Process for purifying coke oven gas and recycling high-quality stronger ammonia water and sulfur

A coke oven gas and concentrated ammonia water technology, which is applied in combustible gas purification, combustible gas purification/transformation, chemical industry, etc., can solve the problems of difficult treatment of desulfurization waste liquid and low-quality sulfur paste, generation of precipitation, and high equipment investment. Achieve the effect of meeting green chemical production, reducing biochemical treatment costs, and stable system operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

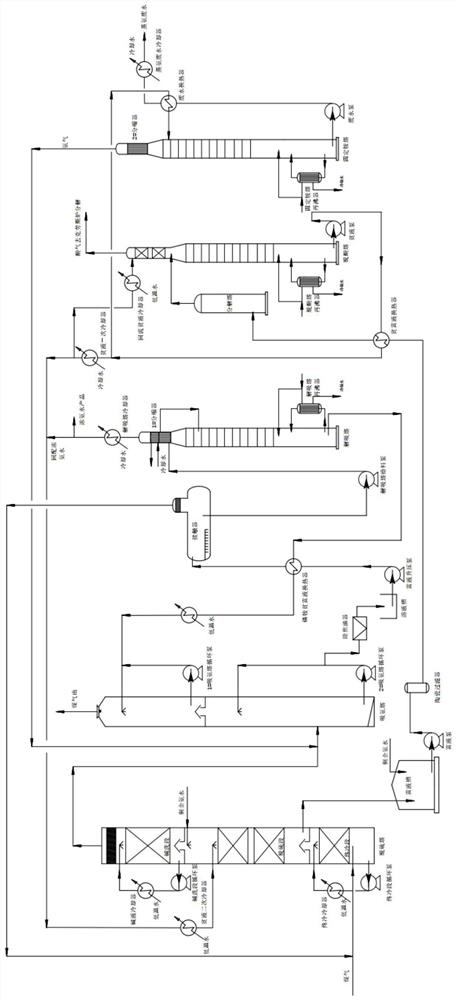

[0020] The present invention will be further described below with reference to the accompanying drawings and specific embodiments. These embodiments should be understood as only for illustrating the present invention and not for limiting the protection scope of the present invention. After reading the contents described in the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent changes and modifications also fall within the scope defined by the claims of the present invention.

[0021] like figure 1 As shown, it is a special process flow diagram of a process for purifying and recycling high-quality concentrated ammonia and sulfur provided by a preferred embodiment of the present invention.

[0022] like figure 1 As shown, the gas compressed by the blower (containing H 2 S:5-9g / m 3 , NH 3 :3-7g / m 3 ), first enter the final cooling section at the lower part of the desulfurization tower, and be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com