Aerogel composite glass and manufacturing method thereof

A technology combining glass and manufacturing methods, which is applied in the fields of light transmission, heat preservation, lighting, sound insulation materials, and heat insulation, and can solve problems such as high cost, difficulty in market promotion, and difficulty in airgel preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

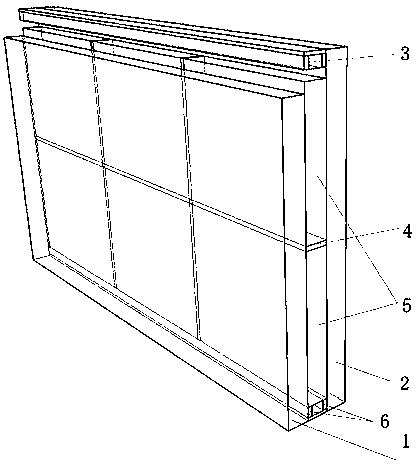

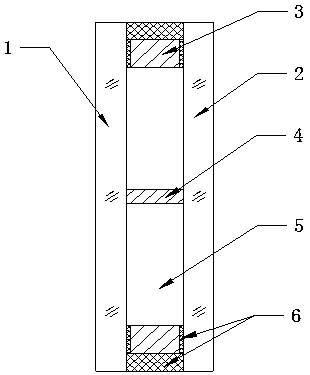

[0108] Use the following steps to prepare aerogel composite glass:

[0109] (1) Use an adhesive to bond the butadiene rubber strip 42 with a thickness of 2mm on the inner surface of the broken aluminum spacer frame 3 and the two sides of the polycarbonate spacer 41;

[0110] (2) Use water glass sealant 6 to bond the lower surface of the broken aluminum spacer frame 3 to a piece of float glass 2 to form an open cavity with a glass thickness of 6mm and a cavity thickness of 6mm;

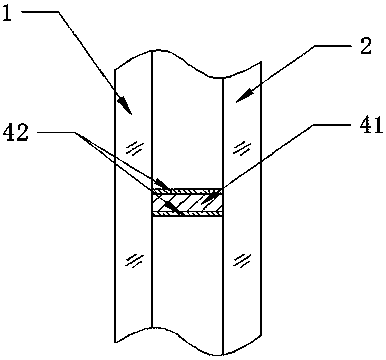

[0111] (3) Follow Figure 4 As shown in the pattern, the end of the polycarbonate spacer 41 is welded and fixed on the inner surface of the broken aluminum spacer frame 3 to form a plurality of isolation cavities;

[0112] (4) Fill each isolation cavity with SiO of corresponding size 2 Aerogel sheet 51;

[0113] (5) Use water glass sealant 6 to bond another piece of float glass 1 to the upper surface of the broken aluminum spacer frame 3, and then use silicone sealant 6 to bond the two pieces of float glass on t...

Embodiment 2

[0116] Use the following steps to prepare aerogel composite glass:

[0117] (1) Use an adhesive to bond the hollow-core ethylene-propylene rubber strip 42 on the inner surface of the stainless steel spacer frame 3, with a thickness of 5mm, and bond the hollow-core benzene on both sides of the polystyrene spacer 41 Ethylene elastomer elastic strip 42 with a thickness of 1mm;

[0118] (2) Use potassium silicate sealant 6 to bond the lower surface of the stainless steel spacer frame 3 to a piece of tempered glass 2 to form an open cavity with a glass thickness of 6mm and a cavity thickness of 8mm;

[0119] (3) Follow Figure 5 In the pattern shown, the end of the polystyrene spacer 41 is welded and fixed on the inner surface of the stainless steel spacer frame 3 to form a plurality of isolation cavities;

[0120] (4) Fill each isolation cavity with regular hexahedron SiO 2 The aerogel particles 52 are vibrated horizontally and vertically at the same time, so that the aerogel particles 52...

Embodiment 3

[0124] Use the following steps to prepare aerogel composite glass:

[0125] (1) Use butyl sealant 6 to bond the lower surface of the glass fiber reinforced plastic spacer frame 3 to a piece of cesium potassium glass 2 to form an open cavity. The inner surface of the spacer frame 3 is glued with a thickness of 8mm The silicone elastomer elastic strip 42 has a glass thickness of 6mm and a cavity thickness of 10mm;

[0126] (2) Follow Image 6 In the pattern shown, the end of the silicone elastomer buffer spacer 4 with a thickness of 2 mm is fixed on the inner surface of the glass fiber reinforced plastic spacer frame 3 to form a plurality of isolation cavities;

[0127] (3) Fill the upper part of the isolation cavity with regular octahedral SiO 2 The aerogel particles 52 are vibrated horizontally and vertically at the same time, so that the aerogel particles 52 are dense in the isolation cavity, and then the isolation cavity of the lower half is filled with SiO of the corresponding siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com