A method, device and application of thinning silicon carbide sheet

A technology of silicon carbide wafers and silicon carbide, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problem of unsuitable silicon carbide wafers, unsatisfactory thinning effects, silicon carbide wafers or silicon carbide wafers No problems such as thinning scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] The method for thinning silicon carbide wafers in this example includes pretreatment, deposition step, protective film removal step, thermal reaction step, film protection step, acid corrosion step, water washing step, mechanical grinding step and protective film removal step; Processing can be selected according to requirements. Each step is detailed as follows:

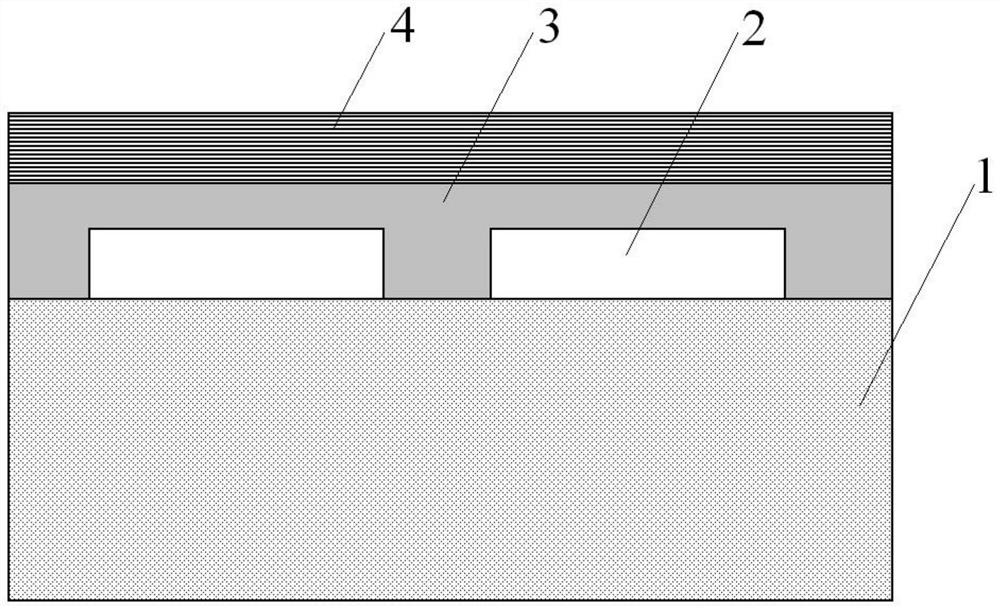

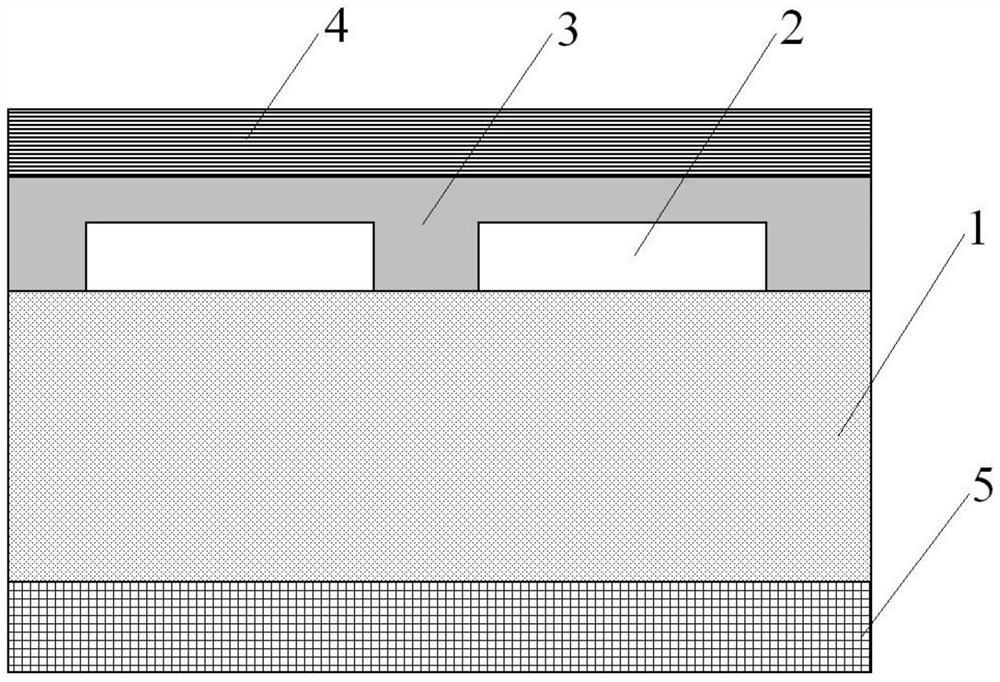

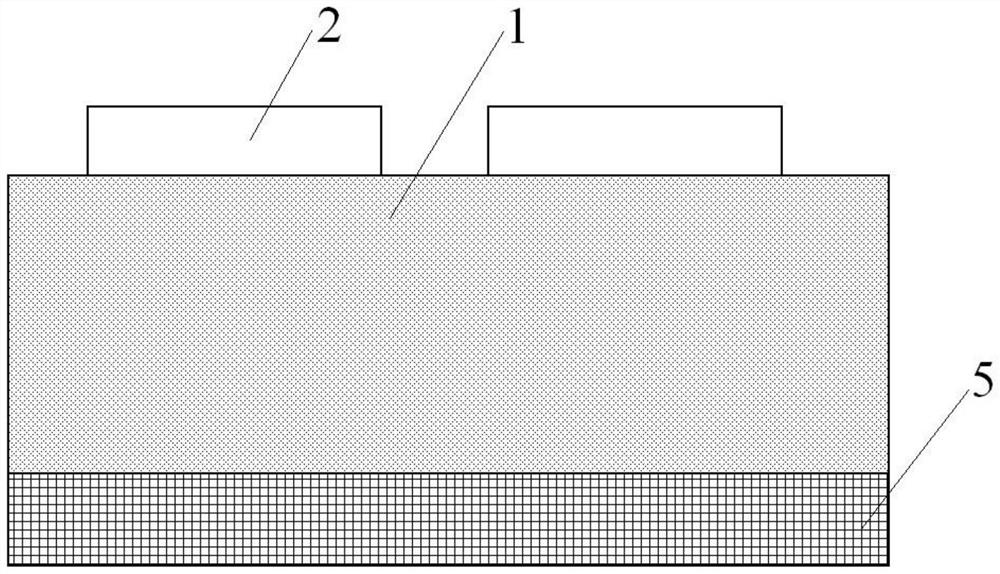

[0060] Pretreatment: After the normal silicon carbide wafer front-side device production process is completed, the front side of the silicon carbide wafer is coated with photoresist. Generally, the coating thickness of photoresist is 0.5-5μm, and then the front side is pasted with blue membrane protection, such as figure 1 as shown, figure 1 Among them, 1 is the silicon carbide wafer, 2 is the front device of the silicon carbide wafer, 3 is the photoresist, and 4 is the blue film; after pasting the blue film for protection, the silicon carbide wafer is soaked with 1% hydrofluoric acid After 0.5 to 10 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com