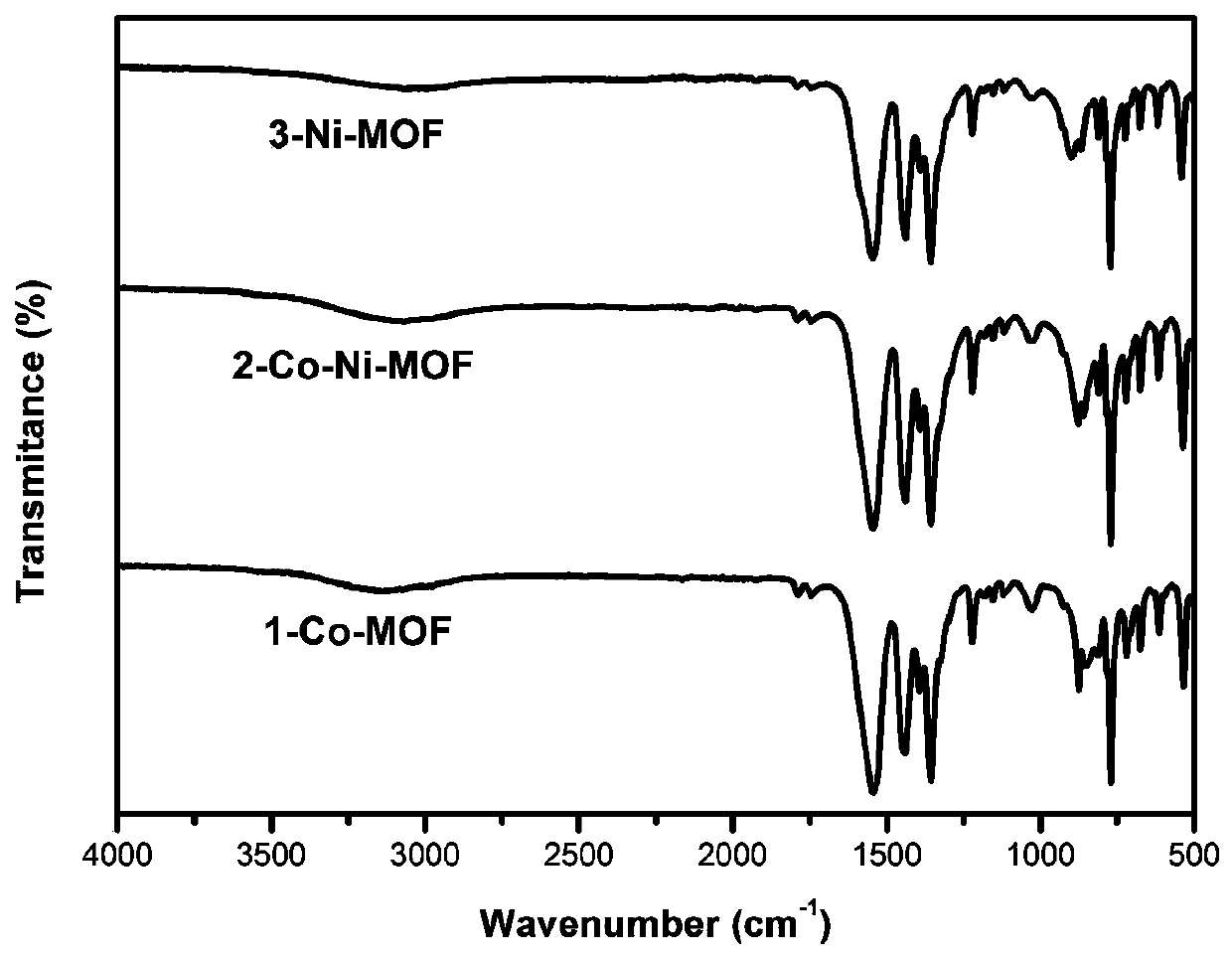

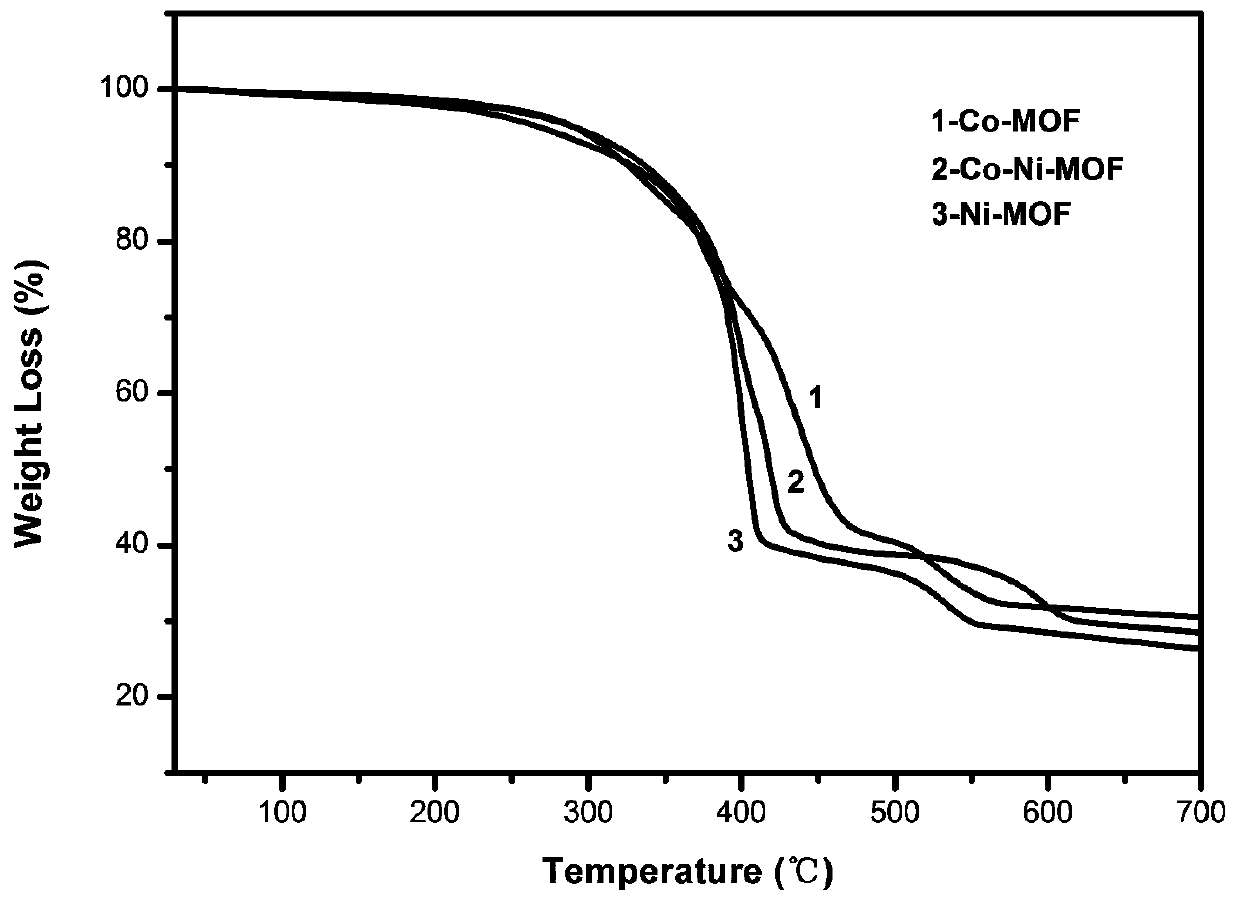

[0036] Embodiment 1: Ni-based two-dimensional MOF supercapacitor electrode material

[0037] Step1: At room temperature, weigh 200mg Ni(NO 3 ) 2 ·6H 2 O and 100 mg of 1,4,5,8-naphthalene tetracarboxylic dianhydride were mixed to obtain a mixture.

[0038] Step2: Add the above mixture into a 20ml autoclave equipped with a mixed solvent consisting of 5ml N,N'-dimethylformamide, 5ml ethanol and 5ml water, and stir for 0.5h to obtain a uniformly mixed solution.

[0039] Step3: Heat the homogeneously mixed solution above at 120°C for 24h.

[0040] Step4: Heat the above heat-treated solution at 15°C·h -1 Cool down at the cooling rate until it cools down to room temperature.

[0041] Step5: Filter the mother liquor, wash the obtained solid with ethanol several times, and finally heat and dry to obtain a powder. This powder is the Ni-based two-dimensional MOF supercapacitor electrode material, which is recorded as Ni-MOF.

Embodiment 2

[0042] Embodiment 2: Co-based two-dimensional MOF supercapacitor electrode material

[0043] Step1: At room temperature, weigh 200mg Co(NO 3 ) 2 ·6H 2 O and 100 mg of 1,4,5,8-naphthalene tetracarboxylic dianhydride were mixed to obtain a mixture.

[0044] Step2: Add the above mixture into a 20ml autoclave equipped with a mixed solvent consisting of 5ml N,N'-dimethylformamide, 5ml ethanol and 5ml water, and stir for 0.5h to obtain a uniformly mixed solution.

