Microbial curing agent for soft clay, application of microbial curing agent to soft clay curing and application method of microbial curing agent

A soft clay and microbial technology, applied in chemical instruments and methods, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of large energy consumption, low permeability, environmental pollution, etc. The effect of solidification, stable oxygen production process and soil strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

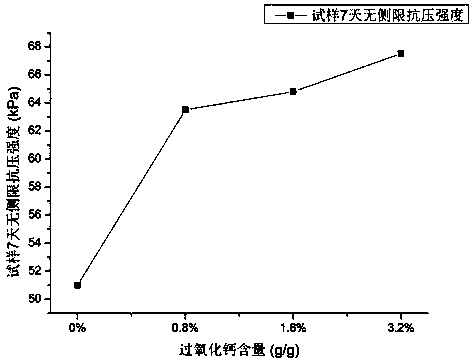

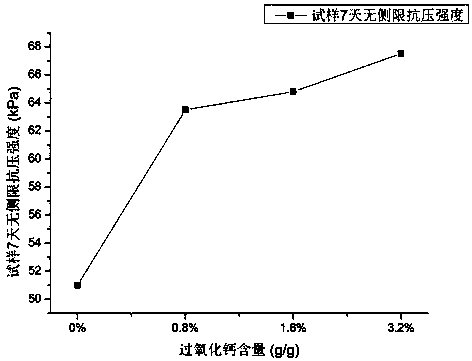

[0020] Embodiment 1: a kind of soft clay microbial curing agent, it is made up of the raw material of following parts by weight: 15 parts of urea, 27.6 parts of calcium chloride, 75 parts of Bacillus pasteurian bacteria liquid, 30 parts of oxygen enhancer calcium peroxide particles.

Embodiment 2

[0021] Embodiment 2: a kind of soft clay microbial curing agent, it is made up of the raw material of following parts by weight: 12 parts of urea, 25 parts of calcium chloride, 40 parts of Bacillus pasteurian bacteria liquid, 8 parts of calcium peroxide particles of oxygen enhancer.

Embodiment 3

[0022] Embodiment 3: a kind of soft clay microbial curing agent, it is made up of the raw material of following parts by weight: 18 parts of urea, 30 parts of calcium chloride, 120 parts of Bacillus pasteurian bacteria liquid, 200 parts of oxygen enhancer calcium peroxide particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com