Production apparatus and method for iron making

A production device and one-way technology, applied in the fields of metallurgy and chemical production, can solve the problems of ineffective utilization of waste heat, excessive heat dissipation, affecting the quality of reduced iron making, etc., achieve a green and environmentally friendly production method, improve thermal energy utilization, and reduce coal consumption. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

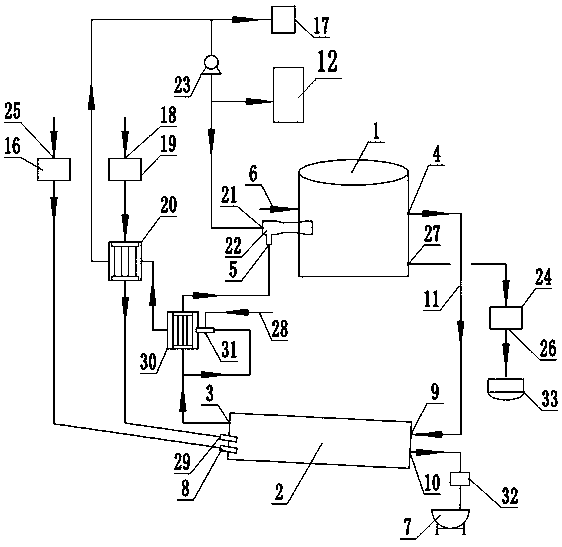

[0022] The ironmaking production device of the present invention is as figure 1 As shown, it includes rotary kiln 2, gasification heating furnace 1, coke powder bin 16, product transport vehicle 7, tail gas heater 30, iron fine powder preheater 20 and CO2 Recovery unit 17. The rotary kiln is equipped with an exhaust gas outlet 3, a coke powder inlet 8, a raw material nozzle 29, a circulating CO inlet 9 and a product outlet 10, the product outlet 10 is connected to the product transport vehicle 7 through a molten iron waste heat recovery device 32, and the coke powder bin 16 is provided with a coke powder inlet 25 , Iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com