Modified butadiene rubber, and preparation method and application thereof

A butadiene rubber modification technology, applied in the field of rubber modification, can solve the problems of low tear strength, puncture resistance and unsatisfactory resistance to chipping and chipping, and achieve good wet skid resistance and low rolling Good resistance, the effect of increasing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

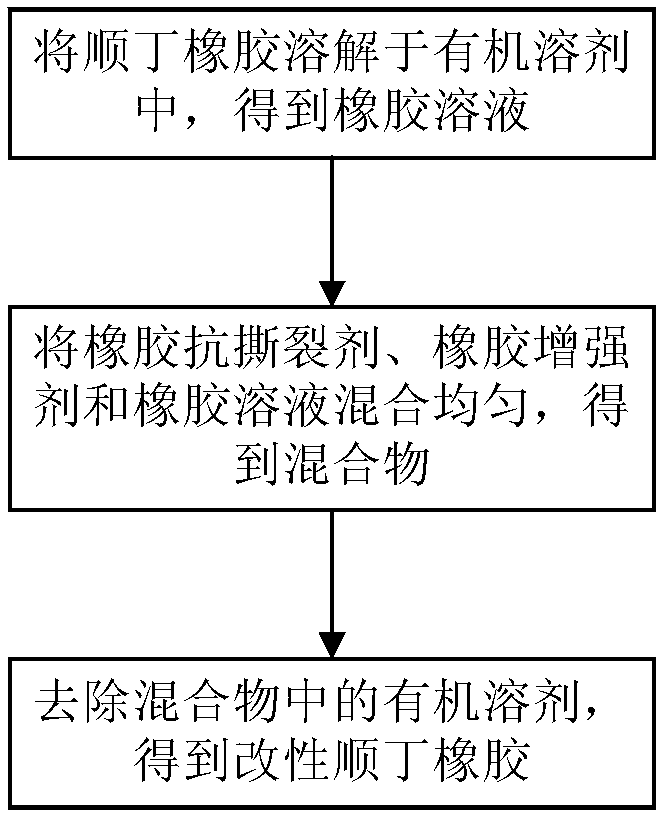

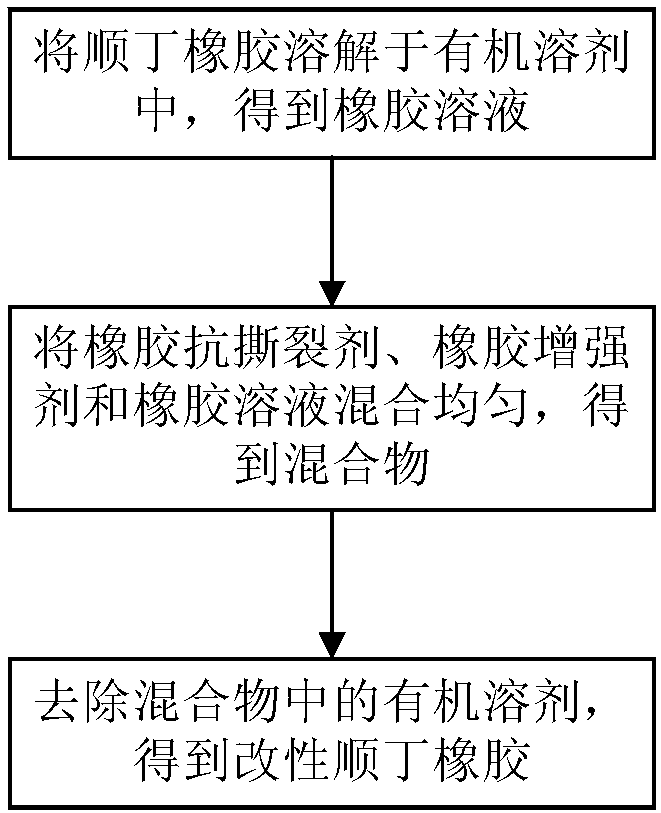

[0048] This embodiment provides a method for preparing modified butadiene rubber. See Table 1 for the specific process flow, including the following steps:

[0049] Dissolving 100 parts by weight of butadiene rubber in hexane to obtain a rubber solution, wherein the number average molecular weight of the butadiene rubber is about 82,000 and the molecular weight distribution index is 1.8;

[0050] Add 20 parts by weight of phenolic resin and 5 parts by weight of carbon black to the above-mentioned rubber solution, and stir uniformly to obtain a mixture;

[0051] Ethanol was added to the above mixture to separate the solid mixture composed of butadiene rubber, phenolic resin and carbon black into layers. After solid-liquid separation, the resulting solid mixture was heated and dried to further remove the organic solvent in it to obtain a modified Sexual butadiene rubber.

