A quantum dot film, a preparation method thereof and a QLED device

A technology of quantum dots and quantum dot solution, applied in the field of quantum dots, to achieve the effects of easy repetition, improved fluorescence intensity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

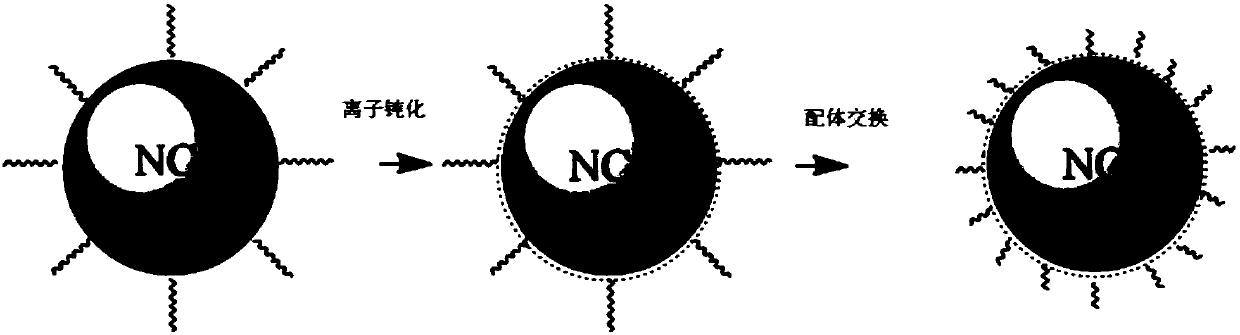

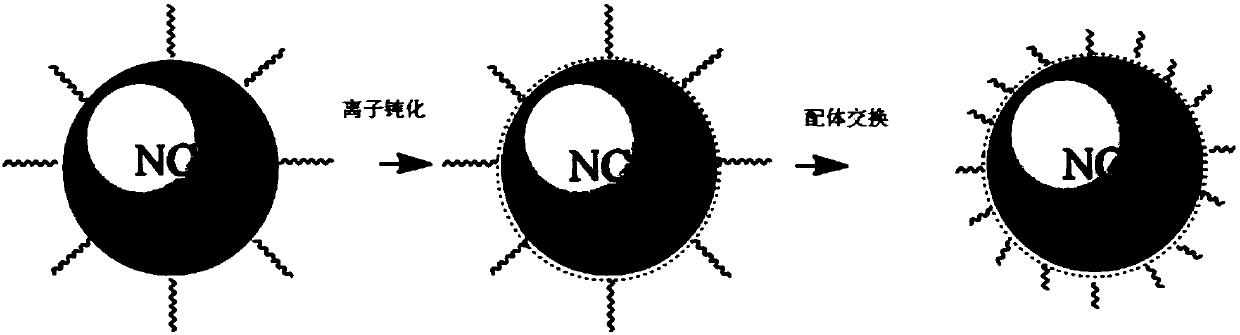

[0021] Correspondingly, a kind of preparation method of quantum dot thin film comprises the following steps:

[0022] S01: providing a first quantum dot solution, the first quantum dot solution contains quantum dots with initial ligands bound to their surfaces;

[0023] S02: providing an anion precursor, adding the anion precursor to the first quantum dot solution, and performing passivation treatment to obtain a second quantum dot solution;

[0024] S03: providing a thiol ligand, adding the thiol ligand to the second quantum dot solution, performing surface ligand exchange, and obtaining a third quantum dot solution;

[0025] S04: Depositing the third quantum dot solution on a substrate to obtain the quantum dot film.

[0026] The preparation method of the quantum dot thin film provided by the embodiment of the present invention firstly adds an appropriate amount of anion precursor to the quantum dot mixed solution to passivate the passivated quantum dot, so that the surface...

Embodiment 1

[0038] The preparation method of PbS quantum dots, comprises the steps:

[0039] 1) Lead oleate {Pb(OA) 2} Preparation of precursors:

[0040] Take 0.6mmol of lead acetate trihydrate, 2ml of oleic acid (OA), and 10mL of octadecene (ODE) into a three-necked flask, first ventilate at room temperature for 20min, then raise the temperature to 150°C and stir for 30min, then lower the temperature to 120°C.

[0041] 2) Preparation of sulfur (S) precursor:

[0042] Add 4mmol of S to 6ml of trioctylphosphine (TOP), heat to 170°C for 30min, then cool down to 140°C.

[0043] 3) After raising the temperature of the mixture in 1) to 150°C, take 2mL of sulfur precursor and quickly inject it into the flask to react for 10 minutes, quickly take out the heating mantle and wait for the temperature of the mixture to cool down to room temperature, then add the extractant and precipitate The solvent is centrifuged and cleaned to obtain oil-soluble PbS near-infrared quantum dots and dried, and t...

Embodiment 2

[0045] The preparation method of S-TOP passivation PbS quantum dots, comprises the steps:

[0046] 1) get the PbS quantum dot solution (quantum dot weight is 100mg) in the above-mentioned embodiment 1 and be dispersed in the 18 dilute solution of 10mL, carry out normal temperature exhaust 20min first under inert gas, then the PbS quantum dot solution temperature is raised to 150°C.

[0047] 2) Disperse 0.5 mmol of sulfur (S) powder in 1 mL of trioctyl phosphine (TOP) and dissolve at 170°C to obtain an anion precursor S-TOP solution, then cool to room temperature for use.

[0048] 3) Add the S-TOP solution in 2) to the quantum dot solution in 1) for passivation for 30 minutes, and then reduce the temperature of the mixed solution to 100° C. to maintain a constant temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com