Carbon-based material and preparation method thereof

A carbon-based material and matrix technology, applied in the field of carbon-based materials and their preparation, can solve the problems of increasing the cost and complexity of a photothermal system, unfavorable to industrialized production, and large surface heat loss, achieving high-efficiency seawater desalination and reducing preparation costs. , Efficient use of efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

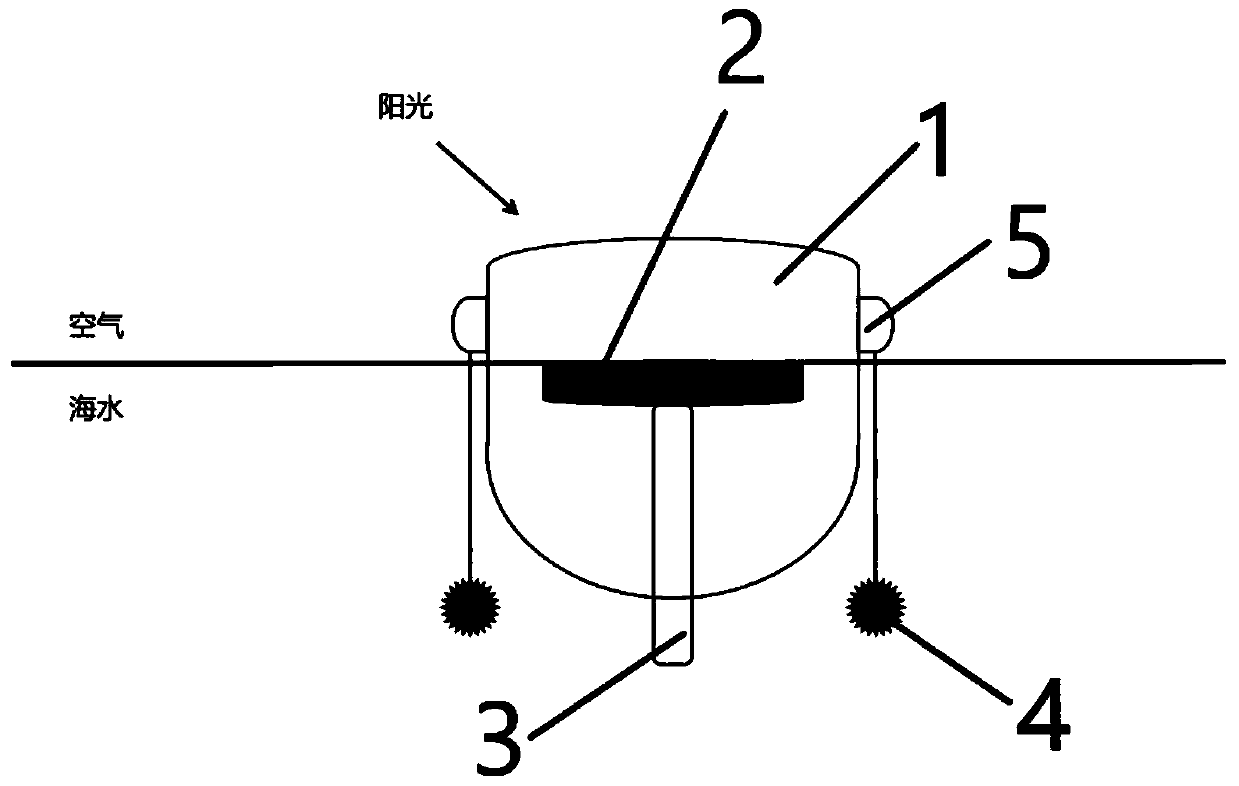

[0040] Such as figure 1 Shown, the preparation method of a kind of carbon-based material provided by the present invention comprises the following steps:

[0041] Step 1, mixing starch and water according to the mass percentage of 1: (1-1.5) to obtain preliminary materials;

[0042] Step 2, freeze-drying the obtained preliminary material at -50 to -70°C for 20 to 50 hours to obtain a preform;

[0043] Step 3, performing high-temperature carbonization on the preform obtained in step 2 to make a carbon foam matrix;

[0044] Step 4: Soak the carbon foam matrix prepared in step 3 in the dopamine solution, and then dry at room temperature to obtain the dopamine-deposited carbon foam matrix.

