Preparation method of BiVO4/2D g-C3N4Z type heterojunction photocatalyst

A 2dg-c3n4, 2dg-c3n4z technology, which is applied in the field of preparation of BiVO4/2Dg-C3N4Z heterojunction photocatalysts, can solve the problem that the synergy is difficult to exert effectively, the photogenerated electron-hole pair recombination rate is high, and the photogenerated current carrying The problem of large electron transport distance, etc., to achieve the effect of rapid separation and electron migration ability, promote efficient charge separation, and promote efficient separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

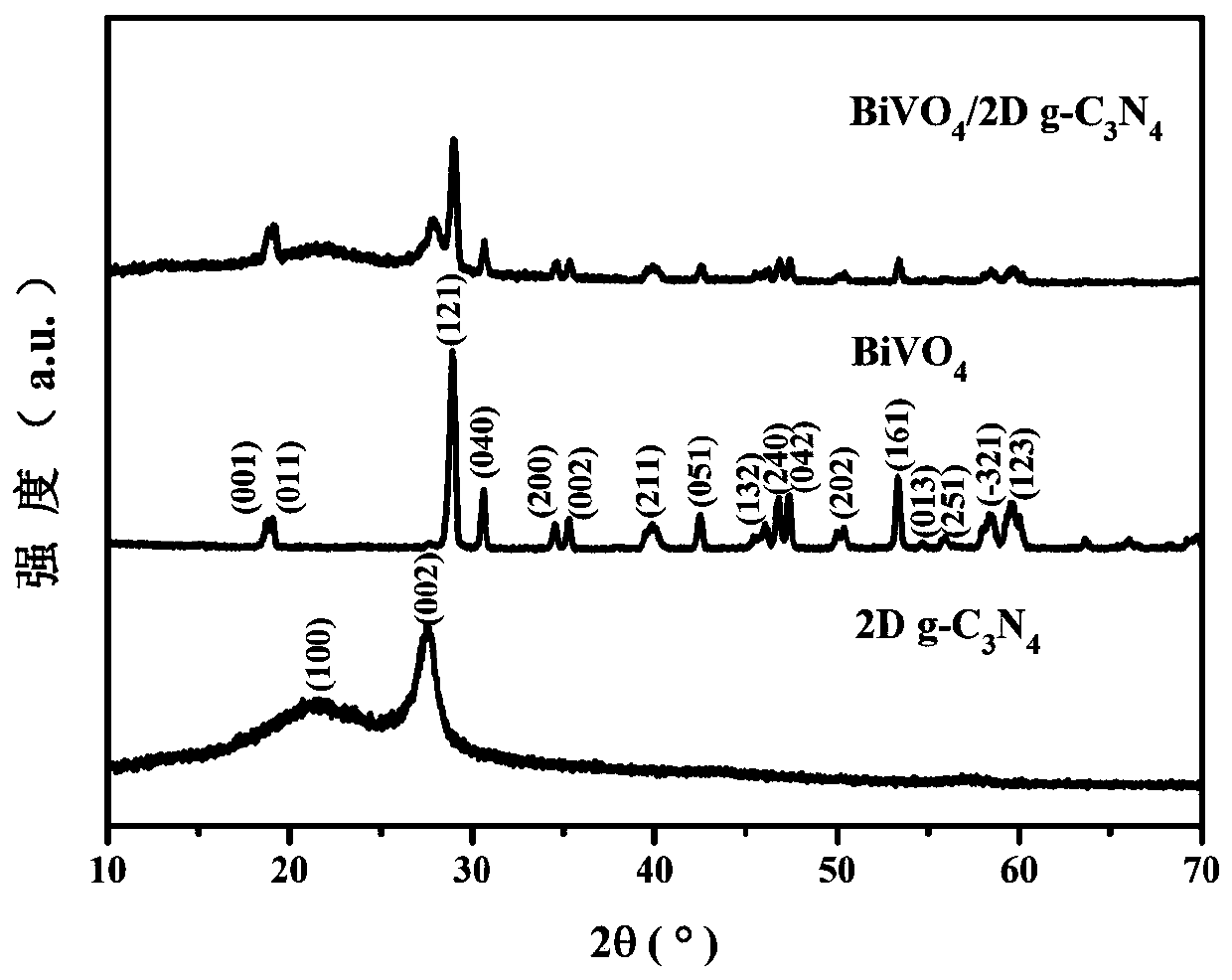

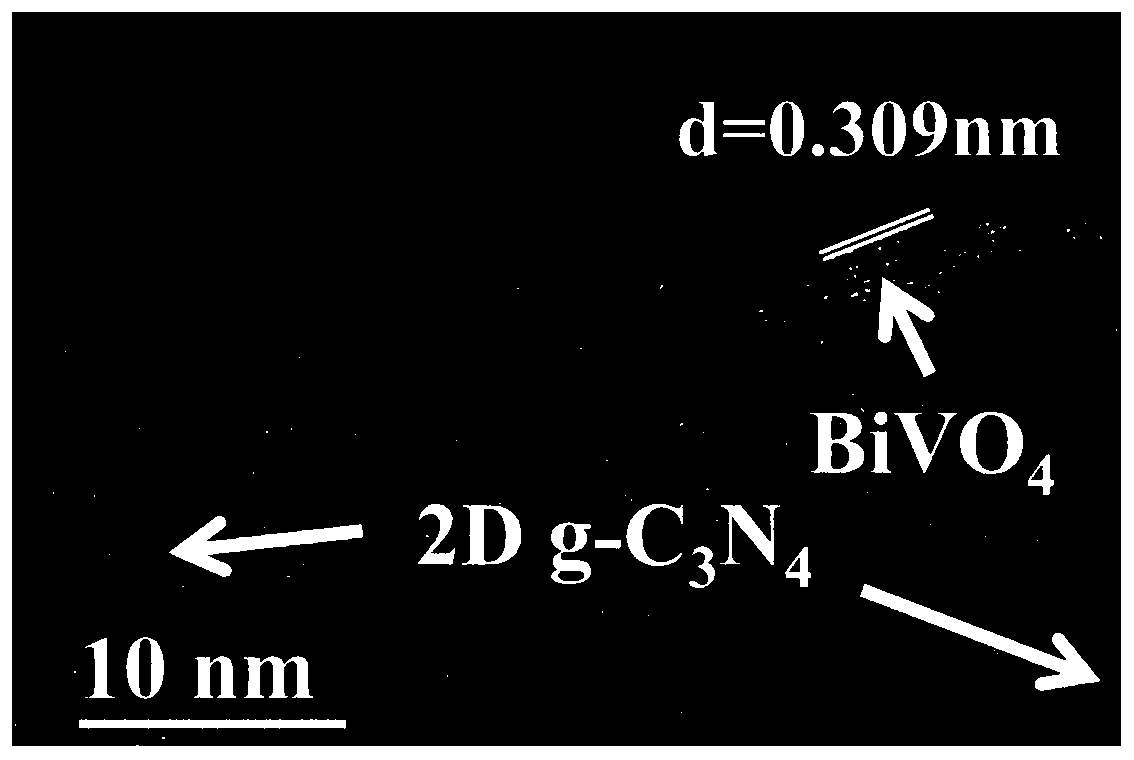

[0031] The invention provides a BiVO 4 / 2D g-C 3 N 4 The preparation method of Z-type heterojunction photocatalyst, first prepare BiVO by hydrothermal reaction method 4 , thermally polymerized melamine to prepare graphitic carbon nitride (g-C 3 N 4 ), 2D g-C was obtained by thermal oxidation exfoliation 3 N 4 , and then BiVO was prepared by ultrasonic-assisted chemical adsorption method using methanol as solvent 4 / 2D g-C 3 N 4 Z type heterojunction photocatalyst, its specific steps are:

[0032] S1. Preparation of BiVO by hydrothermal reaction method 4 :

[0033] With Bi(NO 3 ) 3 ·5H 2 O is a raw material dissolved in HNO with a concentration of 2mol / L 3 solution, fully stirred to form A solution; with NH 4 VO 3 The raw material is dissolved in a NaOH solution with a concentration of 2mol / L, fully stirred to form a B solution; Bi(NO 3 ) 3 ·5H 2 O and NH 4 VO 3 The molar ratio is 1:1; slowly pour solution B into solution A, and keep stirring to form a yell...

Embodiment 1

[0041] S1. Preparation of BiVO by hydrothermal reaction method 4 :

