(ZrHfCeTiZn)O2-delta high-entropy oxide ceramic powder and block with fluorite structure and preparation methods

A technology for oxide ceramics and ceramic powders, which is applied in the field of high-performance ceramics, can solve the problems of increasing the surface energy of powders, reducing the sintering temperature of ceramics, and increasing defects, so as to reduce the sintering temperature, have fine grains, and enrich ceramic materials. effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A fluorite-type structure (ZrHfCeTiZn)O 2 The preparation method of -δ high entropy oxide ceramic powder and block, its specific steps and process parameters are as follows:

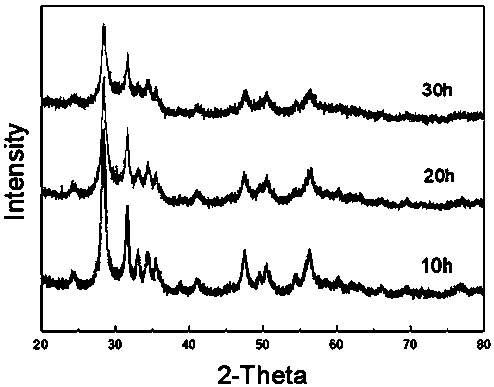

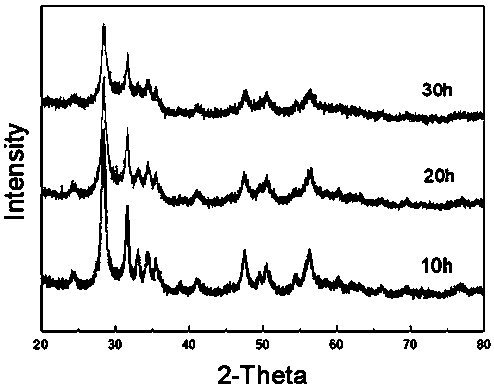

[0029] Step 1, preparation of amorphous ceramic powder: weighing five kinds of ZrO powders in equimolar ratio 2 , HfO 2 , CeO 2 、TiO 2 , ZnO, put the powder into an agate ball mill jar, the selected ball-to-material ratio is 12:1, the speed is 500r / min, every 30min of ball milling is intermittent for 10min, and a total of 30h of ball milling is obtained to obtain an amorphous ceramic powder with uniform composition .

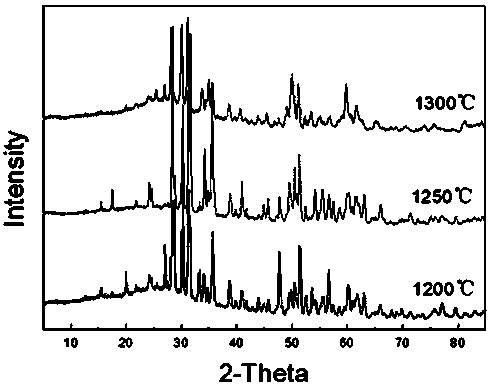

[0030] Step 2. Preparation of high-entropy oxide ceramic powder: heat-treat the amorphous ceramic powder obtained in step 1 at 1100°C for 60 minutes to obtain (ZrHfCeTiZn)O 2 -δ crystalline high-entropy oxide ceramic powder.

Embodiment 2

[0032] The amorphous ceramic powder in step 1 in Example 1 is prepared into a high-entropy oxide ceramic block: the amorphous ceramic powder is packed into a graphite mold, and the graphite mold is sealed, and then the mold is placed in a discharge Sintering in a plasma furnace to obtain (ZrHfCeTiZn)O with a fluorite structure 2 - Delta bulk ceramics.

Embodiment 3

[0034] Prepare the crystalline high-entropy oxide ceramic powder obtained in step 2 of Example 1 into a high-entropy oxide ceramic block: put the crystalline high-entropy oxide ceramic powder into a graphite mold, and seal the graphite mold , and then the mold was placed in a discharge plasma furnace for sintering to obtain (ZrHfCeTiZn)O 2 - Delta bulk ceramics.

[0035] The sintering process of described embodiment 2 and embodiment 3 is as follows:

[0036] Sintering equipment: discharge plasma sintering furnace;

[0037] Heating method: AC pulse current;

[0038] Sintering temperature: 1600°C;

[0039]Sintering time: 5min;

[0040] Sintering pressure: 30MPa;

[0041] Heating rate: 50°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com