Sludge side-stream treatment device based on nitrite reinforced sludge fermentation and method thereof

A technology of nitrite and sludge backflow, applied in the field of urban sewage treatment and recycling, can solve problems such as fluctuations in influent water quality, and achieve the effects of increasing bacterial concentration, speeding up speed, and increasing sludge reduction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

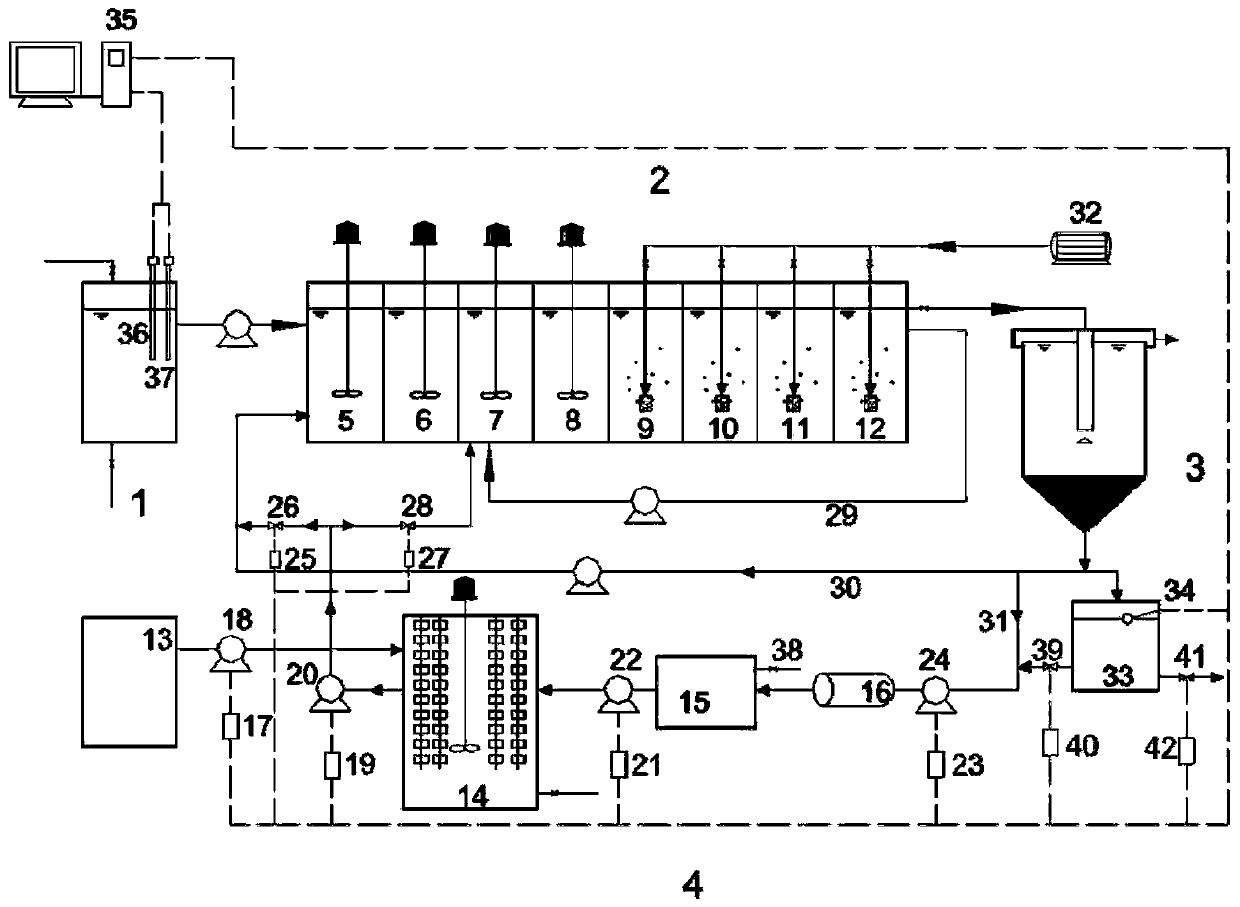

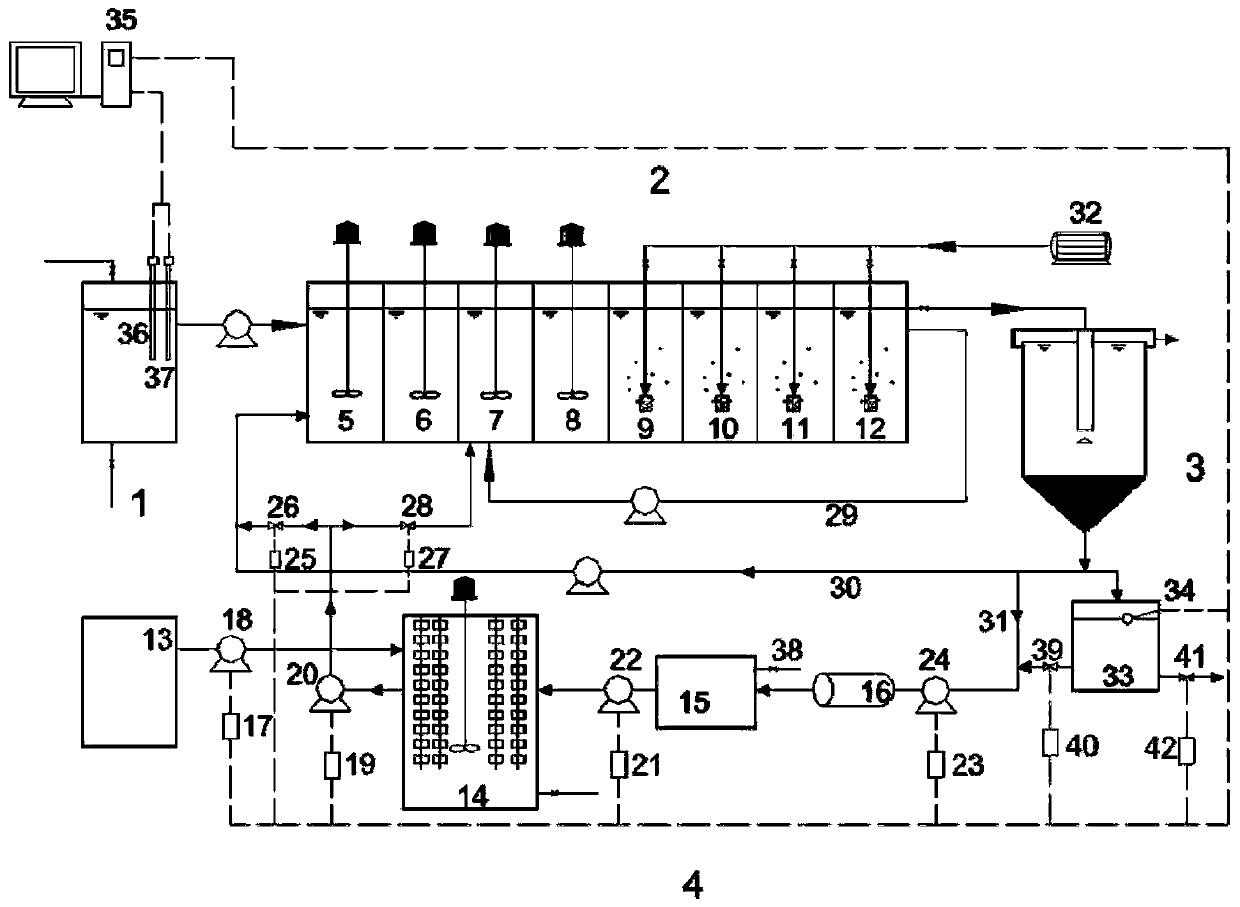

[0017] The raw water inflow is monitored by the PLC control system (35) and the C / N ratio is 3.6. The raw water is treated by the AAO continuous flow reactor (2) and then enters the sedimentation tank (3). The remaining sludge in the rear sedimentation tank (3) passes through the sludge The concentration of the mud side reflux system (4) removes 40% of the water and then enters the sludge digestion tank (14) for digestion. The digestion time is 1 day, and at the same time, the sludge is digested through the nitrite solution storage tank (13). The nitrite solution is continuously added to the tank (14), and the temperature of the digestion tank is 30°C. After the digestion is completed, the digested sludge rich in organic matter is returned to the anoxic zone I (7) to supplement carbon sources and promote denitrification. Nitrogen action.

Embodiment 2

