Coated foam vibration-damping sheet specially used for automotive door and preparation method of vibration-damping sheet

A special bag, car door technology, applied in the field of damping materials, can solve the problems of rising fuel consumption and emissions, failing to achieve green environmental protection, increasing body weight, etc., to achieve improved bending resistance, high and low temperature resistance, and improved water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

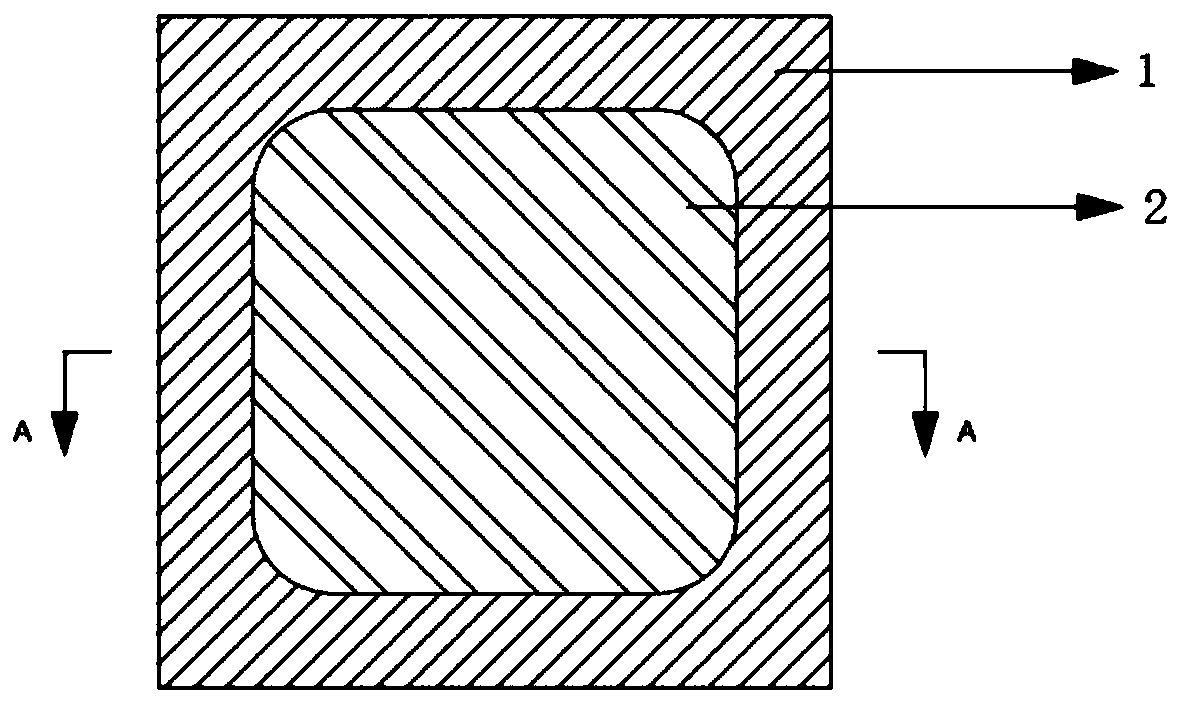

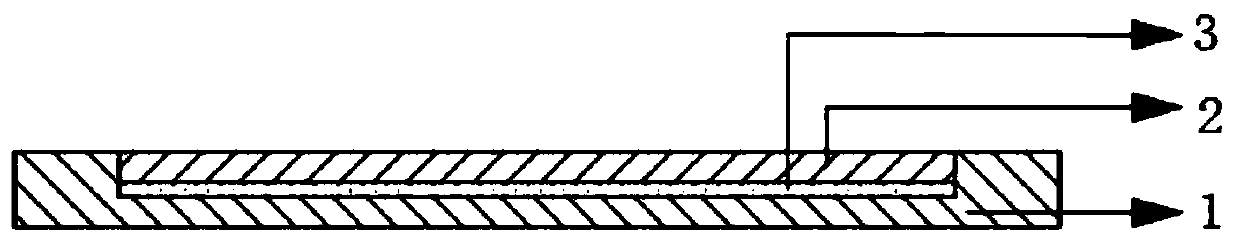

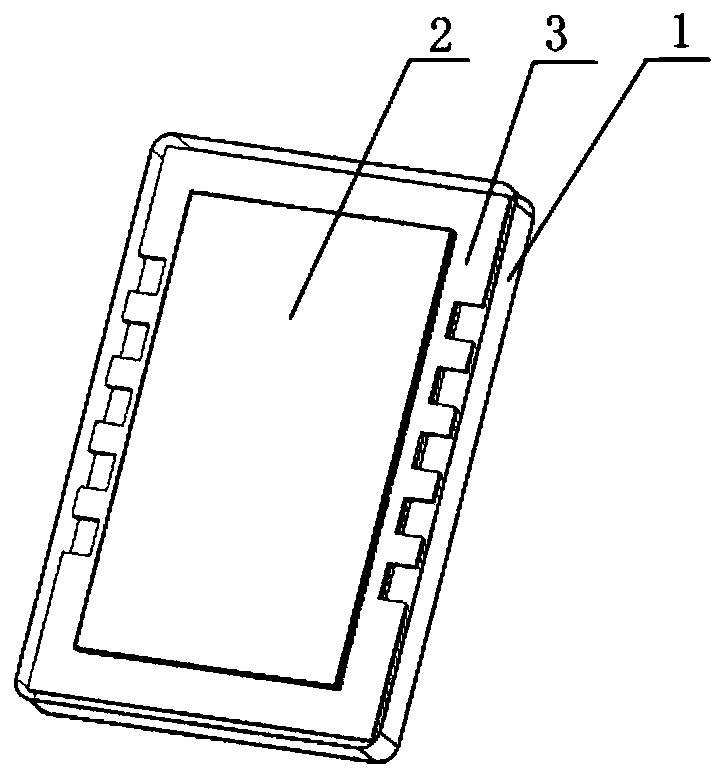

Image

Examples

Embodiment 1

[0041] A kind of damping layer in the coated foam damping sheet specially used for automobile door, including the following raw materials butyl rubber 100kg, N550 carbon black 40kg, polyisobutylene PIB-130050kg, petroleum resin EScorez 120450kg, graphite 5 kg of olefin-coated hollow glass microspheres, 150 kg of light calcium carbonate, and 6 kg of naphthenic oil.

[0042] In terms of parts by mass, the coated foam layer includes the following raw materials: 100kg of EVA resin, 20kg of foaming agent OBSH, 1kg of high-activity magnesium oxide as an acid neutralizer, 1kg of crosslinking agent DCP, 0.1kg of calcium carbonate, and 0.1kg of phthalocyanine green.

[0043] The preparation method of the damping layer comprises: (1) plasticizing the butyl rubber on an open mill for 8 minutes at a temperature of 70° C.; (2) putting the butyl rubber obtained in step (1) into the internal mixer, Put in carbon black, light calcium carbonate, and graphene-coated hollow glass microspheres, k...

Embodiment 2

[0049]A kind of damping layer in the coated foam damping plate specially used for automobile door, which includes the following raw materials butyl rubber 100kg, N550 carbon black 60kg, polyisobutylene PIB-130080kg, petroleum resin EScorez 120460kg, graphite Alkene-coated hollow glass microspheres 8kg, light calcium carbonate 180kg, naphthenic oil 15kg.

