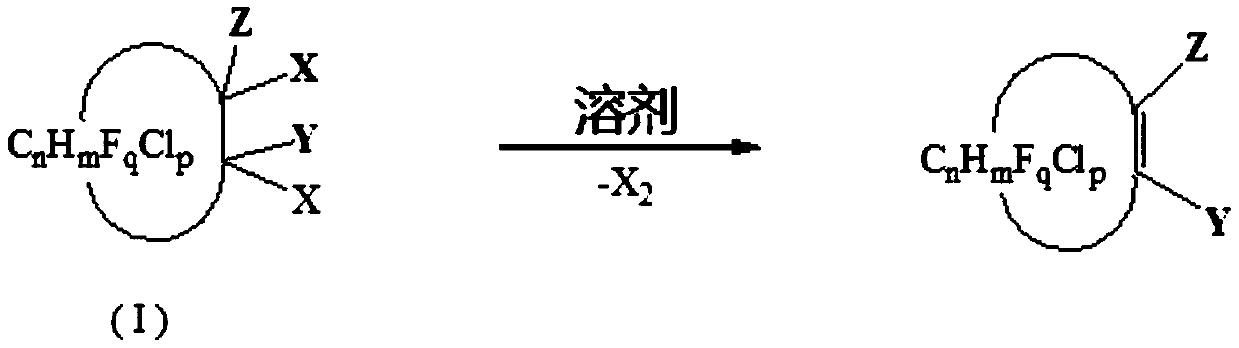

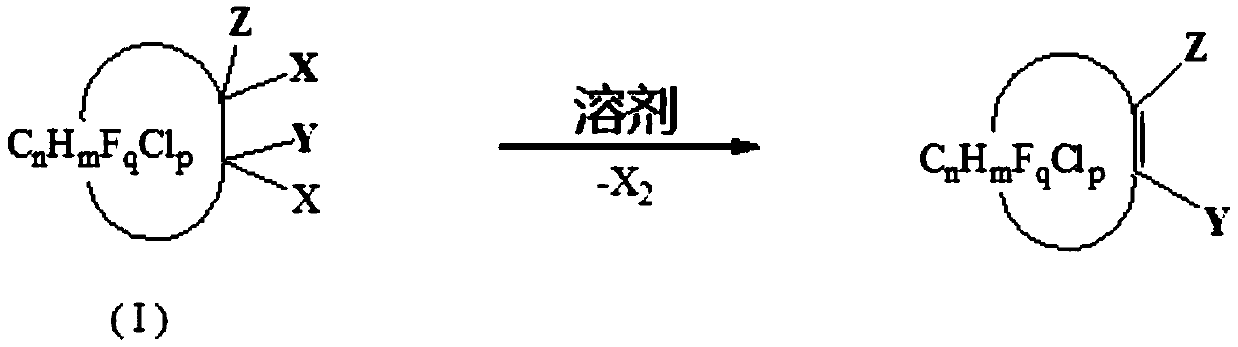

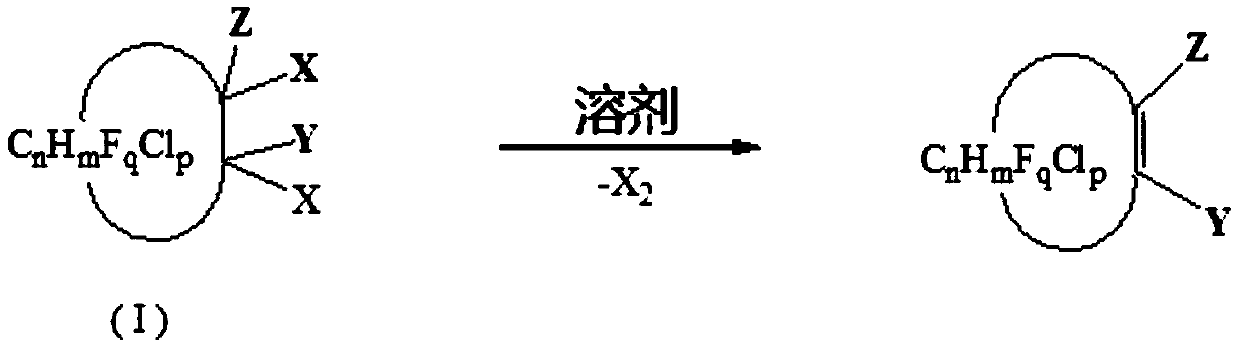

Preparation method of halogenation cycloolefin

A technology of halogenated cycloalkenes and halogenated cycloalkanes, which is applied in the field of preparation of halogenated cycloalkenes, can solve the problems of waste solids such as a large amount of metal halides, pollute the environment, and low yield, and achieve high yield and safe process Reliable results with mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In a 1L autoclave, add 2 mol of N,N-dimethylformamide and 1 mol of 1,2-dichlorohexafluorocyclobutane (the molar ratio of cis and trans is 60:40), at 160 The reaction was carried out for 6 hours. After the reaction was finished, rectification was carried out to obtain hexafluorocyclobutene (boiling point was 5-6°C / 760mmHg), the yield was 96.8%, and the purity was 99.1%.

Embodiment 2

[0057] In a 1L autoclave, add 2 mol of N,N-dimethylacetamide and 1 mol of 1,2-dichlorohexafluorocyclobutane (the molar ratio of cis and trans is 60:40), at 170 The reaction was carried out for 6 hours. After the reaction was finished, rectification was carried out to obtain hexafluorocyclobutene (boiling point was 5-6°C / 760mmHg), the yield was 95.8%, and the purity was 99.2%.

Embodiment 3

[0059] In a 1L autoclave, add 1 mol of N,N-dimethylformamide and 1 mol of 1,1,2-trichloro-2,3,3-trifluorocyclobutane, and react at 160 degrees for 6 hours, After the reaction, rectification was carried out to obtain 1-chloro-2,3,3-trifluorocyclobutene (boiling point: 51-52°C / 760mmHg), with a yield of 80.5% and a purity of 98.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com