[0045] Further, in step 1, yeast is added to starch and water, wherein the mass percentage of starch, yeast and water is 1:1: (2-2.5), which is used to increase the adhesiveness of starch and water.

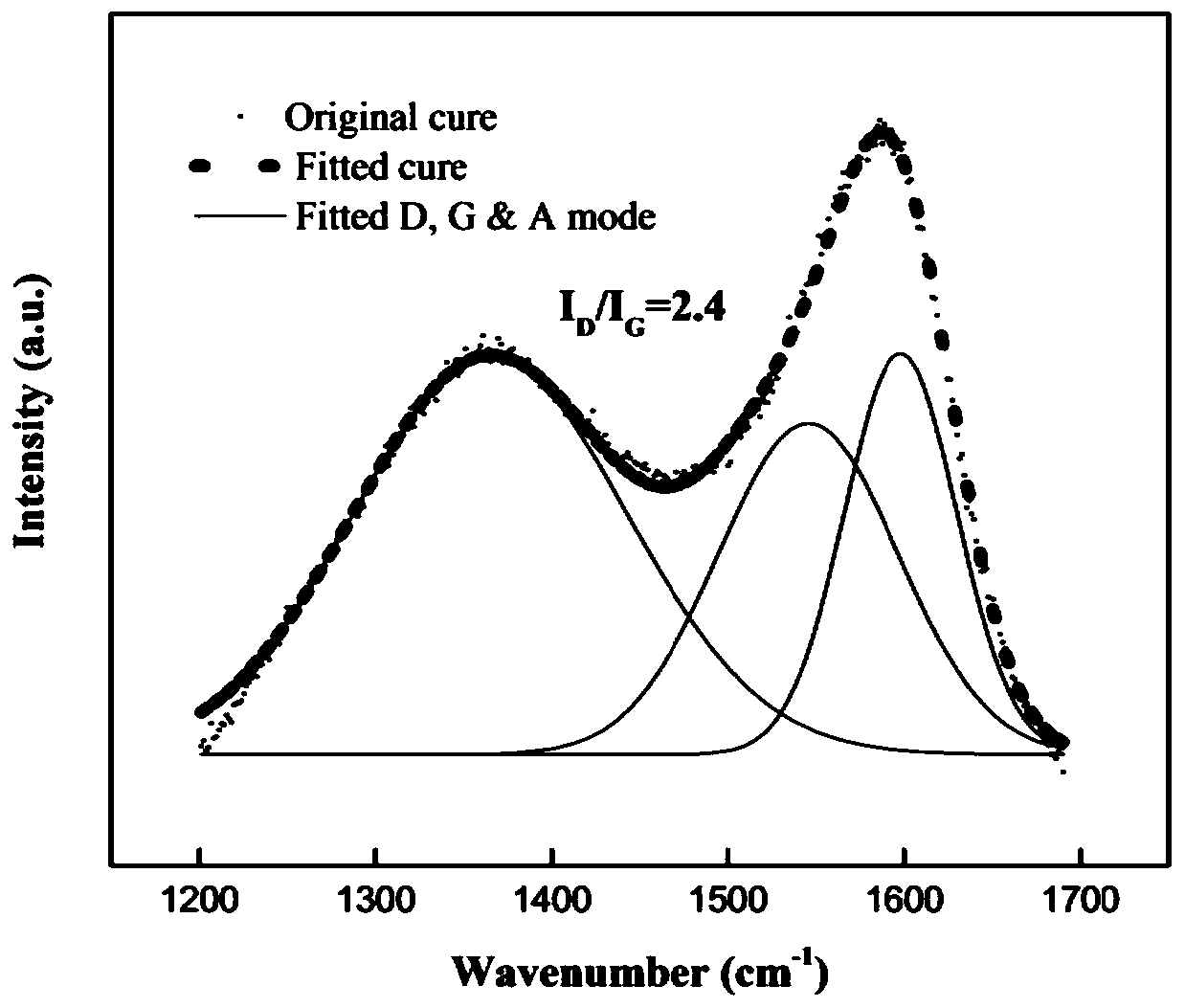

[0046] Further, the specific surface area of the carbon foam matrix deposited by the dop...

