High-hydrophobicity low-odor flame-retardant polypropylene composite material and preparation method thereof

A technology of flame-retardant polypropylene and composite materials, applied in the field of composite materials, can solve the problems of high technical difficulty, high cost, and difficulty in meeting industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

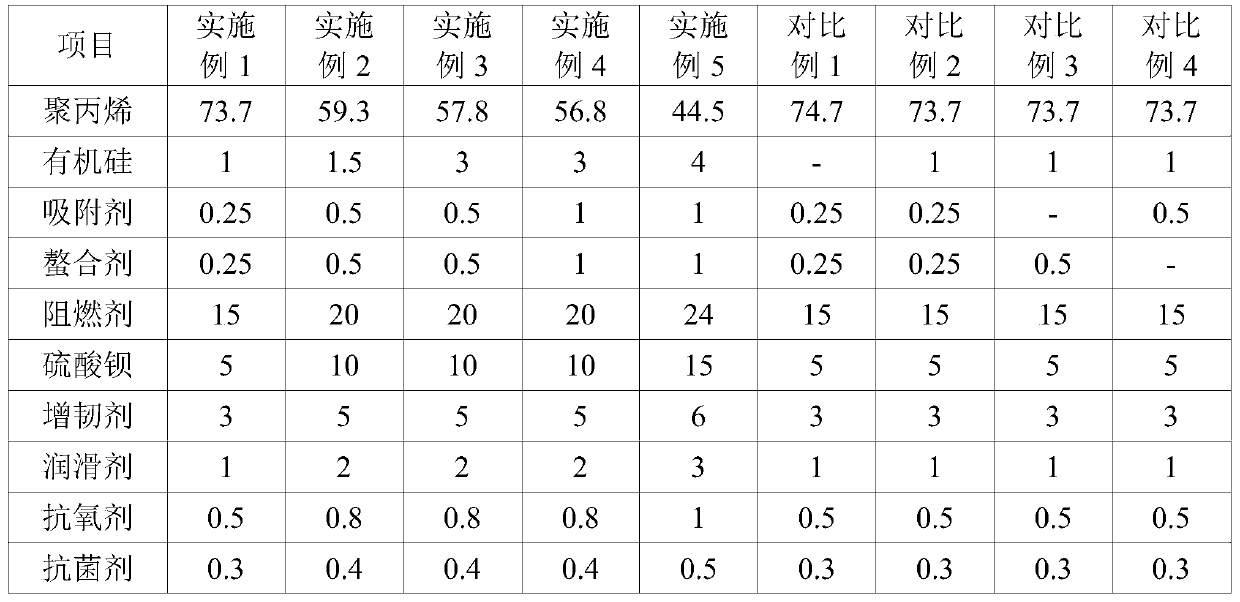

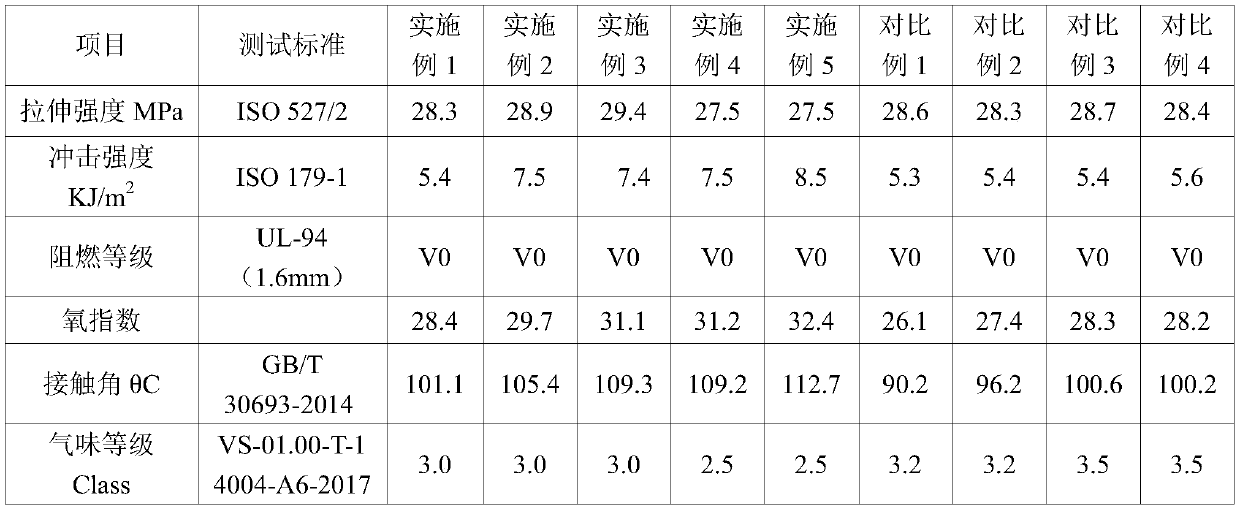

Embodiment 1

[0039] According to the ratio in Table 1, polypropylene and barium sulfate, toughening agent, flame retardant, fluorine-containing silicone, antioxidant, antibacterial agent (nano-zinc oxide), adsorbent (nano-zinc oxide), chelating agent (ricorbium oxide) Sesame oil zinc), lubricant are joined in the high-speed mixing pot successively and mix 3 minutes, obtain compound.

[0040] The compound is added to the main feeding port of the twin-screw extruder, the speed of the twin-screw extruder is set to 250rpm, and the temperature from the feeding section of the extruder to the head is set to 160°C and 170°C respectively , 180°C, 185°C, 185°C, 200°C, 200°C, 185°C, 180°C, the mixture was extruded, cooled, and granulated to obtain a highly hydrophobic and low-odor flame-retardant polypropylene composite material, and its properties are shown in the table 2.

Embodiment 2

[0042] Polypropylene and barium sulfate, toughener, flame retardant, fluorine-containing silicone, antioxidant, antibacterial agent (nano-silver oxide), adsorbent (titanium dioxide), chelating agent (hyperbranched poly Ether modified chelating agent, (9Z,12R)-12-hydroxyl-9-octadecenoic acid zinc salt) and lubricant were sequentially added into a high-speed mixing pot and mixed for 3 minutes to obtain a mixture.

[0043] The compound is added to the main feeding port of the twin-screw extruder, the speed of the twin-screw extruder is set to 350rpm, and the temperature from the feeding section of the extruder to the head is set to 170°C and 175°C respectively , 175°C, 185°C, 185°C, 190°C, 190°C, 180°C, 175°C, the mixture was extruded, cooled, and granulated to obtain a highly hydrophobic and low-odor flame-retardant polypropylene composite material, and its properties are shown in the table 2.

Embodiment 3

[0045] Polypropylene and barium sulfate, toughening agent, flame retardant, fluorine-containing silicone, antioxidant, antibacterial agent (N-(trichloromethylthio) phthalimide) were mixed according to the ratio in Table 1 , adsorbent (porous aluminum-silicon inorganic substance), chelating agent (hyperbranched polyether modified chelating agent, (9Z,12R)-12-hydroxy-9-octadecenoic acid zinc salt), and lubricant were added to the high-speed mixer in sequence Mix in the material pot for 3 minutes to obtain the mixture.

[0046] The compound is added to the main feeding port of the twin-screw extruder, the speed of the twin-screw extruder is set to 400pm, and the temperature from the feeding section of the extruder to the head is set to 170°C and 180°C respectively , 180°C, 185°C, 185°C, 185°C, 190°C, 180°C, 175°C, the mixture was extruded, cooled, and granulated to obtain a highly hydrophobic and low-odor flame-retardant polypropylene composite material, and its properties are sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com