[0045] Step3: Heat the homogeneously mixed solution above at 120°C for 24h.

[0046] Step4: Heat the above heat-treated solution at 15°C·h -1 Cool down at the cooling rate until it cools down to room temperature.

[0047] Step5: Filter the mother liquor, wash the obtained solid with ethanol several times, and finally heat and dry to obtain a powder. This powder is the Co-based two-dimensional MOF supercapacitor electrode material, which is denoted as Co-MOF.

Embodiment 3

[0048] Embodiment 3: Ni-Co doped two-dimensional MOF supercapacitor electrode material

[0049] Step1: At room temperature, weigh 100mg Co(NO 3 ) 2 ·6H 2 O, 100mgNi(NO 3 ) 2 ·6H 2 O and 100 mg of 1,4,5,8-naphthalene tetracarboxylic dianhydride were mixed to obtain a mixture.

[0050] Step2: Add the above mixture into a 20ml autoclave equipped with a mixed solvent consisting of 5ml N,N'-dimethylformamide, 5ml ethanol and 5ml water, and stir for 0.5h to obtain a uniformly mixed solution.

[0051] Step3: Heat the homogeneously mixed solution above at 120°C for 24h.

[0052] Step4: Heat the above heat-treated solution at 15°C·h -1 Cool down at the cooling rate until it cools down to room temperature.

[0053] Step5: Filter the mother liquor, wash the obtained solid with ethanol several times, and finally heat and dry to obtain a powder. The powder is Ni-Co doped two-dimensional MOF supercapacitor electrode material, which is recorded as Ni-Co-MOF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com