Embodiment 1

[0061] A method for preparing a carbon-based material provided by the present invention comprises the following steps:

[0062] Step 1, mixing starch and water according to the mass percentage of 1:1 to obtain preliminary materials;

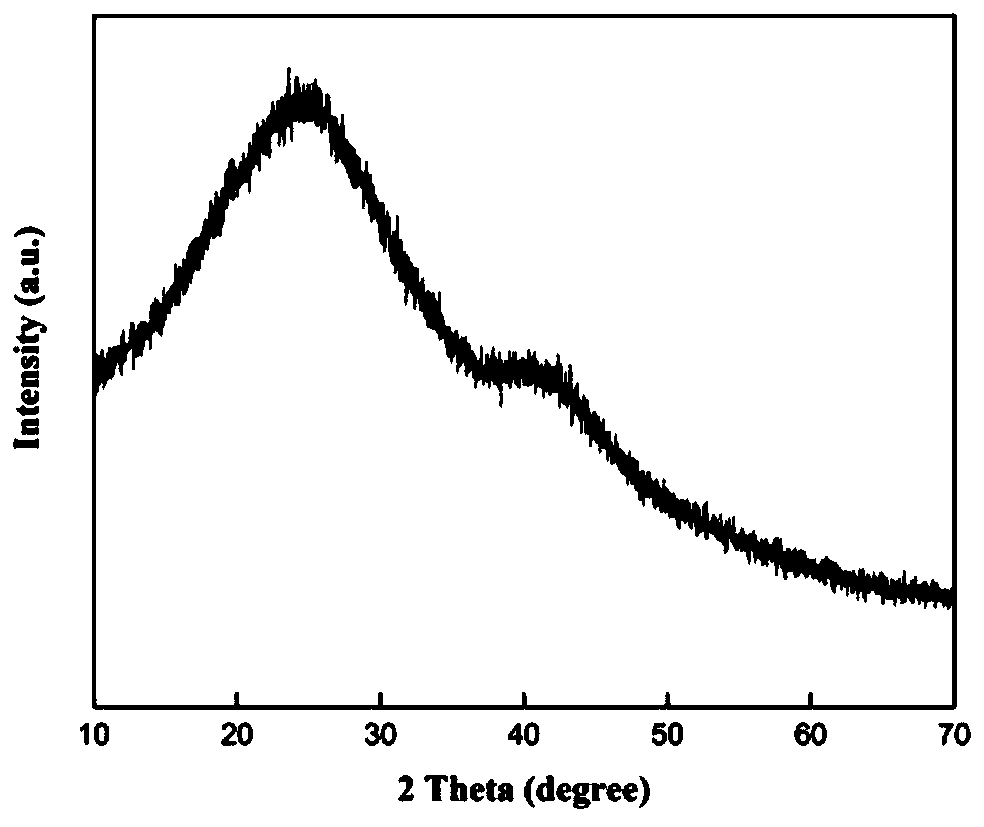

[0063] Step 2, freeze-drying the obtained preliminary material at -50°C for 20 hours; figure 2 is the microscopic morphology of the bulk material observed by XRD technology when it is not carbonized;

[0064] Step 3, performing high-temperature carbonization obtained in step 2 to make a carbon foam matrix;

[0065] There are three ways of high-temperature carbonization, choose one; the details are as follows:

[0066] (1) carbonization in argon, the temperature is 500°C, and the time is 1h;

[0067] (2) carbonization in air, the temperature is 300°C, and the time is 1h;

[0068] (3) Carbonization in vacuum at a temperature of 500° C. for 1 h.

[0069] Step 4, put the carbon foam matrix prepared in step 3 into the dopamine solution to soak f...

Embodiment 2

[0081] A method for preparing a carbon-based material provided by the present invention comprises the following steps:

[0082] Step 1, mixing starch and water according to the mass percentage of 1:1.2 to obtain preliminary materials;

[0083] Step 2, freeze-drying the obtained preliminary material at -50°C for 20 hours; figure 2 is the microscopic morphology of the bulk material observed by XRD technology when it is not carbonized;

[0084] Step 3, performing high-temperature carbonization obtained in step 2 to make a carbon foam matrix;

[0085] There are three ways of high-temperature carbonization, choose one; the details are as follows:

[0086] (1) carbonization in argon, the temperature is 800°C, and the time is 1.5h;

[0087] (2) carbonization in the air, the temperature is 500°C, and the time is 1.5h;

[0088] (3) Carbonization in vacuum, the temperature is 700°C, and the time is 1.5h.

[0089] Step 4, put the carbon foam matrix prepared in step 3 into the dopam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com