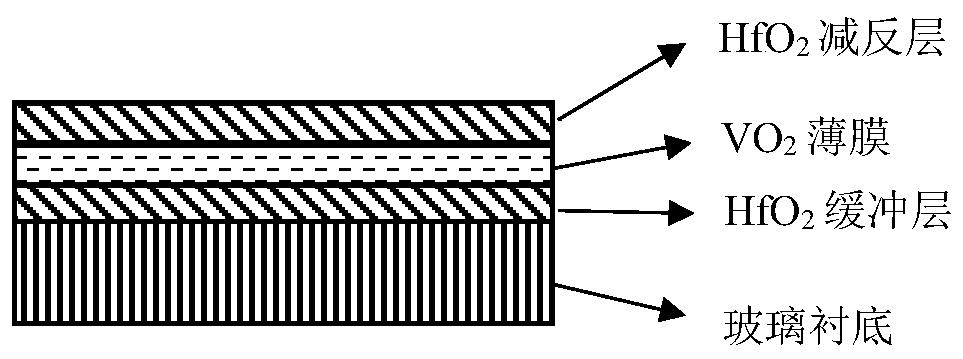

HfO2/VO2/HfO2 sandwich structure intelligent window film and preparation method thereof

A smart window, sandwich technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of high cost, achieve improved crystal quality, enhanced visible light transmittance, and excellent thermal diffusion barrier performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