[0019] The raw water inflow is monitored by the PLC control system (35) and the C / N ratio is 7.8. The raw water is treated by the AAO continuous flow reactor (2) and then enters the sedimentation tank (3). The remaining sludge in the rear sedimentation tank (3) passes through the sludge The concentration of the mud side reflux system (4) removes 30% of the water and then enters the sludge digestion tank (14) for digestion. The digestion time is 5 days. Continuously add nitrite solution to the tank (14), the temperature of the digestion tank is 30°C, the sludge after digestion is relatively stable, and returns to the anaerobic zone I (7) to supplement the activated sludge concentration in the anaerobic zone .

Embodiment 3

[0021] The raw water inflow is monitored by the PLC control system (35) and the C / N ratio is 12.5. The raw water is treated by the AAO continuous flow reactor (2) and then enters the sedimentation tank (3). The remaining sludge in the rear sedimentation tank (3) passes through the sludge After the concentration of the mud side reflux system (4) removes 50% of the water, it enters the sludge digestion tank (14) for digestion, and the digestion time is 10 days. At the same time, the nitrite solution storage tank (13) feeds the sludge digestion tank In (14), nitrite solution is continuously added, the temperature of the digestion tank is 35°C, the sludge after digestion is significantly reduced, and its properties are stable. While supplementing the sludge concentration, the effect of in-situ sludge reduction is enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com