Coated chlorobutyl rubber plug and preparation method thereof

A technology of chlorobutyl rubber and film-coated chlorobutyl rubber, which is applied in the field of film-coated chlorobutyl rubber stoppers and its preparation, and can solve the problem of compatibility between rubber stoppers and drugs and the inability to meet the requirements of low shedding , Reduce the self-sealing of rubber plugs and other problems, to achieve the effect of preserving elasticity and sealing, good mechanical strength and elasticity, good mechanical properties and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention also provides a kind of preparation method of film-coated chlorinated butyl rubber stopper, comprises the steps:

[0032] (1) prepare materials by weight;

[0033] (2) Divide the chlorinated isoprene isobutylene rubber into four parts, mix the first part of the chlorinated isoprene isobutylene rubber with the coloring agent uniformly to obtain product A; mix the activator and filler uniformly to obtain product B ; Mix the second part of chlorinated isoprene isobutylene rubber with crosslinking agent uniformly to obtain product C; mix the third part of chlorinated isoprene isobutylene rubber with activator to obtain product D; After chlorinated isoprene isobutylene rubber and product A are mixed evenly, add 1 / 3 of product B to the above mixed product, mix again, then add 2 / 3 of product B and product C to the above mixed product, mix After uniformity, add product D to the above mixed product and mix uniformly to make a preformed bo...