[0050] In terms of parts by mass, the coated foam layer includes the following raw materials: 100 kg of EVA resin, 25 kg of foaming agent OBSH, 2 kg of acid neutralizing agent highly active magnesium oxide, 3 kg of crosslinking agent DCP, 3 kg of talcum powder, and 0.2 kg of phthalocyanine green.

[0051] The preparation method of the damping layer comprises: (1) plasticizing and mixing butyl rubber on an open mill for 10 minutes at a temperature of 80° C.; (2) putting the butyl rubber obtained in step (1) into an internal mixer, Put in carbon black, light calcium carbonate, and graphene-coated hollow glass microspheres, knea...

Embodiment 3

[0056] A kind of damping layer in the coated foam damping plate specially used for automobile door, including the following raw materials butyl rubber 100kg, N550 carbon black 45kg, polyisobutylene PIB-130065kg, petroleum resin EScorez 130453kg, graphite Alkene-coated hollow glass microspheres 7kg, light calcium carbonate 160kg, naphthenic oil 8kg.

[0057] In terms of parts by mass, the coated foam layer includes the following raw materials EVA resin 100kg, foaming agent OBSH22kg, acid neutralizer high active magnesium oxide 1.3kg, crosslinking agent DCP1.5kg, calcium carbonate 2kg, phthalocyanine green 0.15kg kg.

[0058] The preparation method of the damping layer includes: (1) plasticizing the butyl rubber on an open mill for 9 minutes at a temperature of 75° C.; (2) putting the butyl rubber obtained in step (1) into the internal mixer, Put in carbon black, light calcium carbonate, and graphene-coated hollow glass microspheres, knead at 70-80°C for 6 minutes, then add pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com