[0042] Weigh 0.58g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) the concentration that dissolves in 10mL is the HNO of 2mol / L 3 solution, A solution was formed after fully stirring for 30 minutes. Weigh 0.14g ammonium metavanadate (NH 4 VO 3 ) was dissolved in 10 mL of NaOH solution with a concentration of 2 mol / L, and stirred thoroughly for 30 min to form B solution. Slowly pour B solution into A solution, and keep stirring to form a yellow mixture suspension, use NaOH solution to adjust the pH value to 7, and then fully stir for 30min, the prepared BiVO 4 Pour the precursor solution into a hydrothermal kettle, tighten and seal the hydrothermal kettle, put it in an oven at 180°C for 12 hours, wait for the reaction kettle to cool down to room temperature, wash the sample with water and ethanol, remove the yellow precipitate in the lower layer, and dry at 80°C for 6 hours to obtain Yellow BiVO 4 sample;

[...

Embodiment 2

[0055] S1. Preparation of BiVO by hydrothermal reaction method 4 :

[0056] Weigh 0.58g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) the concentration that dissolves in 10mL is the HNO of 2mol / L 3 solution, A solution was formed after fully stirring for 30 minutes. Weigh 0.14g ammonium metavanadate (NH 4 VO 3 ) was dissolved in 10 mL of NaOH solution with a concentration of 2 mol / L, and stirred thoroughly for 30 min to form B solution. Slowly pour B solution into A solution, and keep stirring to form a yellow mixture suspension, use NaOH solution to adjust the pH value to 7, and then fully stir for 30min, the prepared BiVO 4 Pour the precursor solution into a hydrothermal kettle, tighten and seal the hydrothermal kettle, put it in an oven at 180°C for 12 hours, wait for the reaction kettle to cool down to room temperature, wash the sample with water and ethanol, remove the yellow precipitate in the lower layer, and dry at 80°C for 6 hours to obtain Yellow BiVO 4 sample;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com