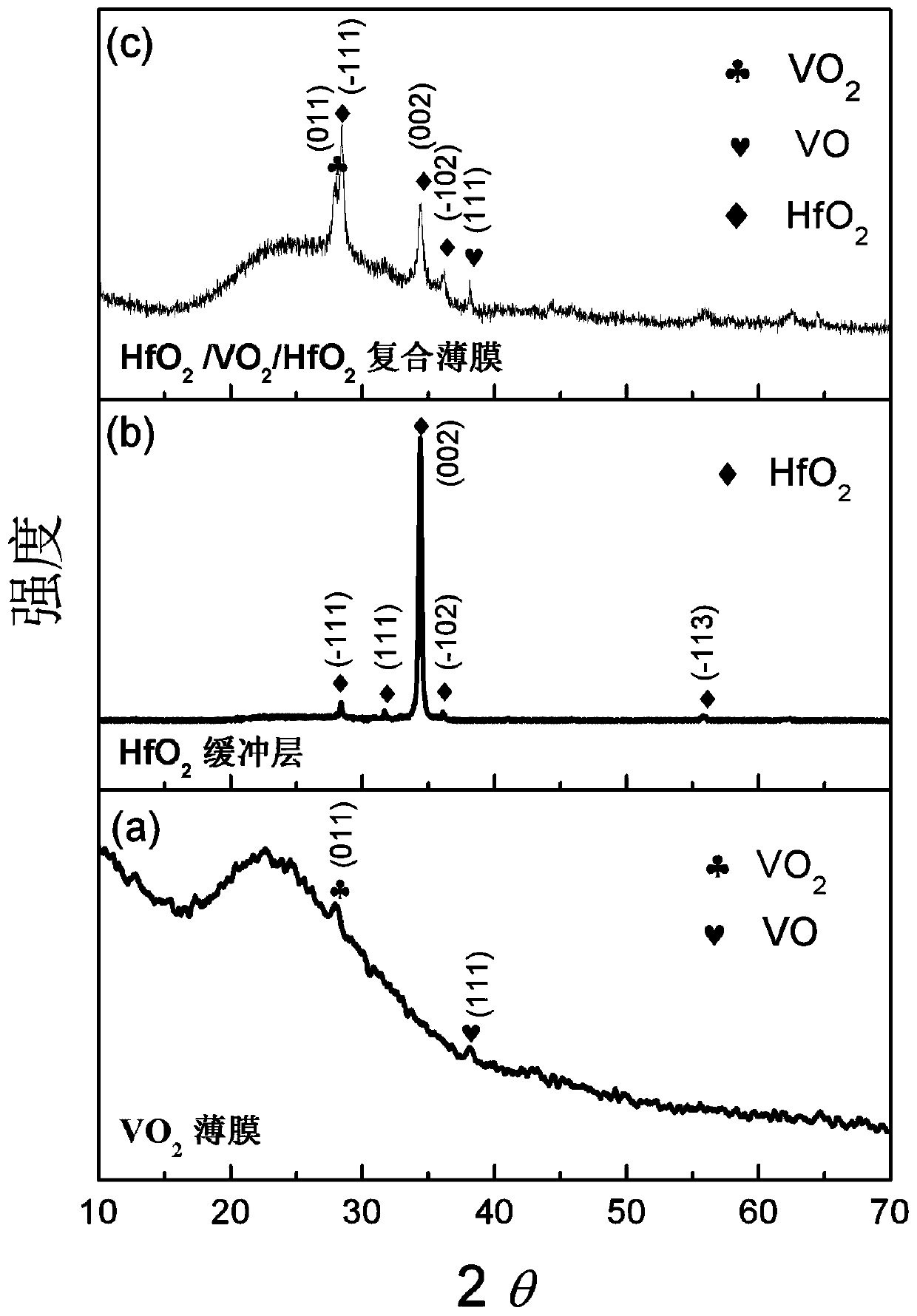

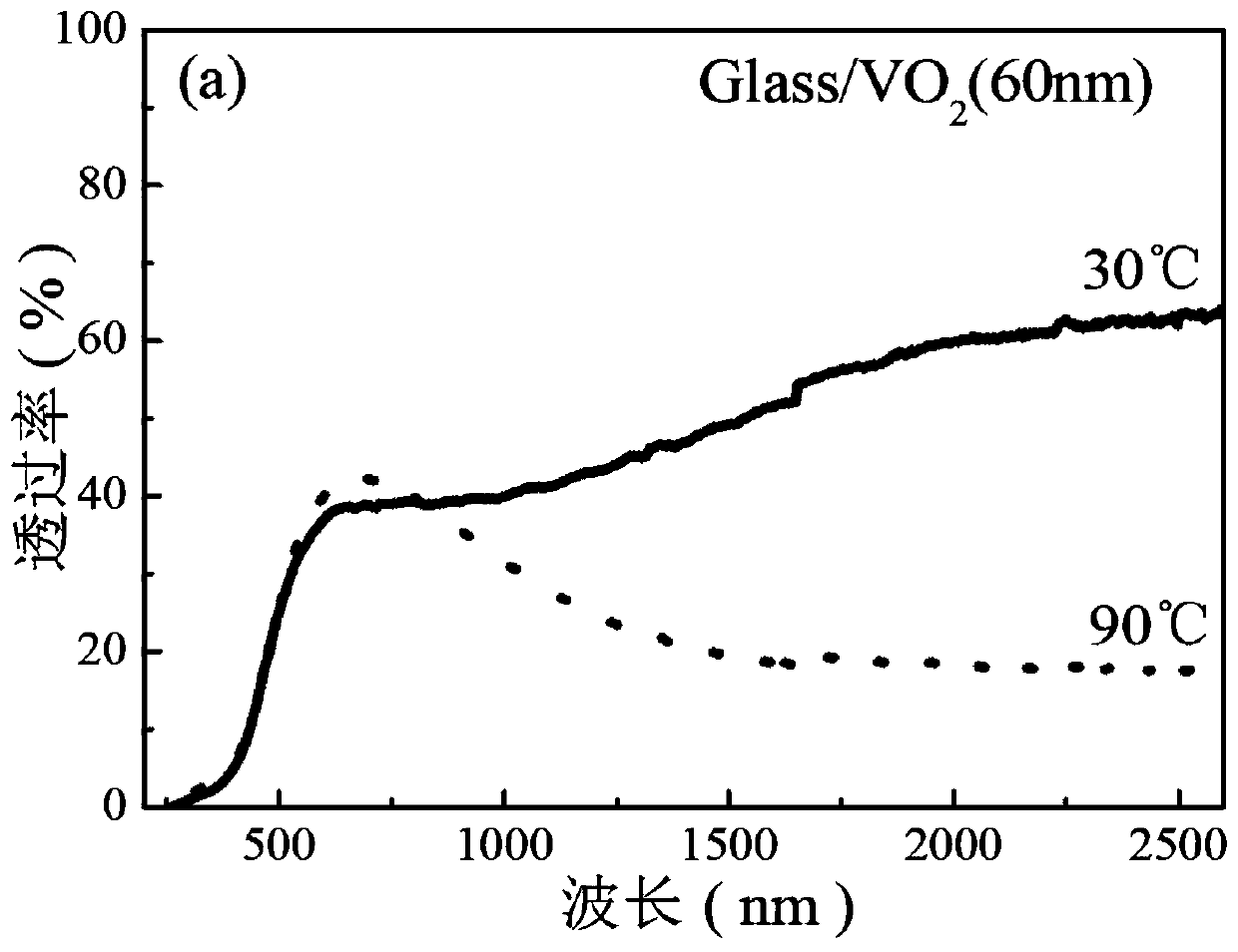

[0029] HfO 2 / VO 2 / HfO 2 A method for preparing a sandwich-structure smart window film, comprising the steps of:

[0030] Step 1: Put the alkali-free glass into acetone, absolute ethanol, and deionized water in sequence, wash it with KQ-50B ultrasonic instrument for 10 minutes, and then dry it with nitrogen;

[0031] Step 2: Before deposition, vacuumize the back to 5.0×10 -4 Pa, deposit the first layer of HfO under the condition of 200℃~250℃ substrate temperature and 0.2Pa~0.4Pa oxygen pressure 2 buffer layer, then raise the substrate temperature to 500°C-550°C and adjust the oxygen pressure to 0.9Pa-1.3Pa, deposit VO 2 thin film (grown VO 2 The laser energy is set to 200mJ and the frequency is 2Hz for the thin film); then the substrate temperature is lowered to room temperature, and the oxygen pressure is lowered to 0Pa at the same time, and the deposition of HfO 2 AR layer (deposited HfO 2 When the anti-reflection layer, the laser energy is set to 200mJ, and the freq...

Embodiment

[0034] HfO 2 / VO 2 / HfO 2 The preparation method of the sandwich structure intelligent window film, the steps are as follows:

[0035] Step 1: First put the alkali-free glass into a beaker filled with acetone, absolute ethanol, and deionized water in sequence, clean it with KQ-50B ultrasonic instrument for 10 minutes, and then dry it with nitrogen;

[0036] Step 2: Before deposition, vacuumize the back to 5.0×10 -4 Pa, the first layer of HfO was deposited at a substrate temperature of 200°C and an oxygen pressure of 0.2Pa 2 buffer layer, then raise the substrate temperature to 550°C and adjust the oxygen pressure to 0.9Pa, deposit VO 2 thin film (grown VO 2 The laser energy is set to 200mJ and the frequency is 2Hz for the thin film); then the substrate temperature is lowered to room temperature, and the oxygen pressure is lowered to 0Pa at the same time, and the deposition of HfO 2 AR layer (deposited HfO 2 When the anti-reflection layer, the laser energy is set to 200m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com