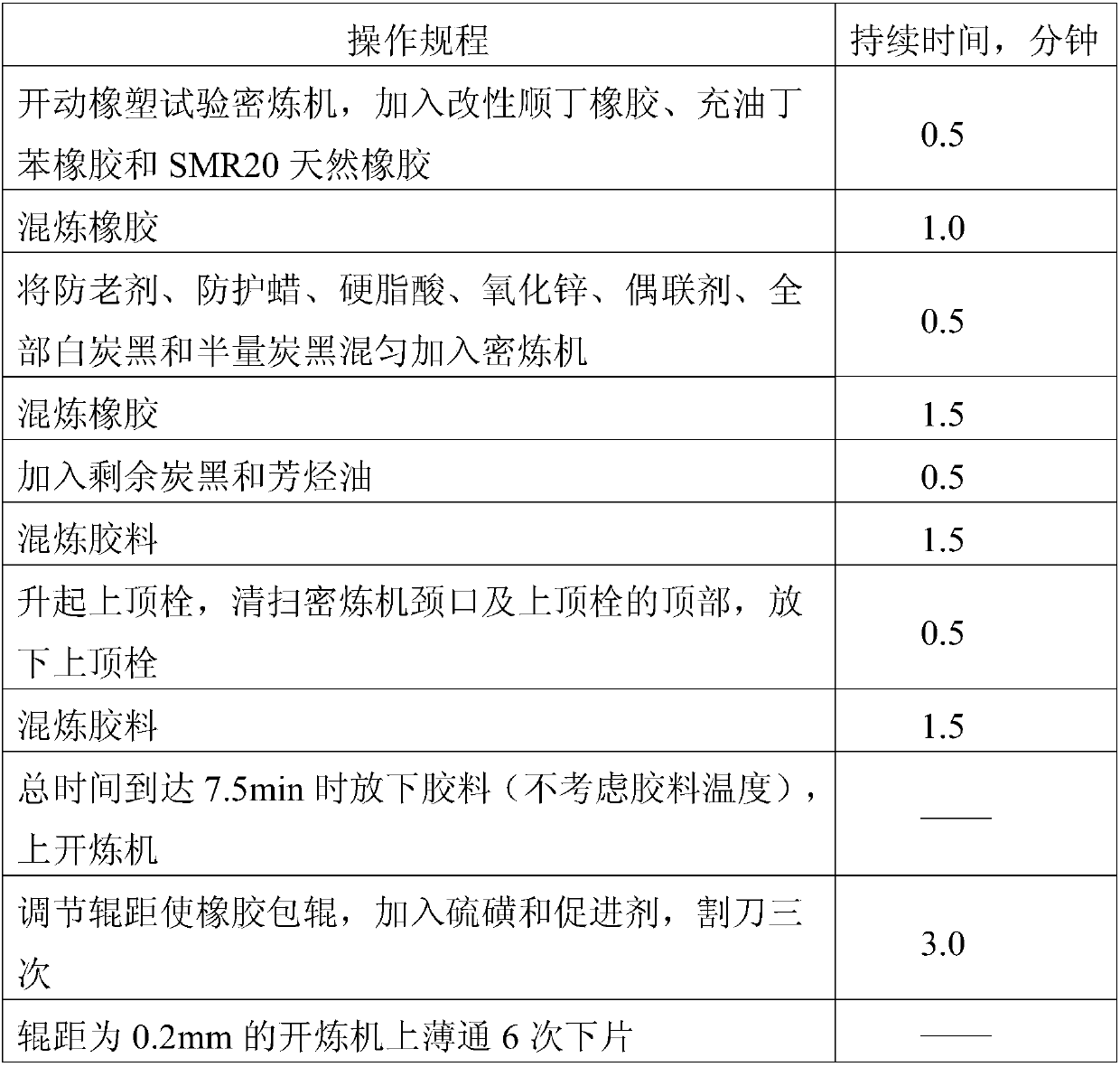

[0052] According to the standard test formula (non-oil-extended rubber) described in Table 1 in "GB / T 8660-2008 Sol...

Embodiment 2

[0060] This embodiment provides a method for preparing modified butadiene rubber. See Table 1 for the specific process flow, including the following steps:

[0061] 100 parts by weight of butadiene rubber was dissolved in toluene to obtain a rubber solution, wherein the number average molecular weight of the butadiene rubber was about 105,000 and the molecular weight distribution index was 2.0.

[0062] Add 25 parts by weight of terpene resin and 6 parts by weight of white carbon black to the above rubber solution, stir evenly to obtain a mixture;

[0063] Methanol is added to the above mixture to separate the solid mixture composed of butadiene rubber, terpene resin and white carbon black into layers. After solid-liquid separation, the resulting solid mixture is heated and dried to further remove the organic solvent. The modified butadiene rubber is obtained.

[0064] According to the formula and method in Example 1, the modified butadiene rubber in this implementation was mixed and ...

Embodiment 3

[0072] This embodiment provides a method for preparing modified butadiene rubber. See Table 1 for the specific process flow, including the following steps:

[0073] 100 parts by weight of butadiene rubber is dissolved in tetrahydrofuran to obtain a rubber solution, wherein the number average molecular weight of the butadiene rubber is about 112,000 and the molecular weight distribution index is 3.5.

[0074] Add 30 parts by weight of carbon five petroleum resin and 8 parts by weight of calcium carbonate to the above rubber solution, and stir the mixture to obtain a mixture;

[0075] Ethylene glycol is added to the above mixture to separate the solid mixture composed of butadiene rubber, carbon five petroleum resin and calcium carbonate into layers. After solid-liquid separation, the resulting solid mixture is heated and dried to further remove the organic Solvent to obtain modified butadiene rubber.

[0076] According to the formula and method in Example 1, the modified butadiene rubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com