Embodiment 1

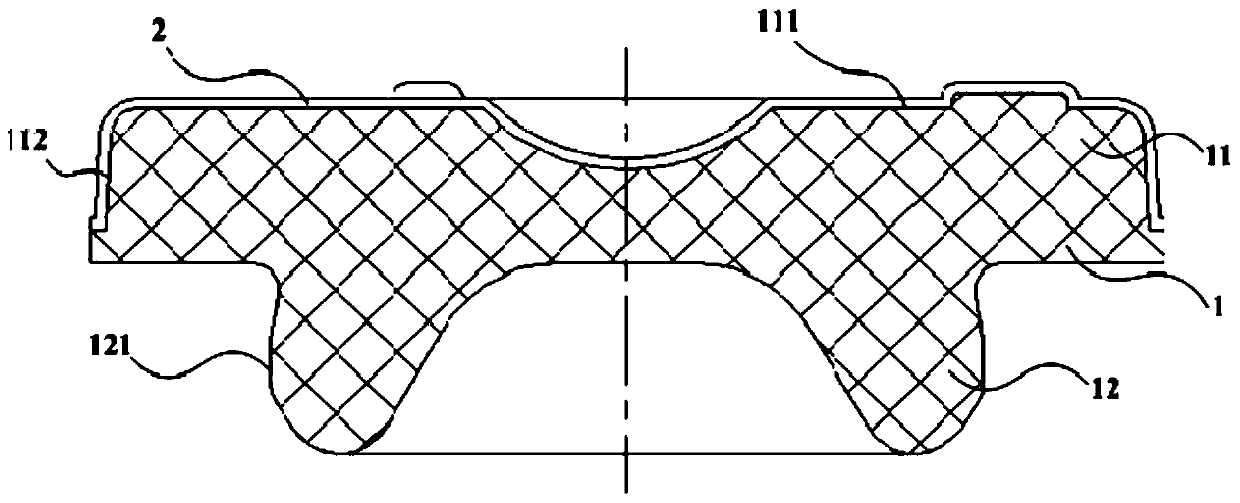

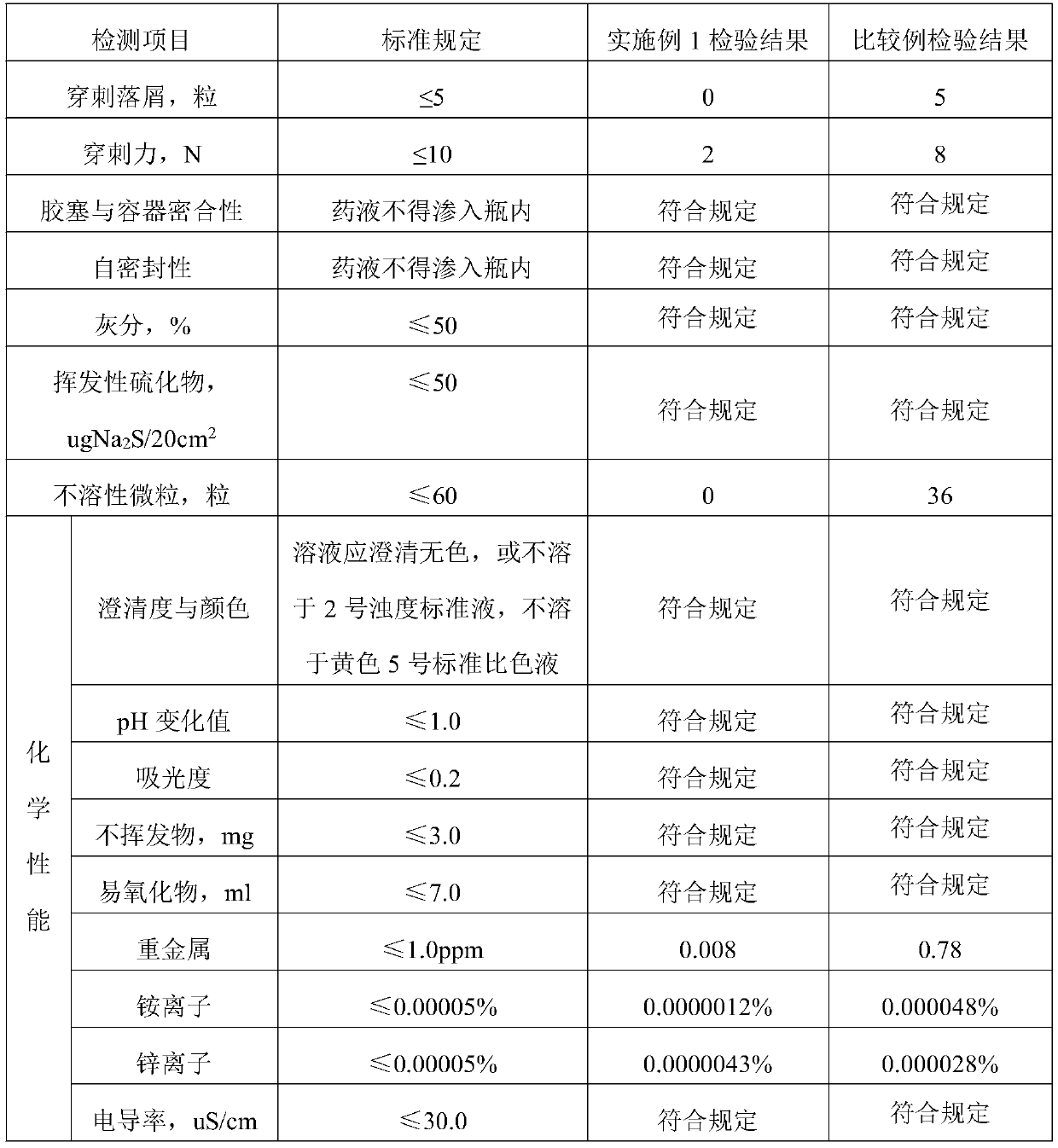

[0040] Embodiment 1 of the present invention provides a film-coated chlorinated butyl rubber stopper, the chlorinated butyl rubber stopper main body includes the following raw materials in parts by weight: 100 parts of chlorinated isoprene isobutylene rubber, 6-(diethyl 0.9 parts of amino)-1,3,5-triazole-2,4-dithiol, 40 parts of white carbon black, 0.15 parts of carbon black, 2 parts of zinc oxide and 0.4 parts of titanate. Among them, isochloride The viscosity-average molecular weight of pentadiene isobutylene rubber is 150,000, the Mooney viscosity ML 1+8 (100°C) is 45, the degree of unsaturation is 1.3mol%, and the content of chlorine is 1wt%; the crown and neck of the main body There is an ethylene-tetrafluoroethylene copolymer film on the top, the melting point of the ethylene-tetrafluoroethylene copolymer is 265 ° C ~ 275 ° C, the continuous working temperature is 150 ° C, the embrittlement temperature is -100 ° C, the ethylene-tetrafluoroethylene copolymer at the crown ...

Embodiment 2

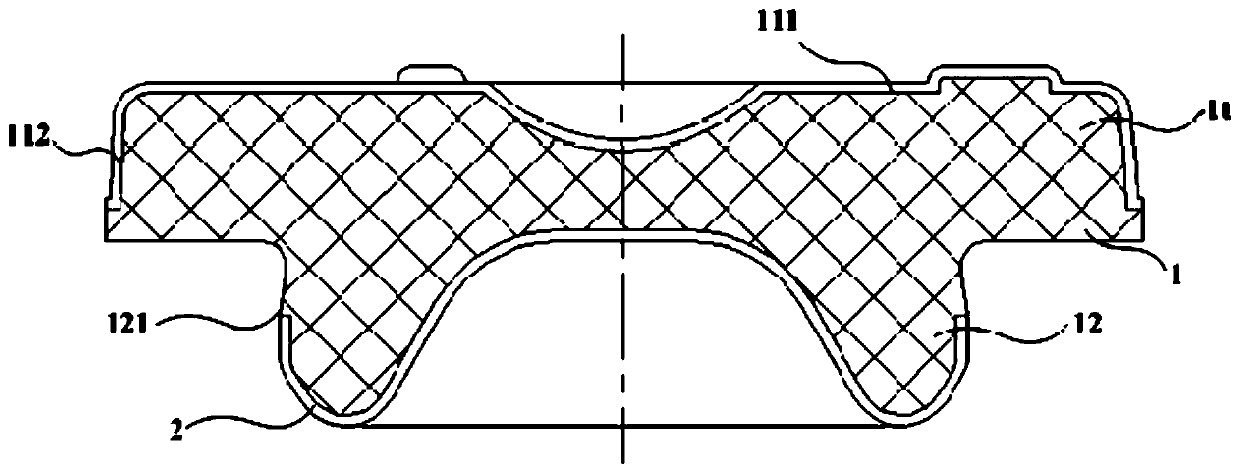

[0047] Embodiment 2 of the present invention provides a film-coated chlorinated butyl rubber stopper, the chlorinated butyl rubber stopper main body includes the following raw materials in parts by weight: 90 parts of chlorinated isoprene isobutylene rubber, 6-(diethyl 0.8 part of amino)-1,3,5-triazole-2,4-dithiol, 30 parts of white carbon black, 0.1 part of carbon black, 1 part of zinc oxide and 0.3 part of titanate. The viscosity-average molecular weight of pentadiene isobutylene rubber is 120,000, the Mooney viscosity ML 1+8 (100°C) is 100, the degree of unsaturation is 3mol%, and the content of chlorine is 3wt%. All are equipped with ethylene-tetrafluoroethylene copolymer film, the melting point of the ethylene-tetrafluoroethylene copolymer is 265 ° C ~ 275 ° C, the continuous working temperature is 150 ° C, the embrittlement temperature is -100 ° C, the ethylene-tetrafluoroethylene copolymer of the crown is The thickness of the fluoroethylene copolymer film is 20um, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com